Production Introduction

This project is from our Brazil customer. These custom zamak parts perfectly meet the needs of classic car enthusiasts and restoration workshops, combining authentic vintage styling with modern manufacturing durability to revive the charm of classic vehicles while ensuring long-term reliable use.

Material and process

Material adavantages

Zamak accurately reproduces original handle geometries with tolerances of ±0.05mm, matching the vintage design details of classic models, e.g., mid-20th century Brazilian-made Volkswagens. And zamak die casting can realize lower tooling costs for small-batch production compared to aluminum or steel casting.

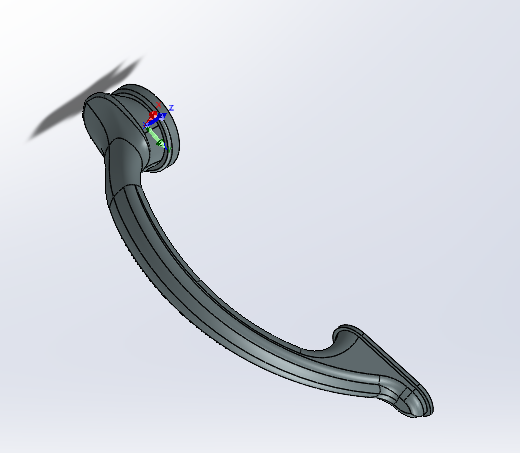

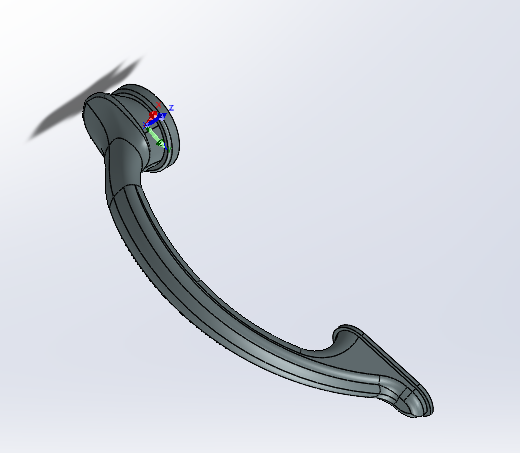

Drawings analysis

These are the 3D drawings of the handles and door striker plate, they are designed according to the samples sent from our customer. After the drawings were confirmed by the client, we began to manufacture the molds.

Making mold

The molds are made from H13 material and cut into blanks by sawing. Then using milling machines, lathes, and other equipment, the blanks are machined to near the finished product dimensions. Key parts such as the core and cavity are quenched and tempered to improve hardness and wear resistance. After that, CNC machining complex curved surface, wire EDM machining precision holes and grooves. Using electrodes to machine the fine structure of the cavity and core as well. Finally, surface grinding, cylindrical grinding, etc., to ensure the flatness and perpendicularity of the parts. The cavity is treated with nitriding, carburizing to enhance surface hardness and anti-sticking properties. Here are the pictures of finished molds:

Mass production

After the samples get approved, the mass production begin to be produced. Here is the rough castings:

Surface finish

These handles are sent for polishing and chroming after the castings are cutting off from the trees. Here is the picture of the polishing and chroming handles:

The chromed surfaces of these products have very high requirements. Initially, we didn't fully understand the customers' needs, and the first sample don't get approved. Then we raise the surface requirements until there were no flaws on the visual surface.

Packing

The surface of this batch of goods needed to be well protected, so each item was individually packaged in a bubble wrap bag, each product was labeled, and finally packed in a sturdy cardboard box.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски