Product Introduction

This exhaust manifold is made from stainless steel material by precision casting process. By leveraging the strength of stainless steel and the flexibility of custom casting, these manifolds deliver reliable performance, longevity, and tailored functionality, making them a cornerstone of high-performance exhaust systems.

Material and process

304 stainless steel is the good choice for making the exhaust manifold. It offers excellent corrosion resistance and moderate heat resistance, ideal for street-legal vehicles or applications with lower exhaust temperatures.

Below are the samples from our customer:

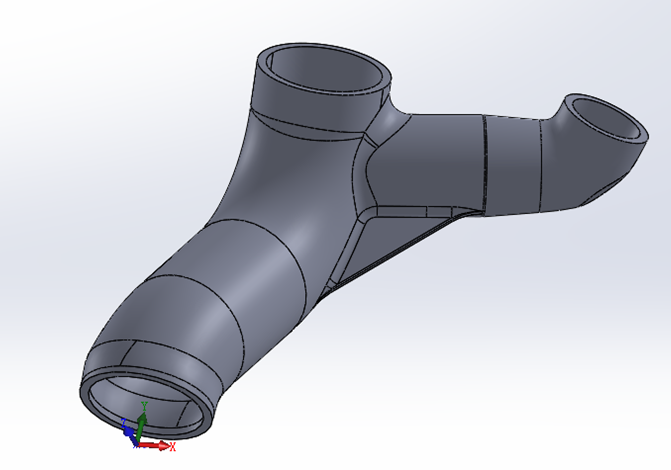

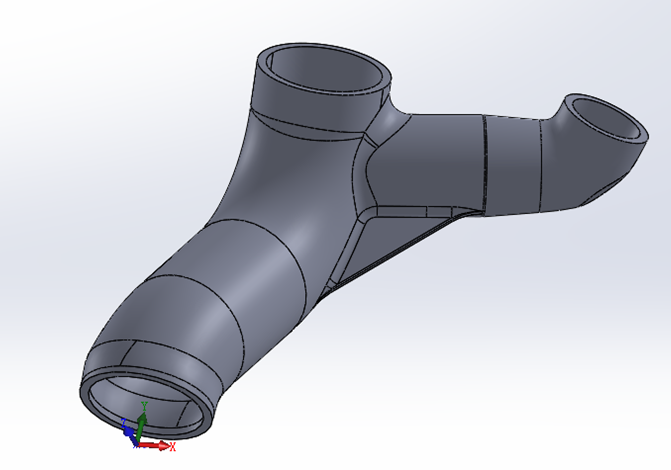

Then we scan and analyze the manifold to make the 3D drawings:

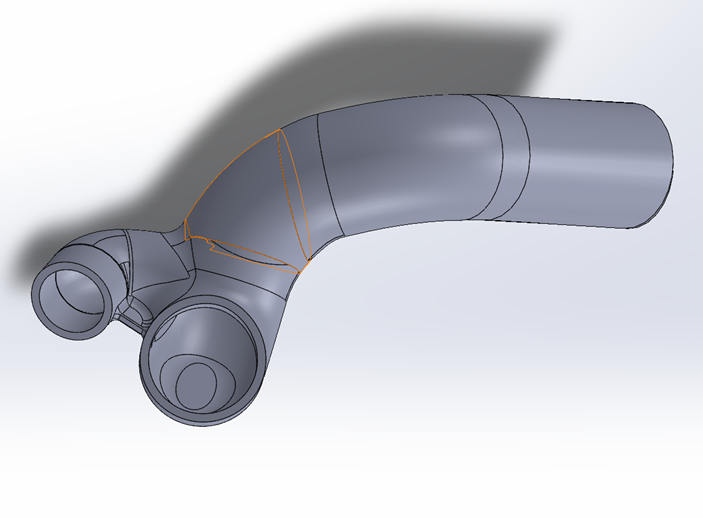

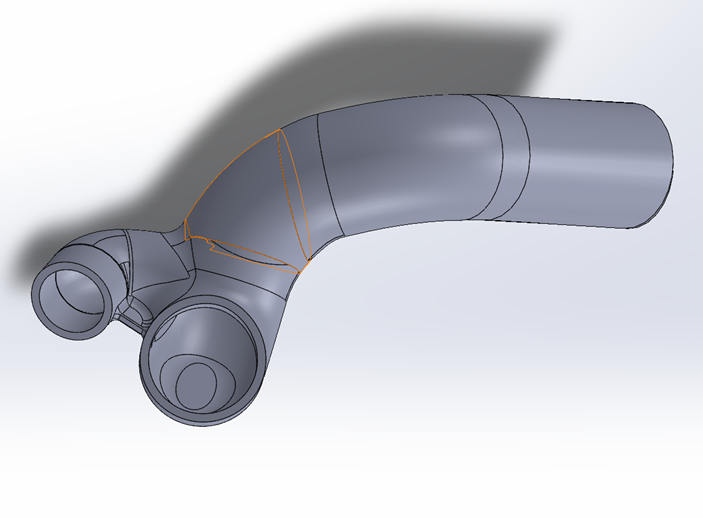

Next the prototype are worked by 3D printing, the 3D-printed prototypes replicate intricate details, complex geometries, and key features of the intended product, allowing clients to physically inspect surface finishes, assembly interfaces, and structural contours. We offer 3D-printed prototypes for client confirmation, serving as a critical step to validate design feasibility, dimensional accuracy, and functional fit before moving to mass production.

Here is the 3D printed manifold:

The stainless steel is same as lost wax casting process, the wax pattern mold and the wax pattern need to be made first.

Wax is injected into a metal mold under pressure, forming precise patterns, including intricate features like thin walls, holes, or contours. For complex parts, multiple wax patterns may be assembled onto a central wax sprue.

The wax assembly is dipped into a slurry of fine refractory materials mixed with a binder, then coated in coarse refractory grains to form a layer. This dipping and coating cycle repeats 5–10 times, building up a strong, heat-resistant ceramic shell around the wax. Each layer is dried to ensure adhesion, resulting in a shell thickness of 5–10 mm.

After the shell are fully dried, the assembly is placed in a oven, where heat melts the wax, which drains out through the sprue. This leaves a hollow ceramic cavity that exactly mirrors the wax pattern's shape. The shell is then fired in a high-temperature furnace to remove residual wax, strengthen the shell, and improve its thermal stability.

The molten metal is then poured into the preheated shell, to ensure complete filling of the cavity without turbulence or air entrapment. After the metal solidifies and cools, the shell removal step involves breaking the shell using mechanical vibration, revealing the rough casting. The sprue and any excess metal are cut off, and critical surfaces are machined and ground to meet tight tolerances.

Here are the pictures of the finished manifold with shot blasted surface:

Packing

Each exhaust manifold is individually packed in a bubble bag and then place them into wooden cases. This dual-layer packaging ensures comprehensive protection, the bubble bag acts as a cushion to absorb shocks and prevent scratches during transportation, while the sturdy wooden case provides structural support to resist external pressure and keep the manifolds securely positioned. Such packaging is designed to safeguard the exhaust manifolds.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски