Product Introduction

The nickel alloy 718 2-layer gasket is made by stamping process and used in automotive industry. The two-layer structure of the gasket is designed to enhance its sealing performance, or to meet specific application requirements.

Material and process

This part is made of special material, nickel alloy 718. Nickel Alloy 718 is a precipitation-hardened nickel-based superalloy, it has excellent high-temperature strength, corrosion resistance, and weldability. It is extremly hard material to punch, also this nickel alloy material has excellent ability to resist rusty.

We possess quality certification documents for this material (Nickel Alloy 718), which are issued by authoritative third-party institutions and strictly comply with international standards. Nickel Alloy 718 is available in various forms, including rolls and plates, finally we choose the thickness of 0.25mm sheet to work the gasket. As the pictures shows:

material of 718 quality certificated

roll of material nickel alloy 718

thickness 0.25mm 718 sheet

Then the material is arrived and cut into pieces.

50kgs of mateiral 718 nickel alloy arrived

cut the sheet into pireces

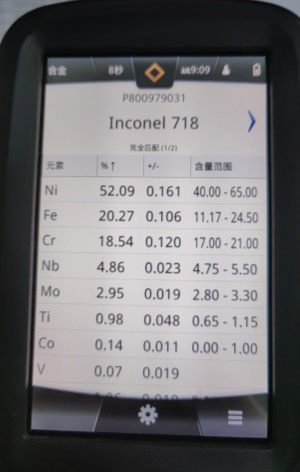

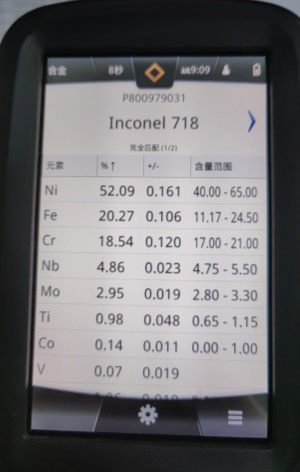

When the materials arrived, we conducted chemical composition test and hardness test on them, as shown in the images below.

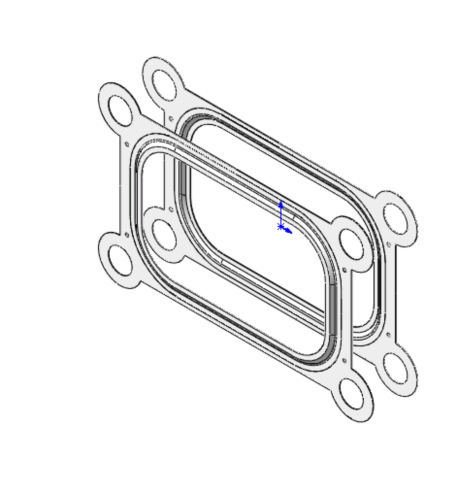

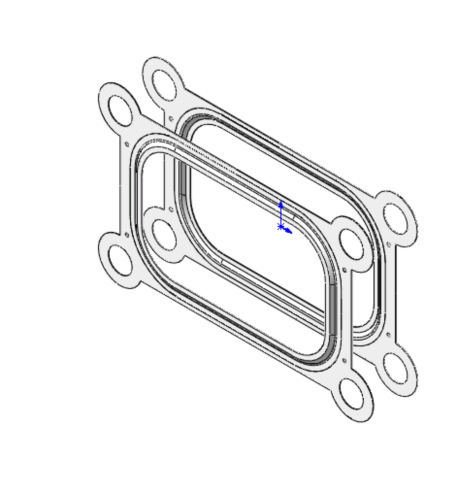

The gasket 3D drawings is from our costomer, and decided to perform punching process to work the product after our engineers analysing it.

For normal stainless steel, the regular process is to punch the outline first, then deep drawn the center rib.

But for the special hard material, the safe process is to deep drawn the center rib first, the punch the outline, or it will twist. After succeed, then put two plate spot welding together. The finished 718 gasket as the below picture.

Packing

After inspecting the product dimensions, we proceed with packaging. These finished gaskets were put into boxes and laid the boxes on the pallet, wrapped protective film around the box and pallet. This process ensures products are protected against transit damage.

In addition, there are different type of gasket developed by our factory.

Ningbo Joyo Metal Parts Co,.Ltd. is a professional custom metal parts manufacturer with more than 14 years experience, not only can master all kinds of processes, but also specialize in various material, such as aluminum alloy, steel, stainless steel, zamak, nickel and so on. We can also integrate various different process to satisfy one-stop services.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски