Product Introduction

This custom manufacturing project is from our Brazilian client. It is a knob on the seat recliner of a vintage car, which is casted in once from bakelite material. Based on the samples sent by the customer, we replicated the same knobs as before.

Material and process

Material introduction

Bakelite has a high hardness, is resistant to scratches and wear, and is not prone to deformation even after frequent rotation and adjustment. It can still maintain its appearance after long-term use. It can operate stably in an environment ranging from 120 to 150℃, and can withstand direct sunlight and equipment heat inside the cars.

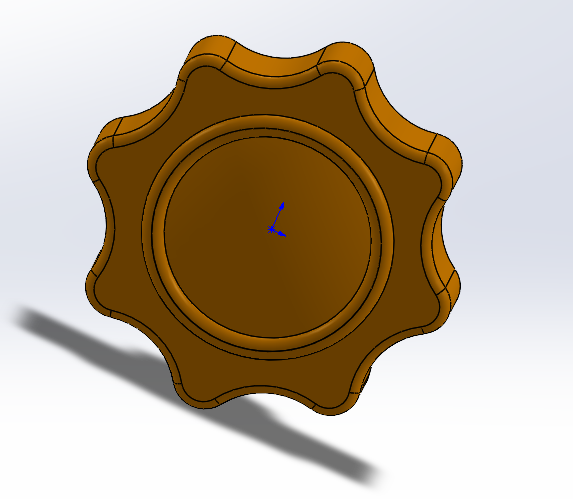

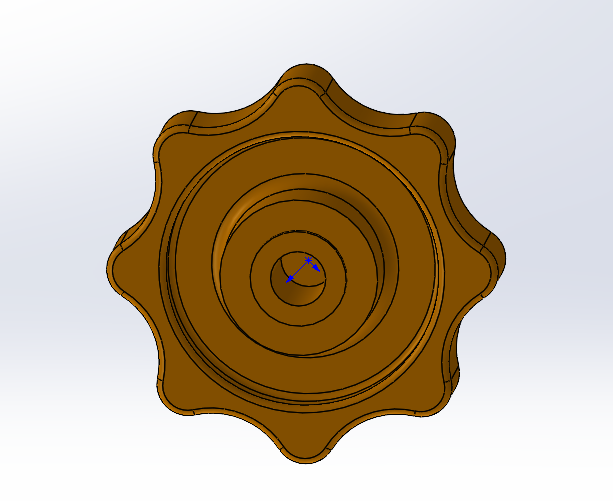

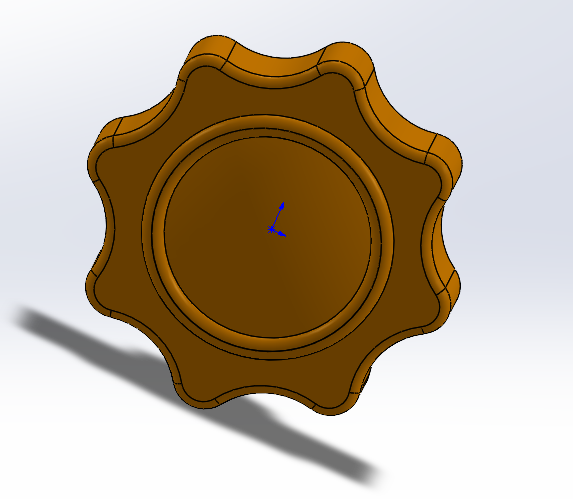

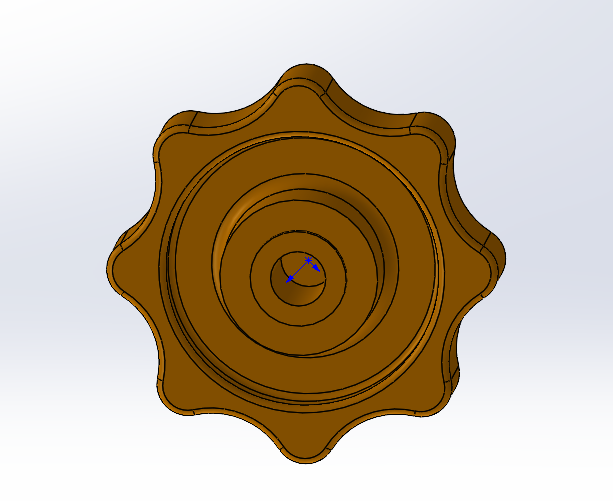

Drawing Analysis

Here are the 3D drawings of the recliner knob:

The knob structure is simple, the mold is quite easy to design and make, just the screw does require some effort. There are no screws on the market with exactly the same specifications, so they need to be custom-made.

Mold Making

After the drawing confirmed, we move on to make the mold. The process is same as the mold of die casting zamak product. Here are the pictures of the mold:

Belowing is the rought casting with inserted the steel screw:

After that, the knobs are sent for polishing , then get the finished knob:

Conclusion

Ningbo Joyo Metal Product Co.,Ltd. is specialized not only in metal components but also offer a wide range of plastic parts. Equipped with proficiency in multiple manufacturing processes, we are well-positioned to meet diverse custom requirements from clients across industries.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски