Product Introduction

A fuel rail, a key component in an internal combustion engine's fuel injection system, is a tubular metal structure that stores high-pressure fuel from the pump, stabilizes its pressure, and evenly distributes it to the injectors of each cylinder. Made of aluminum or steel, it ensures consistent fuel delivery for optimal combustion efficiency, and its design varies for gasoline and diesel engines, with modern innovations focusing on lightweight materials, integrated sensors, and compact configurations to enhance performance and reliability.

Material and process

This is made from aluminum 6061 material or 6082 billet. Aluminum alloy is renowned for its low weight, with a density of approximately 2.7 g/cm³—about one-third that of steel. Given its complex structure, a 4-axis CNC machine is the most suitable equipment for processing, enabling precise machining of intricate geometries and ensuring dimensional accuracy for demanding applications.

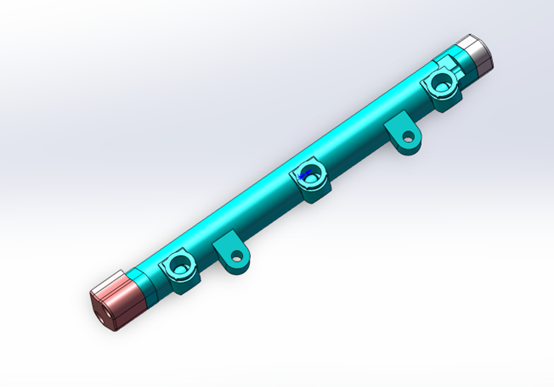

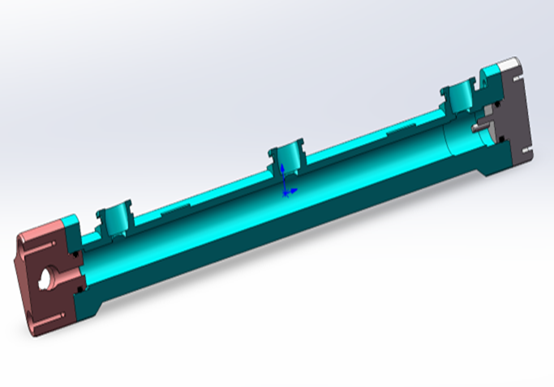

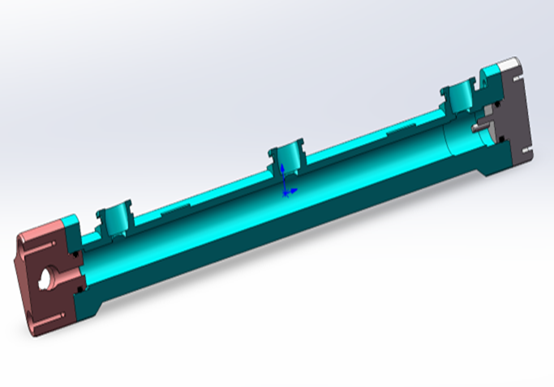

The 3D drawings as followings:

fuel rail 3D drawing-1

fuel rail 3D drawing-1

The length of the fuel rail is over 300mm, it's too long to machine, so we choose to drill the holes on the 2 ends.

The central pipe is machined by milling, and in addition, connectors at both ends also need to be processed. During the machining, 4-axis CNC equipment can be used to ensure the coaxiality and dimensional accuracy of the pipe and connectors.

For the connectors, operations such as turning, milling, and drilling are required to machine interfaces like threads or flanges, so as to achieve precise assembly with other components. This integrated machining process ensures the structural integrity and functional reliability of the entire part.

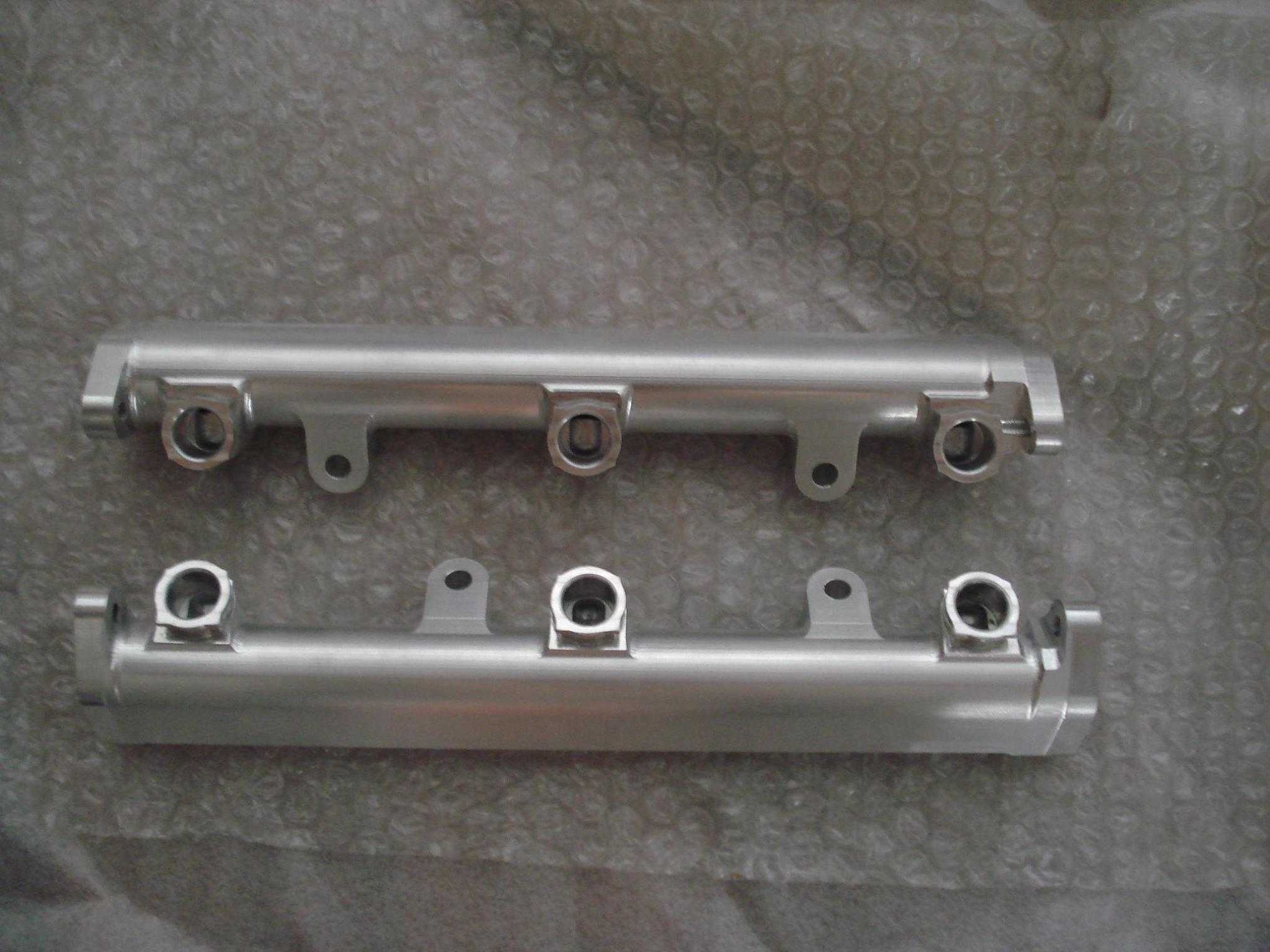

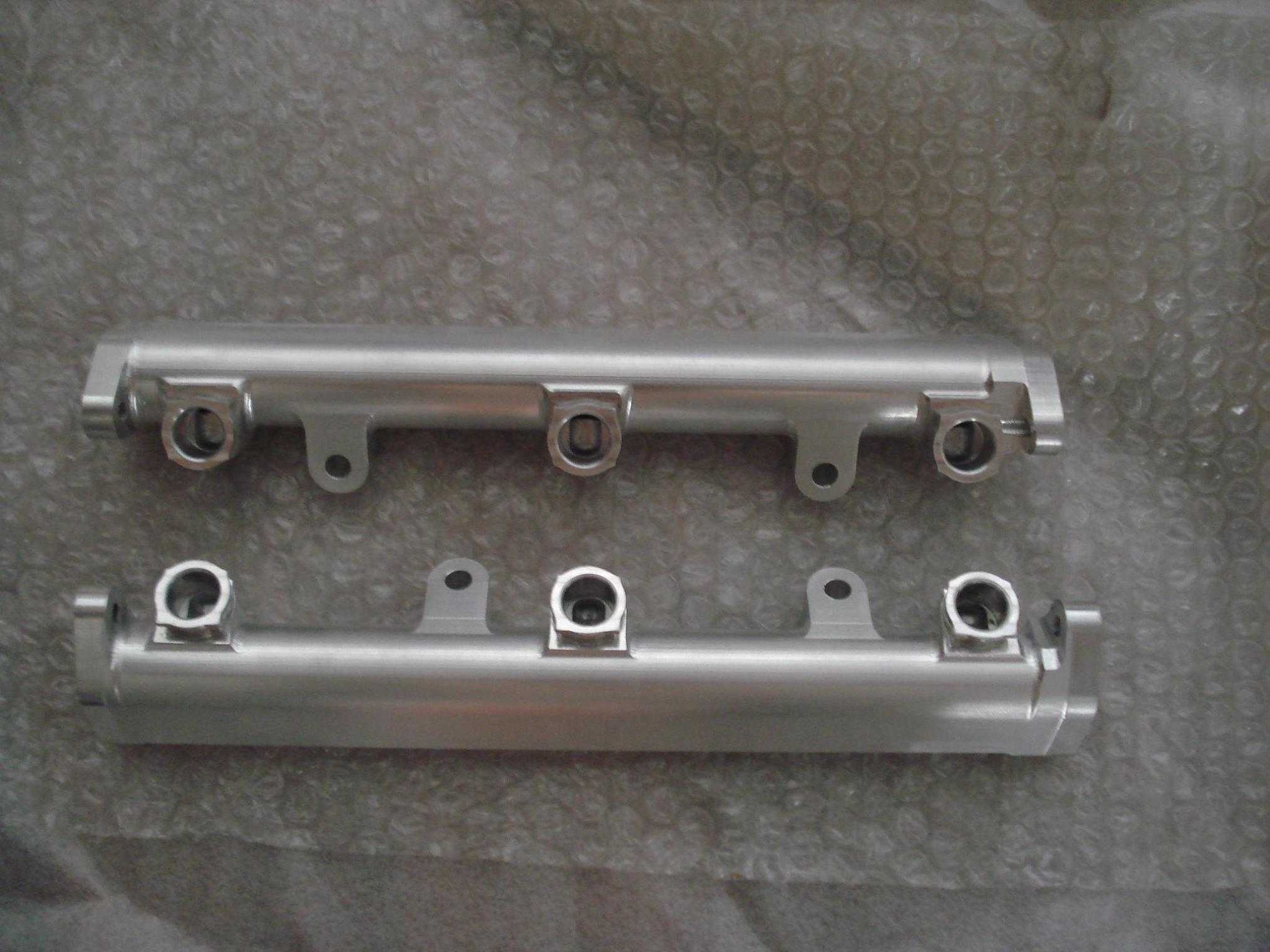

Then the parts are finished.

And with fuel rail adapter.

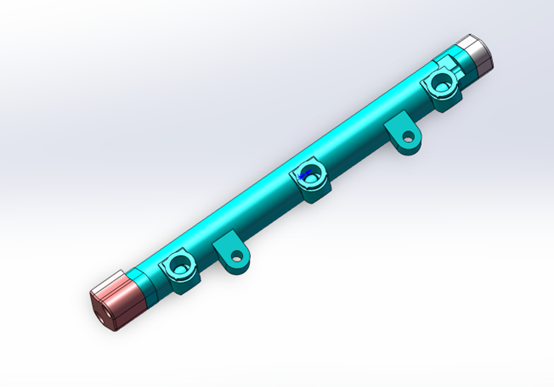

After full assembly, the client was highly satisfied, which led to a new order for other styles of fuel rails. The subsequent order indicates trust in our capability to handle varied fuel rail configurations, from structural complexity to functional specifications, ensuring consistent performance across different models.

another style fuel rail-1

another style fuel rail-2

Then fuel rail test fitment.

At this point, the project has come to an end successfully.

Apart from this, we have worked many kinds of fuel rails.

Ningbo Joyo Metal Products Co., Ltd. possesses strong capabilities in customizing various fuel rails, catering to diverse technical requirements and application scenarios. With a focus on precision, material expertise, and rapid customization, we enable clients to transform unique fuel rail designs into high-quality, functional components—proven by successful projects spanning diverse industries.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски