These are expansion tanks made of aluminum and milled by a 5-axis CNC machine tool.

It was directly processed by a 5-axis machining center. Unlike traditional 3-axis machining, which operates along three linear axis, 5-axis milling adds two rotational axes, enabling the cutting tool to approach the workpiece from virtually any angle.

Material and process

Material advantage

These expansion tanks are made from aluminum alloy. Aluminum's low density reduces overall system weight, an important consideration in automotive applications. Additionally, aluminum's thermal conductivity helps dissipate heat from the fluid, preventing overheating, while its resistance to rust and chemical degradation ensures longevity.

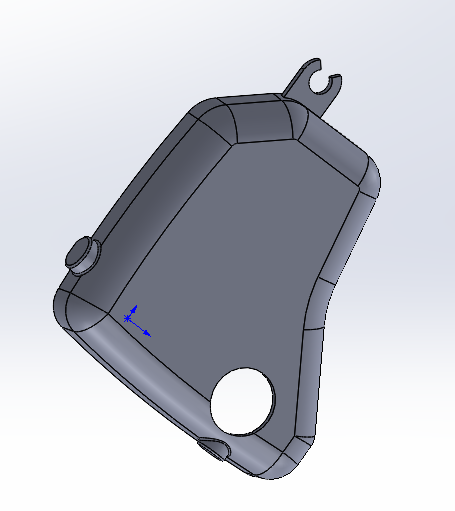

Drawings analysis

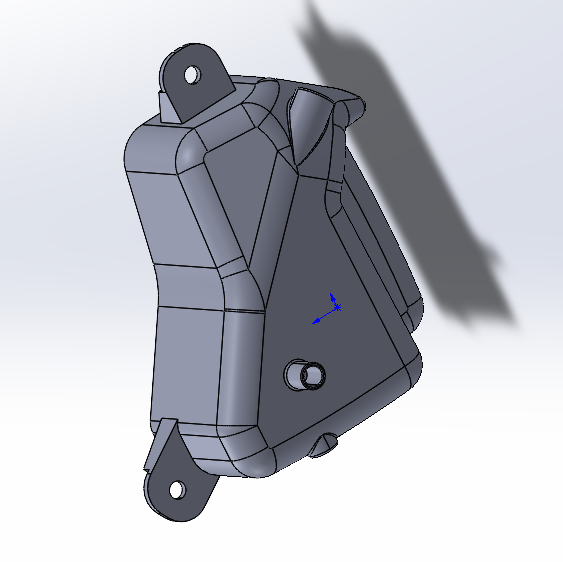

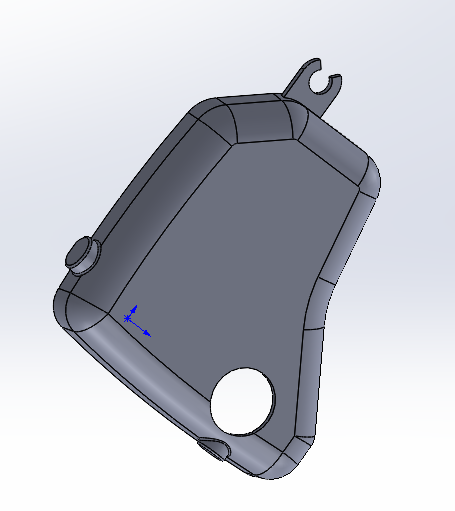

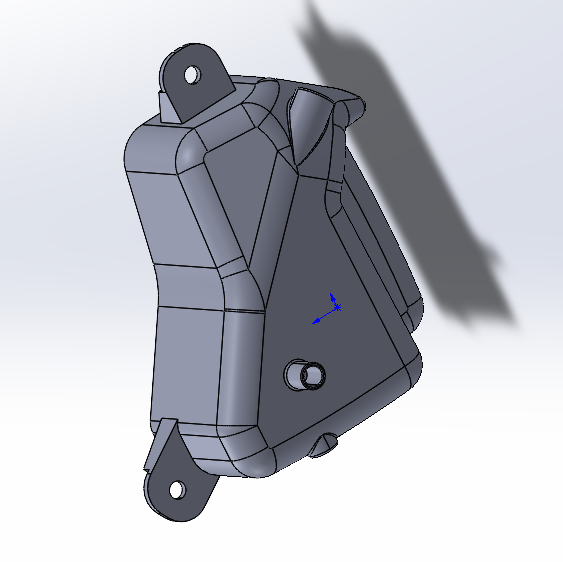

Below are the tanks' 3D drawings:

The expansion tanks are milled by 5-axis machine with machining surface. This multi-axis machine enables the cutting tool to work from virtually any angle with high precision and efficiency. A key benefit is it can complete complex machining operations in a single setup. This not only enhances dimensional precision but also decrease setup time.

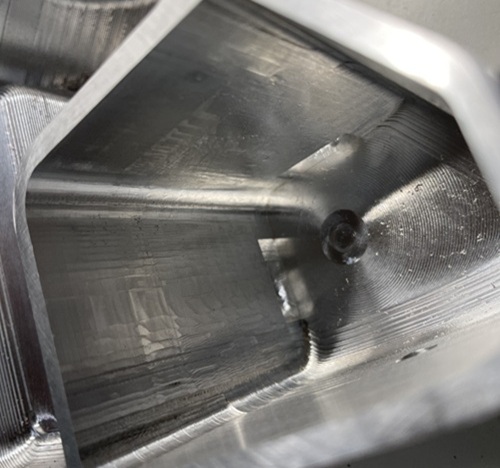

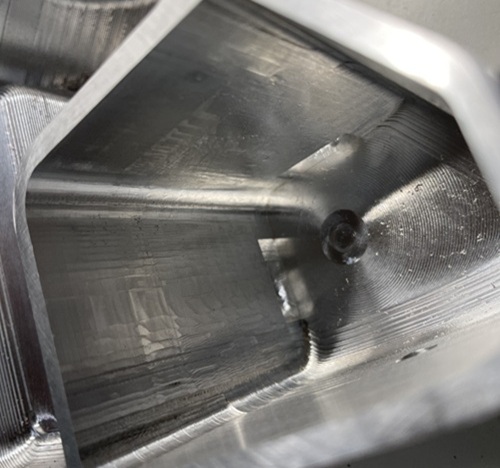

Products Show

Below are the finished products:

The cost of five-axis machining machines is relatively high, the customers pursue cost-effectiveness and have no strict requirements for the surface. To reduce the cost, the lines are relatively thick and the machining marks are obvious. Here are the expansion tank project gallery:

the expansion tank backview-1

the expansion tank backview-2

the expansion tank backview-3

the expansion tank backview-4

the expansion tankcover backview-1

the expansion tank,cover backview-2

Conclusion

Ningbo Joyo Metal Part Co.,Ltd. is specializes in providing tailor-made services for our clients. Every project is approached with a focus on understanding your unique needs. Whether it's customizing the material, refining complex geometries through advanced processes such as 5-axis CNC machining, or adapting designs to meet strict industry standards.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски