Production Introduction

This deckel is made from 1.4571 stainless steel by CNC turning and drilling the holes. It deliver the perfect balance of durability, precision, and adaptability, making them indispensable in sectors where performance under stress is paramount.

Material and process

Material advantage

The deckel is made from 1.4571 stainless steel rod, also known as 316Ti material. It's a martensitic-austenitic alloy celebrated for its exceptional corrosion resistance, high tensile strength which is up to 650 MPa, and stability at elevated temperatures. These properties make it ideal for parts exposed to harsh environments, where resistance to rust, and oxidation is non-negotiable. Below picture is the 1.4571 stainless steel rod with black surface:

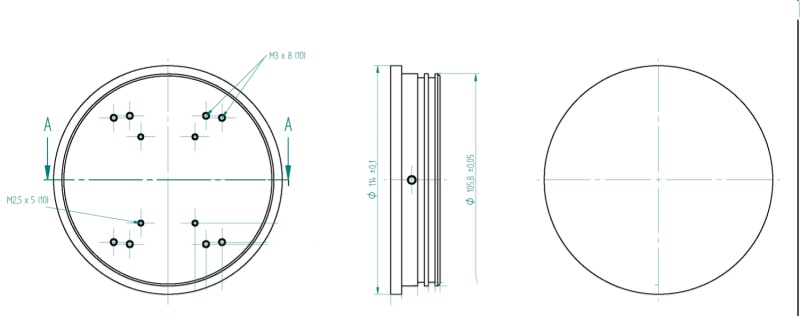

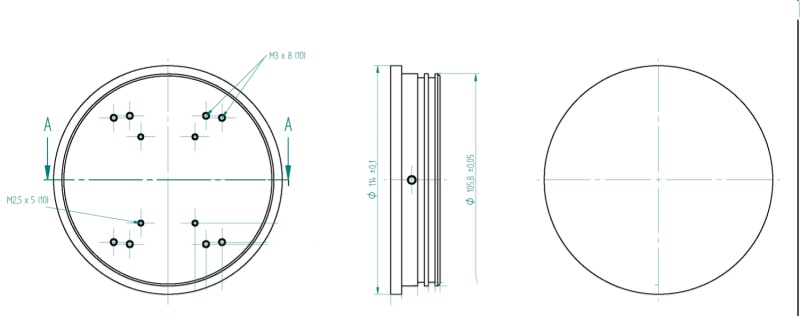

Drawing analysis

Here is the deckel drawing:

Machining Process

It is made of bar stock with an outer diameter of 120mm, the sawing machine cuts the material into pieces.

After cutting into pieces, CNC machining is used to turn the outer circle.

The most challenging aspect of this manufacturing process lies in machining many small holes and threads, with the M2.5 threading operation standing out as an especially hard task. These tiny features demand extraordinary precision: the holes themselves are often just 2–3mm in diameter, requiring drill bits and taps that are slender, fragile, and highly easy to deflection under even minimal pressure. For M2.5 threads, the tap's cutting edges are razor-thin, struggling to withstand the intense friction and torque generated when cutting into tough materials like stainless steel or alloyed metals. Imported tap are used, the workers have to be very careful to strike the threads well.

There are several factors like chip evacuation: in such small holes, metal chips have little space to escape, often block the tap's flutes and causing it to bind. This binding, in turn, leads to sudden torque spikes that snap the tap outright, has resulted in numerous broken tools during production. Each broken tap risks damaging the workpiece: fragments can get wedged deep within the threaded hole, scoring the already delicate threads or even warping the surrounding material, threatening to render the entire part scrap.

To address this critical issue, we turned to electrical pulse machining , a specialized technique that save the damaged workpieces without compromising their integrity. EPM works by using high-frequency electrical discharges to erode the broken tap fragments: a precision electrode, shaped to match the hole's dimensions, is positioned near the broken tap, and controlled sparks between the electrode and the metal fragment vaporize small particles of the tap, gradually dissolving it away. This process is non-contact and generates minimal heat, ensuring the workpiece's base material, including the partially formed M2.5 threads remains unharmed.

Below are finished deckel:

Packing

Before packaging, we conduct careful thread inspections using plug gauges to ensure each threaded component meets precise dimensional standards.

Once the threads pass inspection, the parts are packed into sturdy wooden crates. These crates are constructed from high-quality composite board, minimizing the risk of scratches, dents, or thread damage during handling.

Ningbo Joyo Metal Products Co.,Ltd. is bold in challenging and relentless in pursuing breakthroughs. This spirit is woven into every stage of our work, whether it's tackling intricate machining tasks that others shy away from, such as drilling micro-sized holes in high-hardness alloys or perfecting ultra-precise threads that push the limits of tolerance, or exploring innovative techniques to overcome production bottlenecks.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски