Production Introduction

Several kinds of aluminum casted elbow or pipe, used in automotive exhaust system to connect with other pipes. With different type of cars, so there are many types of casted elbows.

Design and drawing comfirmed

First, analyze the drawings to determine the pouring port and the mold closing position. For areas where the wall thickness does not reach 5mm needs to be increased. A margin also needs to be left at the processing position. Confirm the shape of the mold, and then determine the structure of the sand core and the mold.

Material and Process

The material is A356 aluminum alloy, and final requires T6 heat treatment.

First of all, a sand core needs to be made: Inject sand into the sand core mold. Open the mold, and you will get the sand core.

tooling for sand core

divide the sand core tooling to take off

sand core part for aluminum casting

Then place the sand core on the casting mold of the product. At around 500°C, the aluminum ingot melts and is cast into shape, results in the rough castings.

rough aluminum gravit casting part

rough aluminum permanent casting part

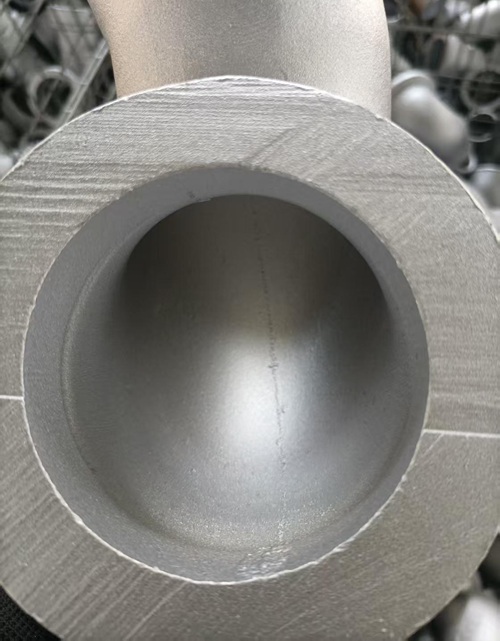

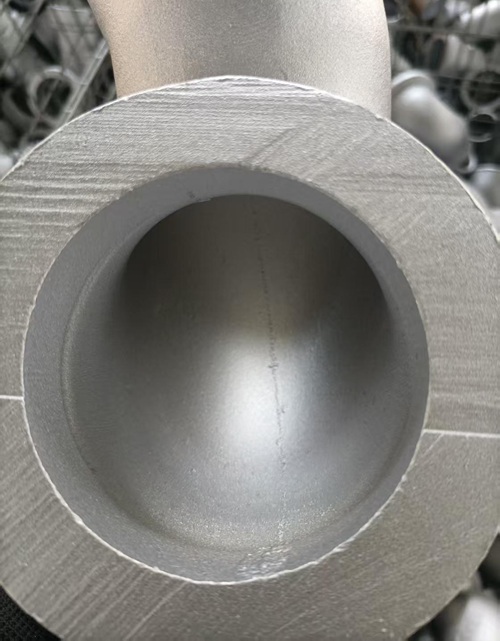

After the rough casting finished, the sand core needs to be crushed and cleaned up. Then you will get the aluminum castings. At this point, the aluminum castings has many burrs and pouring gates that need to be cut and ground off.

After grinding, all the products should be packed up in bulk, going to T6 heat treatment.

Then go for shot blasting treatment. The surface of the product will be nice and the color uniform after shot blasting.

Then the product inspection begins. The weight, inner wall and outer surface all need to be checked. Unqualified products need to be picked out and then reworked. Packed qualified products in plastic bags and sent to process.

The end face of this product needs to be machined, and a sealing groove needs to be processed as well. CNC turning and CNC milling processes will be used.

The processed products need to be checked again. Those without any problems will be packed up.

Each product is packed in bubble bags to prevent bumps and scratches, then pack them into wooden box ship to customer.

Ningbo Joyo Metal Parts Co,. Ltd. has the ability to integrate multiple processes for manufacturing parts and packing.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски