Product Introduction

The intercooler is actually a supporting part of the turbocharger, its role is to improve the engine's ventilation efficiency. One of the reasons why a turbocharged engine has greater power than a normal engine is that its ventilation efficiency is higher than the natural intake of a normal engine. When the air enters the turbocharger, its temperature will increase significantly and its density will decrease accordingly. The intercooler plays the role of cooling the air. The high-temperature air is cooled by the intercooler before entering the engine.

Whether it is high-temperature compressed air or air that has undergone heat transfer through the intercooler, it must first pass through the end tank to enter or leave the intercooler. Therefore, the shape of the end tank directly affects the airflow rate, while the material determines its ability to withstand pressure.

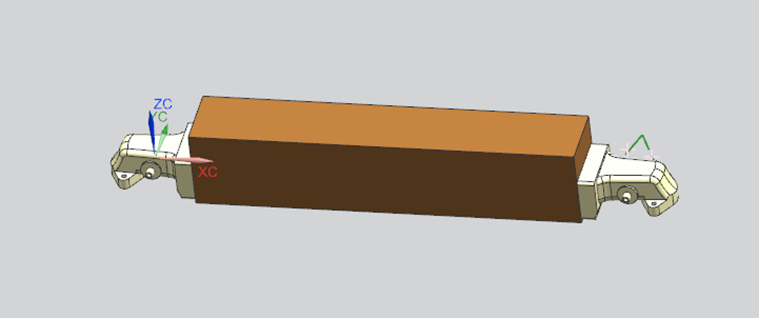

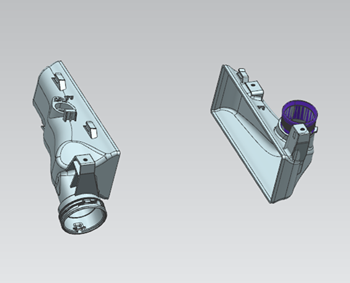

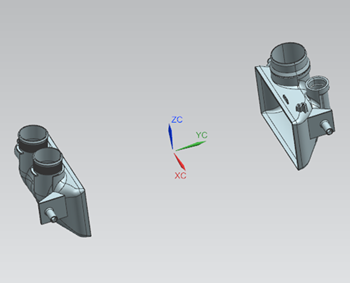

Here is the end tanks assembling diagram:

Material and process

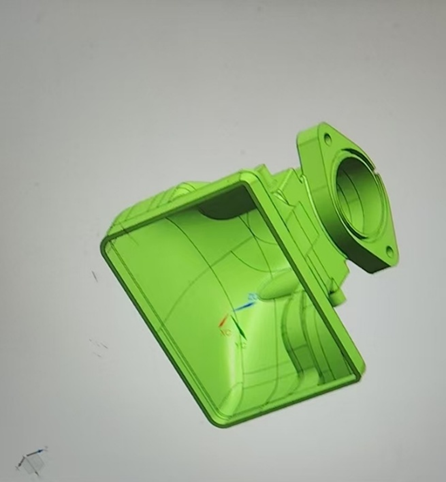

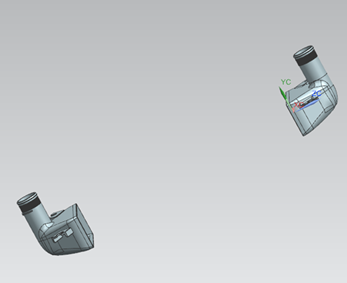

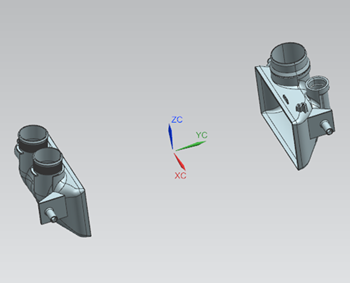

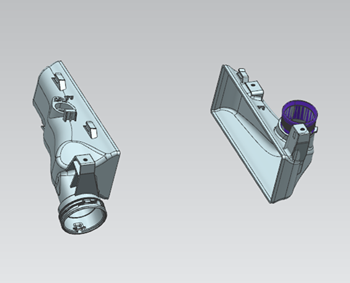

UG is used to create the drawing and adjust some details to make it suitable for machining.

Then program it on the CNC. 3, 4, 5 axis machining centers are used for coordinated machining after the drawing is confirmed.

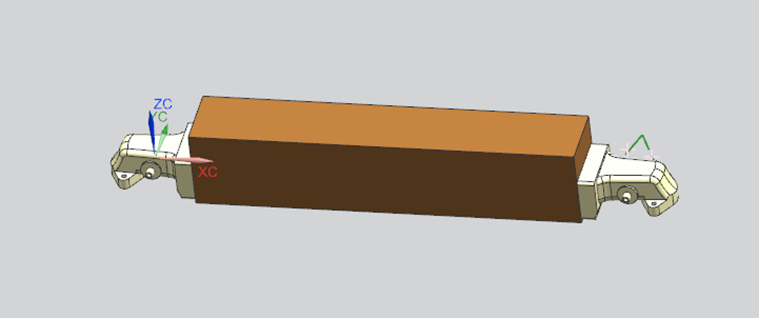

The material is 6061-T6 aluminum alloy billet, here is the picture of the material which is with location holes, can be processed directly on the machine center:

Then they are fixed on the 4-axis machine, processed the outer shape first:

There is a video of the machining the outer shape:

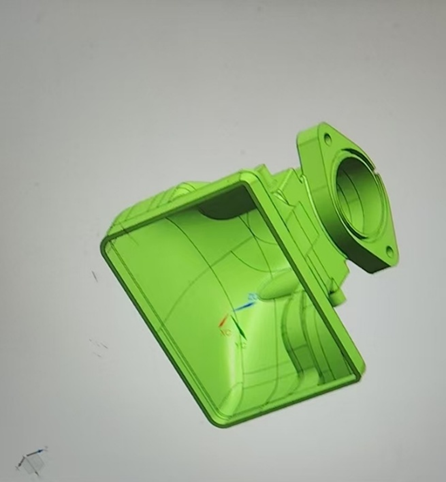

After the outer shape is finished, the 5-axis machine center is used to milling the inner surface.

Below is a short video showing the process:

1 pc of the intercooler end tank takes about 15-16 hours.

Below is the finished products:

The details of the tank:

Packing

After machining they are sent for cleaning, inspection and packing.

For this end tanks, we inspect the surface and the dimension carefully before packing to ensure there are no scratches or dents on the surface and the dimensions meet the tolerance requirements.

Each end tank is individually wrapped and protected with foam bag, placed into a carton, and the carton is further packaged in a wooden case for outer protection.

Here is the sencond random inspection video:

Conclusion

Our customers are very satisfied with our products and services, then we have developed sevel types of this parts.

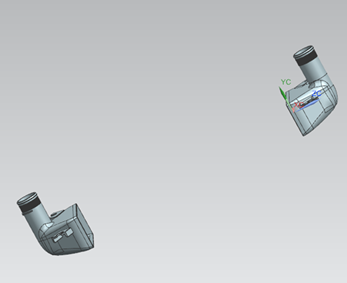

We are currently very proficient in this type of product. Below are some other style tanks:

other type end tanks 1

other type end tanks 2

other type end tanks 2

other type end tanks 3

Ningbo Joyo Metal Products Co.,Ltd. now has highly mature skill for manufacturing this type of aluminum parts, we are enable to achieve a tolerance of ±0.05mm. Both our product quality and services have been recognized by numerous customers. If you have any requirements, send an inquiry now!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски