Product Introduction

This is an aluminum part, named middrive spider and made by CNC machining. It's used in bicycle industry. The customed middrive spider is designed with high complexity. Engineers can change the exact dimensions such as the diameter of the spider's hub, the length and thickness of its arms, and the size.

Below is the middrive spider assembly:

Material and process

This middrive spider is made from aluminum 6061-T6 material by CNC machining process. Aluminum alloys are suitable for CNC machining. They have low hardness compared to some other metals like steel, which means that cutting tools can move through the material more easily during the machining process.

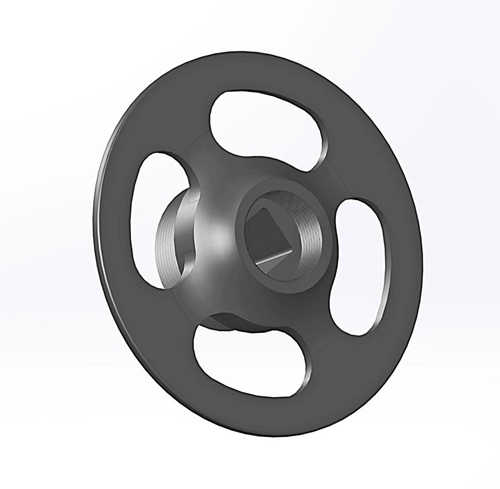

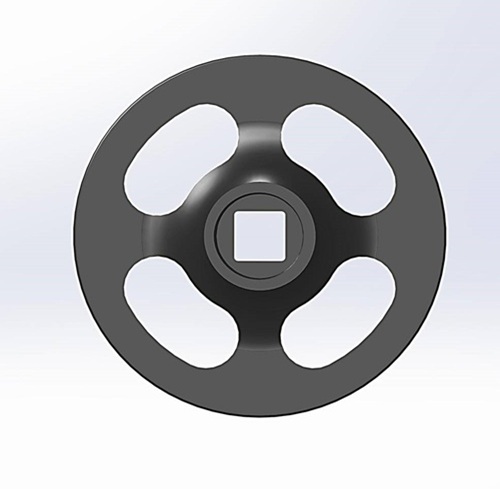

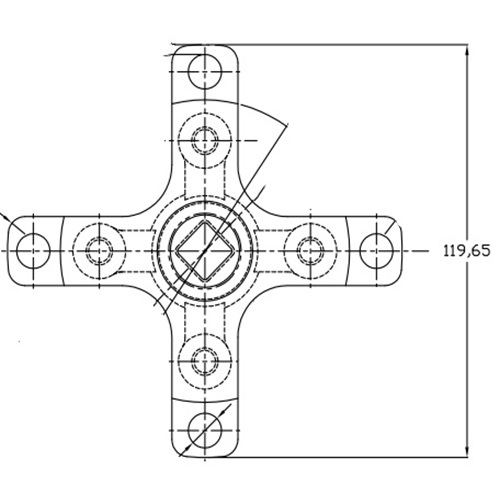

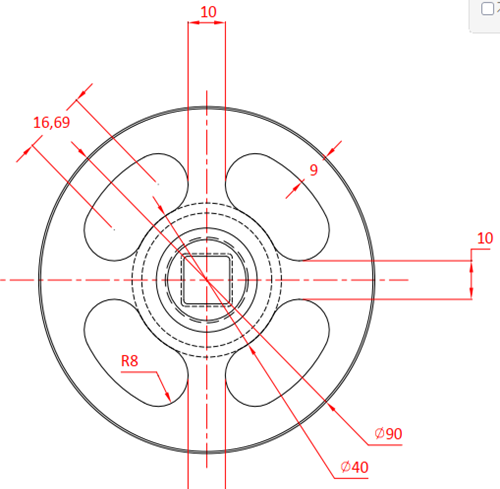

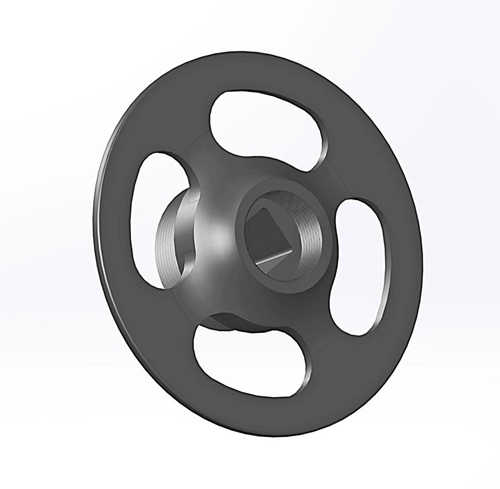

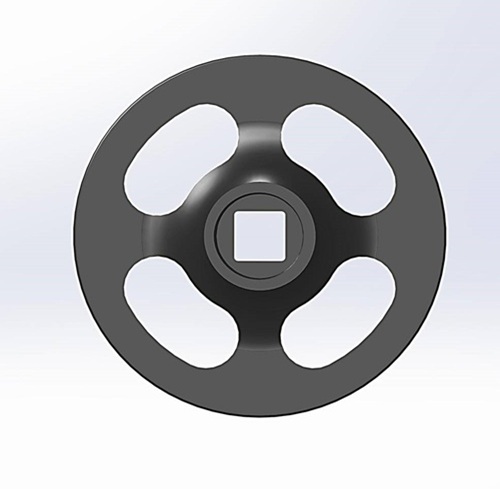

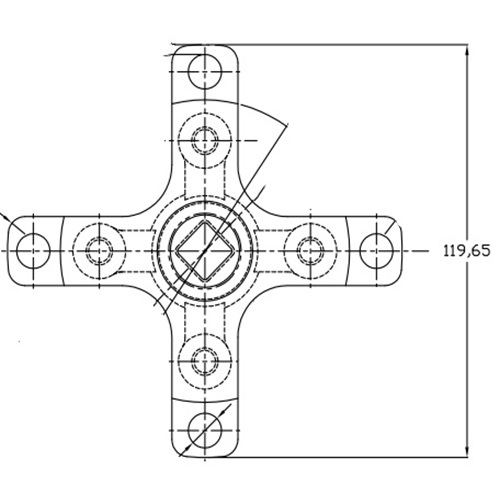

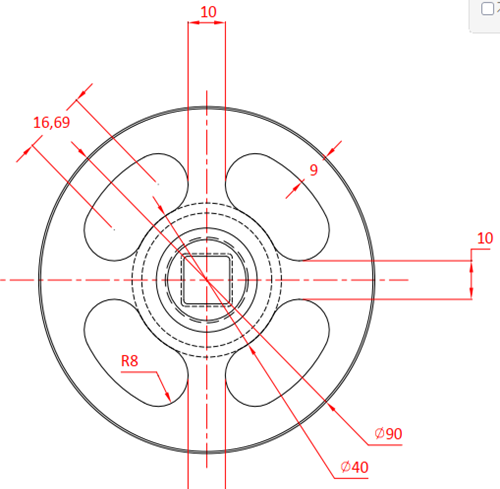

There are 2 kinds of the middrive spider, one is round, another is the cross-shaped. Here is the middrive spider sketch and 3D drawings:

middrive spider 3D drawings -1

middrive spider 3D drawings -2

middrive spider sketch-1

middrive spider sketch-2

All processing is carried out by CNC turning and CNC milling. The most challenging aspect lies in machining the square, a tapered profile at its center. Unlike a standard square through - hole, which can be directly milled using conventional methods, this particular geometry need special plans.

We first use a milling machine to mill a square through hole, and then punch a taper. After machining, the parts undergoes surface finish. Surface sandblasting, matt processing, black anodizing, laser marking.

This machining methods not only solves the taper but also ensures the dimensional accuracy.

Here is a video, which is introduces the middrive spider:

Packing

This product has extremely high surface requirements, so we take extra step during packaging to prevent any damage. Each unit is first wrapped individually in a bubble bag, this layer of cushioning acts as a protective barrier, absorbing shocks and preventing scratches.

After being sealed in bubble bags, the products are carefully placed into sturdy cardboard boxes. Once the boxes are filled and sealed, they are loaded onto plastic pallets. To ensure stability during transportation, we secure the boxes to the pallets using strap. The entire pallet is wrapped in multiple layers of stretch plastic film.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски