Product Introduction

There is a new project of Infinity aluminum enclosure from our customer, the enclosure needs to be made from aluminum material by die casting process.

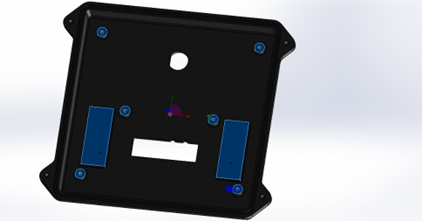

First, we analyzed the drawings, the products have a top cover and a bottom cover. The top cover is made from aluminium alloy by die casting, need processing and milling. The bottom cover is a plate, we prepare to stamping out directly, then planish, this is a pretty simple process. The final product needs to be powder coated and the logo will be laser engraving.

Material and process

This enclosuer is made from aluminum material. Aluminum's low density reduces weight compared to steel or zinc, making it ideal for portable devices.

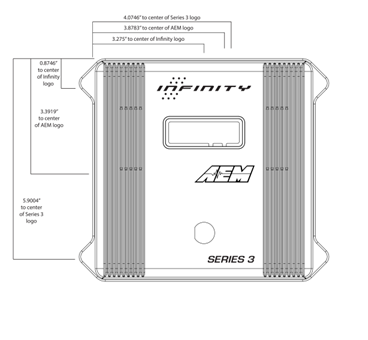

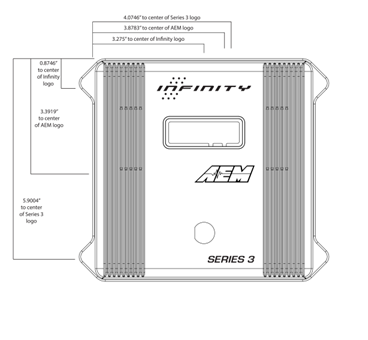

Here is the drawings:

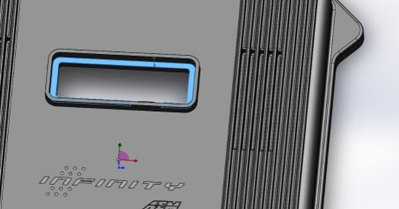

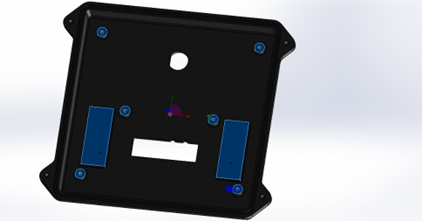

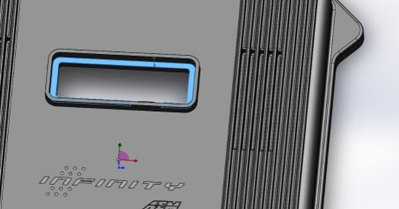

There are some positions need to be machined, we confirmed the exact place after analizing, then we will leave a machining allowance in the mold design. Some threads in blue on the top cover as below pictures will be machined:

Next step is mold making. The base material is H13, typically high-grade tool steel. For high-volume production, pre-hardened steels are preferred to withstand repeated cycles. Raw steel blocks are cut to approximate dimensions using sawing or plasma cutting, ensuring they fit within machining equipment tolerances.

Large stock blocks undergo rough machining to remove excess material, shaping the mold's outer frame, cavities, and core structures. 3-axis CNC machines can finish precise cutting, reducing the workpiece to near-final dimensions with minimal material waste. For intricate geometries that are hard to mill, wire EDM is used.

The mold's surfaces are ground to achieve flatness, smoothness, and tight tolerances. To enhance hardness and wear resistance, the mold components are heat-treated.

Here is our die casting factory overview:

It has different districts, so the enclosure will be die casted first and deburrs, then machining the specific position.

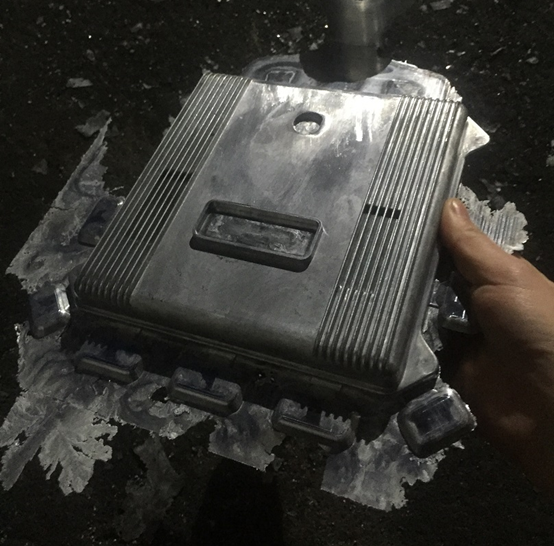

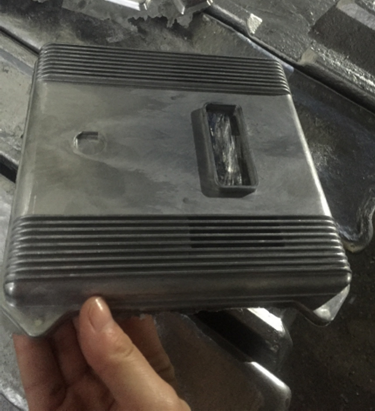

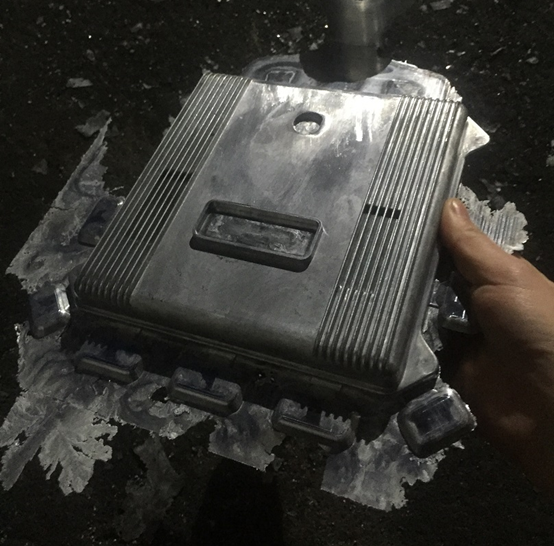

Here are the rough parts after die casting, the mold is 1-1 cavity. The rough product has a feeding port and burrs, all of which need to be removed and can also be recycled:

the enclosure rough parts 1

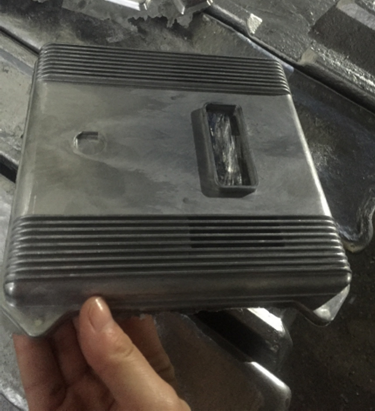

the enclosure rough parts 2

the enclosure rough parts 3

After deburrs:

However, there are still many burrs, flash, then we need to grinding wheel grinding.

After that, they are sent for sand blasting.

Then conduct the inspect of surface first time, mainly check the part surface if have defect or bump. The qualified parts were sent for black powder coated.

There is second inspection when the powder coated finished, mainly for the flaws.

Products with flaws in appearance all need to be picked out and reworked or scrapped.

Next, CNC milling is carried out on the products.

The threads at the other four corners are blind holes M4. The product thickness is 6.3mm, and the thread depth is required to be 4mm, which is very easy to break. We use the manual tapping method, to ensure safety.

Then we use thread gauge to inspect the thread.

Finally they are undergone laser marking process.

Packing

This product has high surface requirements, so we adopt a multi-layered packaging to ensure its protection. Each unit is first wrapped individually in a bubble bag, then carefully placed into cardboard cartons. Once the boxes are packed and sealed, they are put on pallets.

The entire pallet undergoes wrapping with stretch plastic film. This not only adds a barrier against dust, moisture, and external debris but also reinforces the stability of the entire load, keeping everything tightly bound.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски