Product Introduction

This part is a flowmeter housing used in the automotive industry. The automotive air flow meter is an important sensor of the car engine. Its core function is to detect the air intake of the engine and convert it into an electrical signal to transmit to the Engine Control Unit. Based on this signal, the ECU accurately controls the fuel injection quantity, enabling the air and fuel to be mixed in an optimal ratio. This ensures efficient combustion of the engine, stable power output, and can also optimize fuel economy and reduce exhaust pollutant emissions.

Material and process

Material and 3D drawings analysis

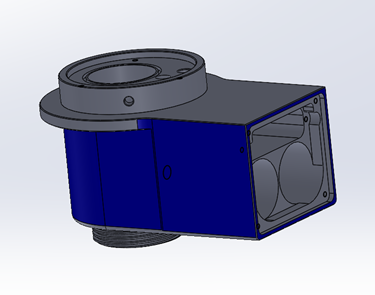

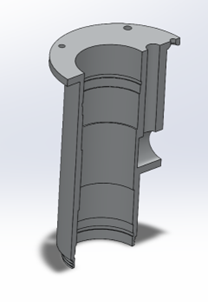

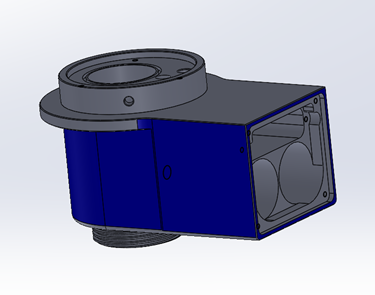

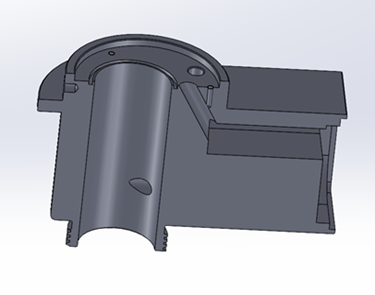

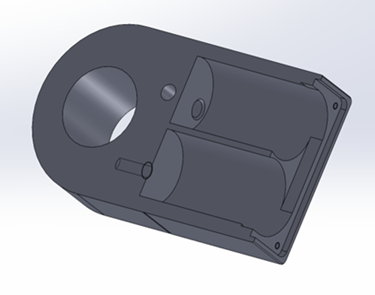

The parts are made from aluminum alloy. There are several parts for this protokomer assembly, include body,adapter, cover and so on.

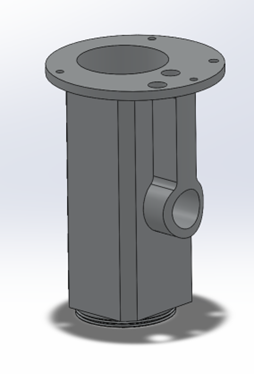

3D drawings-1

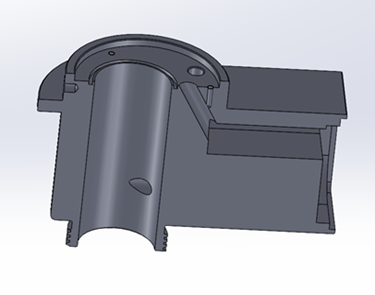

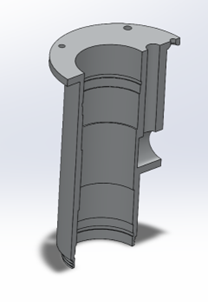

3D drawings-2

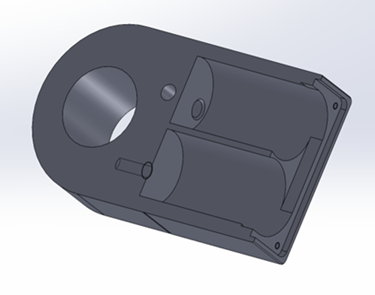

3D drawings-3

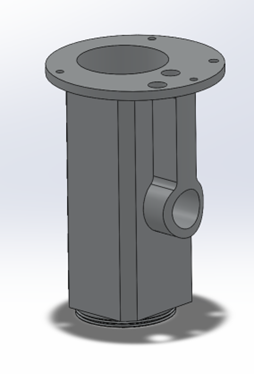

For the protokomer, below are the 3D drawings:

Manufacturing process

The housing are worked directly by aluminum billet, use 4 axis CNC machine. The hole is pretty deep, and hard to work. We use special deep hole drill machine to meet customer's requirement.

Regarding its structure, we hot forged the aluminum rod by hot press die, then heat treatment – anneal to make soft , and CNC milling and turning by programming. It is eccenter for the main holes.

Parts assembly

Apart from this, there are still has a ring to assembly and the ring need to make thread.

Packing

For flowmeter components, each part is individually wrapped with bubble wrap to safeguard the surface finish.

Then put them in cartons and laid on pallet, wrapped with protective film to avoid them scattering.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски