Product Introduction

The custom casting engine head is made from gravity casting, also known as permanent mold casting, is significant to achieving the dimensional accuracy. Whether for racing engines, industrial power units, or automotive applications, our custom aluminum A356-T6 engine head gravity casting possesses the precision, strength, and thermal performance.

Material and process

Material advantages

A356-T6 is the material for the engine heads, it is enable to withstand the cyclic mechanical stress of valve operations and pressure after T6 heat treatment. And aluminum can dissipate heat from combustion chambers, reducing the risk of overheating and ensuring stable engine operation under high loads.

Drawings analysis

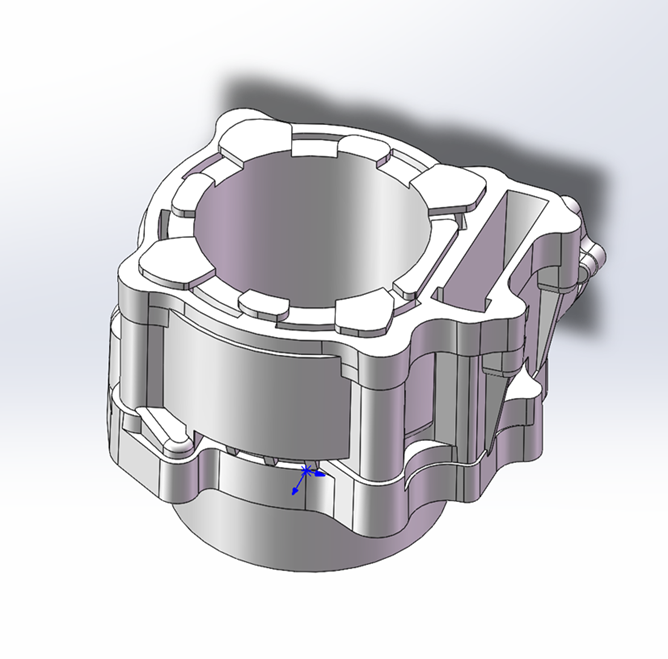

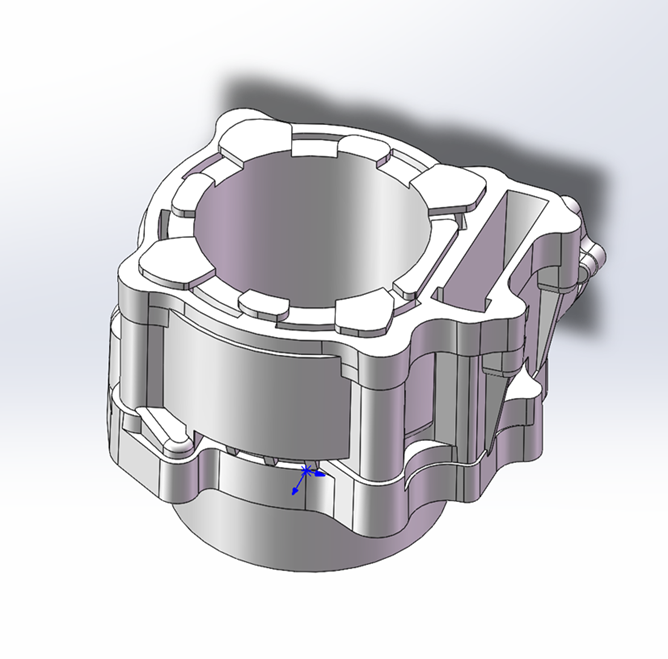

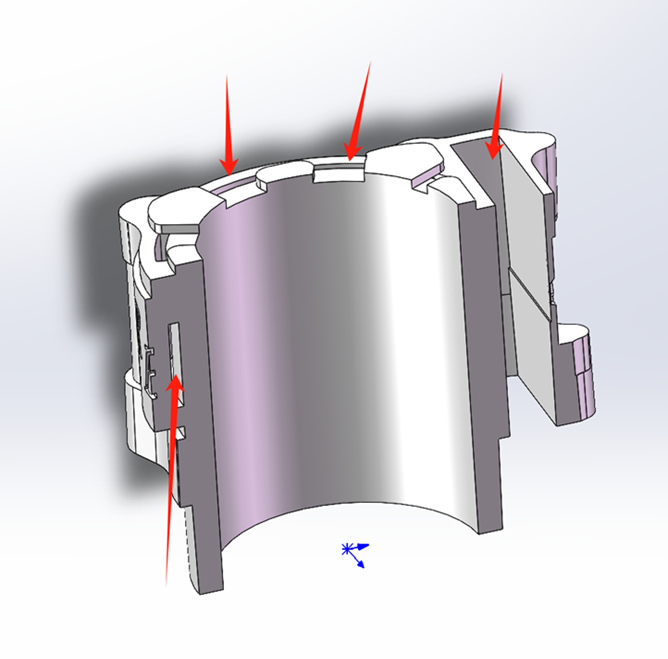

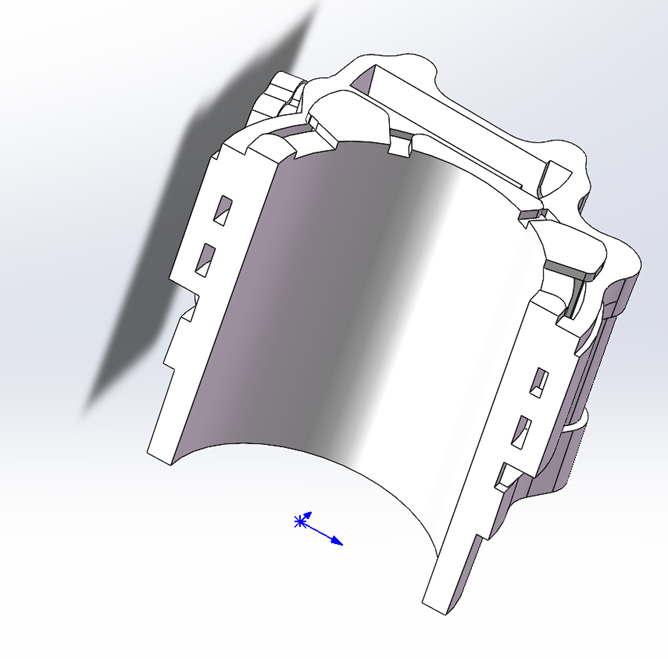

Here are the engine head 3D drawings:

the engine head 3D drawings -1

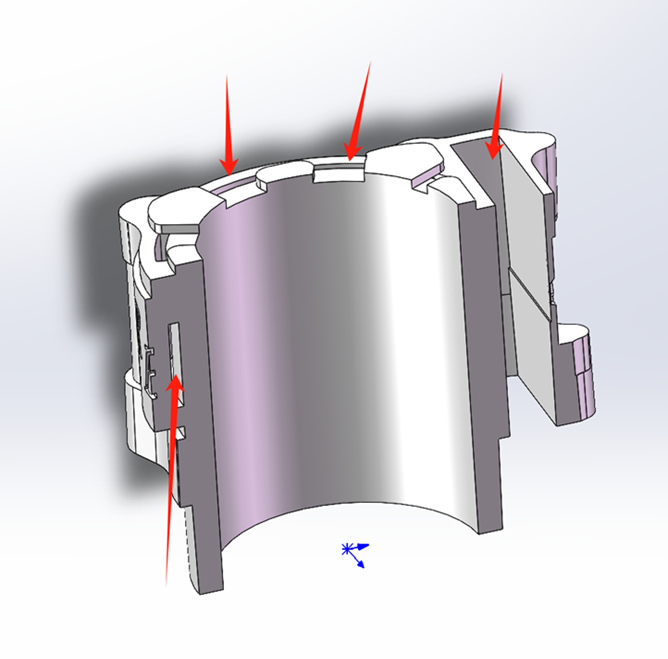

the engine head 3D drawings -2

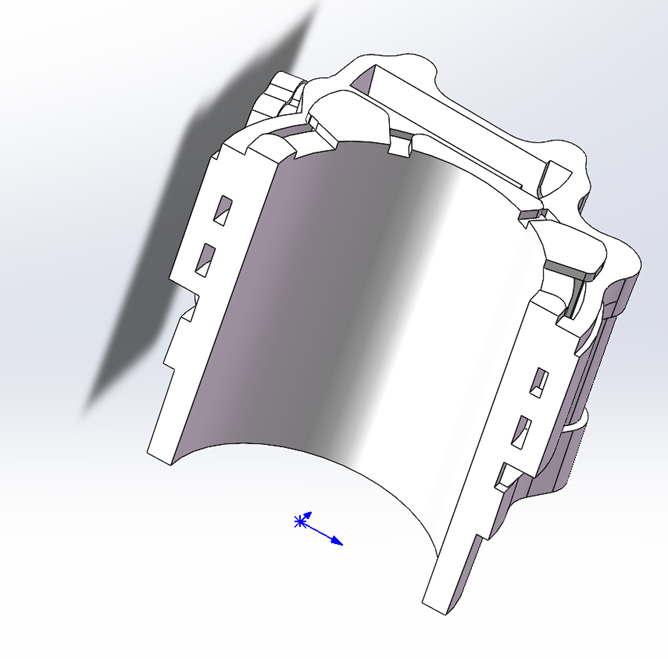

the engine head 3D drawings -3

Once the drawings are finalized, we begin the production for this parts, which weighs 2.4kg, with speciality in its core: the small internal cavities as those pointed by the red arrows.

Manufacturing Process

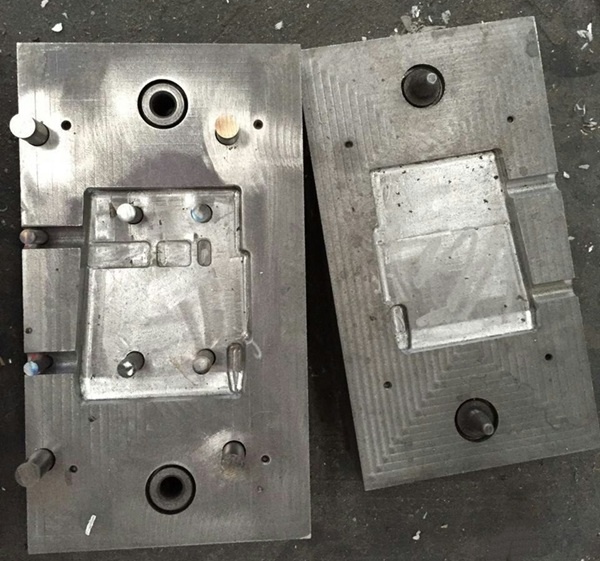

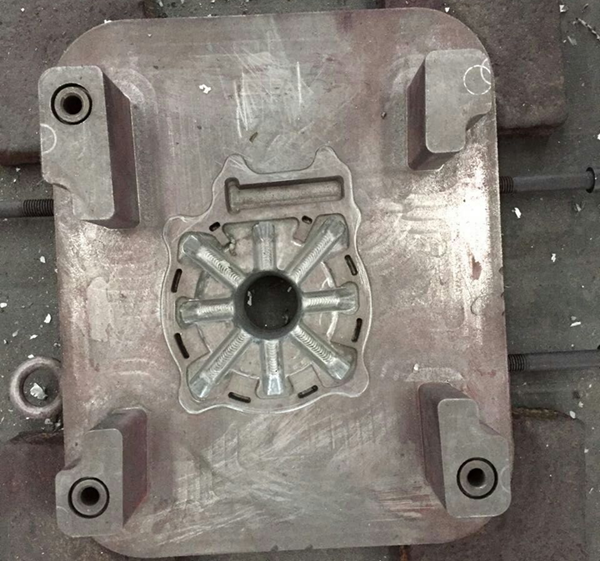

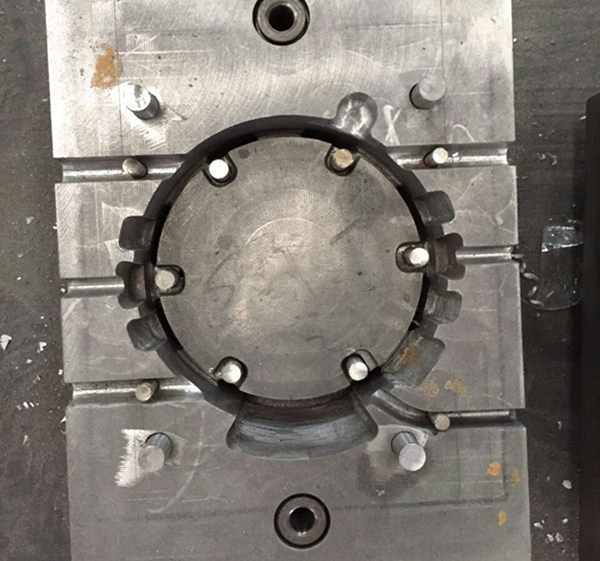

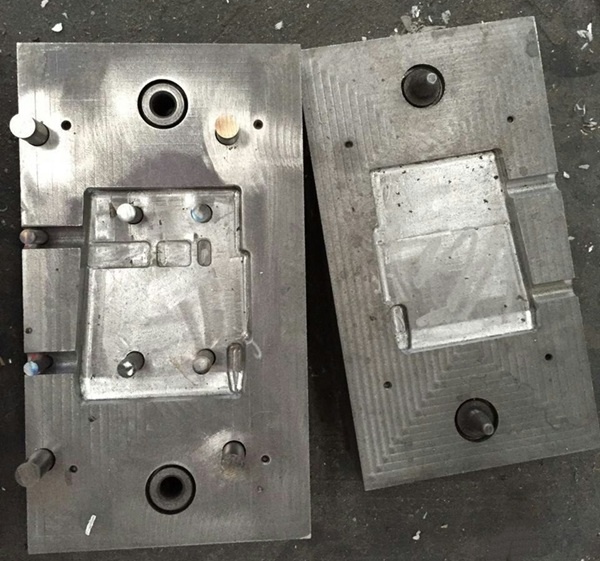

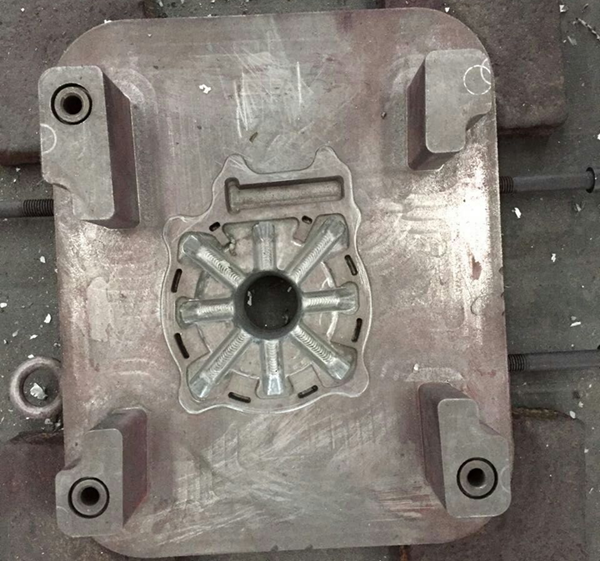

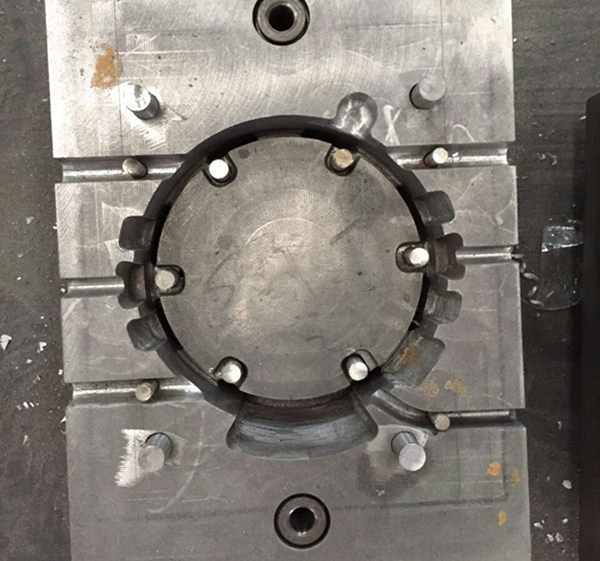

Just as its name implies, permanent mold casting needs a mold. So the mold is need to make first. Molds are precision machined by high grade tool steel. Below are the molds of the engine head:

aluminum engine head mold-1

aluminum engine head mold-2

aluminum engine head mold-3

aluminum engine head mold-4

Then install the mold and test, the permanent mold is first cleaned and preheated to a certain temperature. Preheating ensures proper metal flow, prevents cold shuts, and extends mold life. The A356 aluminum material is melted in a furnace. The molten metal is then poured. Gravity guides the metal through runners and gates into the mold's cavities, filling all details. Once filled, the mold and metal are allowed to cool. Cooling rates are controlled to avoid internal stresses or defects: thicker sections may cool more slowly, while thin walls solidify faster. After solidification, the mold is opened, and the casting is removed.Below is the rough casting engine head:

Post-casting steps include trimming excess material, heat treatment T6 to enhance strength, and sandblasted.

Packing

Prior to packaging, we conduct inspections on the dimensional accuracy and surface quality. For qualified products, they are wrapped tightly in bubble to provide cushioning and protection, against scratches or impacts during transit. These wrapped items are carefully placed into sturdy cartons, the cartons are securely loaded onto pallets, to ensure stability during handling and transportation.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски