Product Introduction

This is a 304 stainless steel wire clip, using a spring machine for its formation allows for precise shaping of the wire according to specific design requirements. The wire diameter is neither circle nor ellipse. It is custom-made and precisely drawn material.

Material and process

Material Introduction

This clip is made from 304 stainless steel by wire forming. It is designed to meet the unique specifications of a particular client or automotive application. The customer send their exact needs, such as the clip's size, shape, load - bearing capacity, and the specific location and function. For example, different models may require T-body clips of varying lengths or with different angles to fit precisely into their body structures.

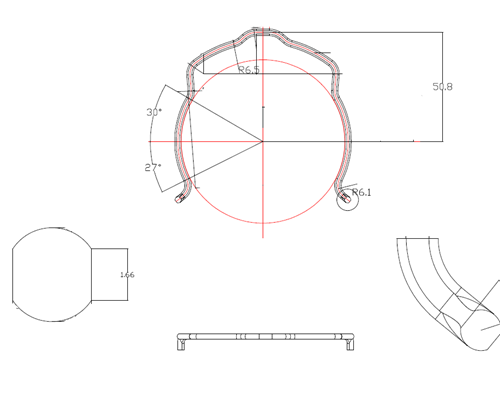

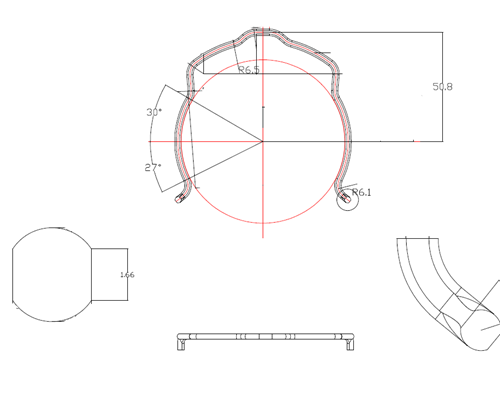

Drawings analysis

Here is the clip sketch:

Manufacturing process

The difficulty of this project lies in the fact that we need to customize the wire material that meets the specifications according to the drawings provided by the customer. This kind of wire material is neither a standard cylindrical shape nor an elliptical shape. Here is the shaped material:

Shape the wire into such a special cross-section demands extremely high precision in engineering calculations. Also, during the production process, controlling the stress distribution of the wire to ensure its mechanical properties meet the standards while achieving the non-standard shape is quite challenging. The spring machine is a good choice to form the wire material.

The wire is fed through a rotating mandrel while forming rolls apply pressure to create coils with precise pitch and diameter. Wire is bent around a mandrel and twisted to form clip at specific angles. It requires custom tooling and multi-axis coordination to form irregular cross-sections.

Product show

Here is the finished T-body clip:

Packing

Before packaging these T-body clips, we inspected their critical dimensions. The qualified ones were packaged, they are packed into cartons, which are then palletized. Palletizing the cartons with secure strapping ensures stable stacking during transportation, reducing shifting and damage in transit. This attention to detail in both inspection and packaging guarantees the clips arrive in optimal condition, ready for assembly or further processing.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски