Product Introduction

This project is from a client we previously reached out but didn't end up working with. This time, though, the project has given us the chance to collaborate. It's a beryllium copper pin, CuBe2, and it's really small in size with tight tolerance. The pin is made by Swiss type turning machine. Here is the picture of the finished CuBe2 pin:

Material and process

Material Introduction

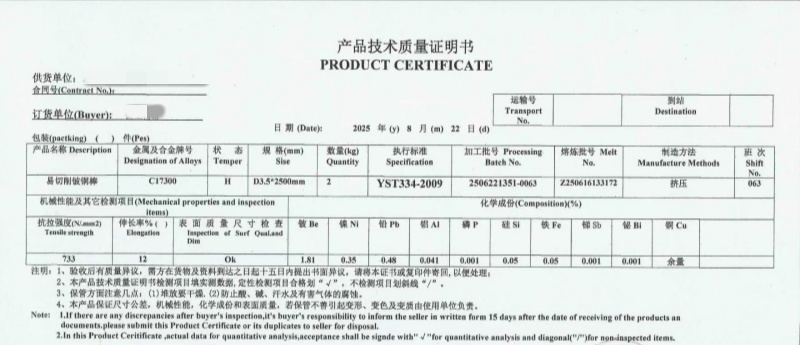

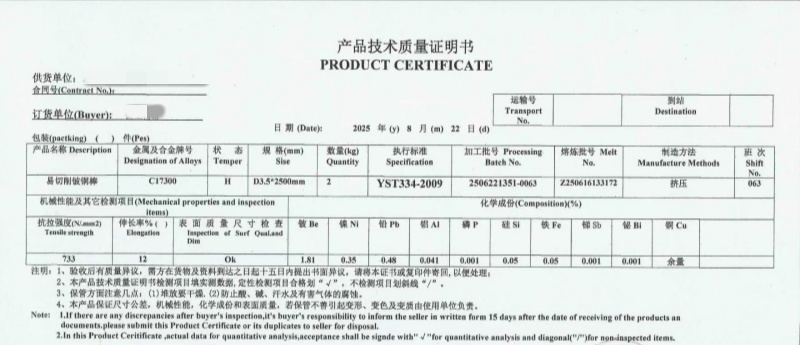

This custom CuBe2 pin is made from a kind of beryllium copper alloy material. It is a widely used copper-based alloy, and can be easily machined in the soft state (before aging), and can also be stamped, bent, or welded. Its tensile strength can reach 1100-1400 MPa after heat treatment, and hardness up to 38-44 HRC, much stronger than ordinary copper alloys. Below is the picture of the material certificate:

Drawings Analysis

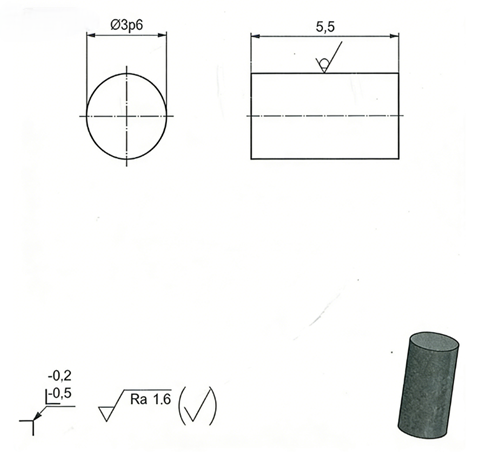

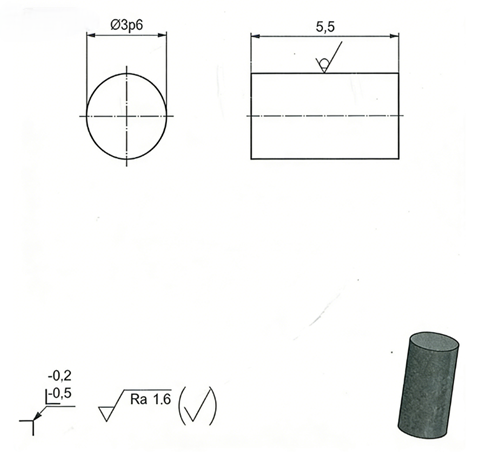

This is the drawings of the custom CNC machining pin:

There are only 2 key dimensions and one tolerance requirement, the φ3p6 dimension is 3.006-3.012mm. The quantity of the order from the customer is small, the product requirements are high, and the material price is expensive. Therefore, very few factories are willing to work it. This is precisely our opportunity. We are good at small-batch metal parts customization, with extensive experience in different materials and processes.

Manufacturing process

After analizing the drawings, we begin to start to buy the material. The rod on the left in the picture is the raw material for this product:

This custom CuBe2 pin is machined by the Swiss type turning machine, which has excellent machining precision, especially suitable for small and ultra-small precision parts with high dimensional accuracy requirements. And it is perfect for processing slender shaft parts, effectively avoid workpiece deformation and vibration during machining, ensure stable quality.

Passivation treatment

Copper alloys are easy to oxidation when exposed to air, which will form black or green oxide on the surface and affect the appearance and application. Passivation forms a dense protective film on the surface of the machining pins, which can effectively improve corrosion resistance and prevent rusting, extending the service life of the parts. Here is the finished parts:

Inspection

The goods need to be inspected carefully before shipment. The common caliper and digit readout micrometer can't measure the tolerance, so a new digimatic micrometer is used to inspect this custom tiny pin.

Packing

These finished custom CuBe2 pins are packed in a bag and put into a box, sent by express.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски