Product Introduction

There are 2 parts, a motor housing and a venturi, they are both used in a sewing machining. They are made from aluminum alloy by CNC turining process. The motor housing, machined from lightweight but durable aluminum alloys, serves as the protective casing for the sewing machine's drive motor. The venturi, a airflow regulator, which relies on CNC turning to achieve its specialized geometry.

Material and Process

These 2 parts are made from aluminum material. Its lightweight reduces overall machine weight, corrosion-resistant to withstand lint, oil, and occasional fabric dyes, and thermally conductive to dissipate motor heat. The CNC turning process, with its computer-controlled precision, ensures each part meets the exact dimensions required for seamless integration, making them indispensable to the sewing machine's efficiency and durability.

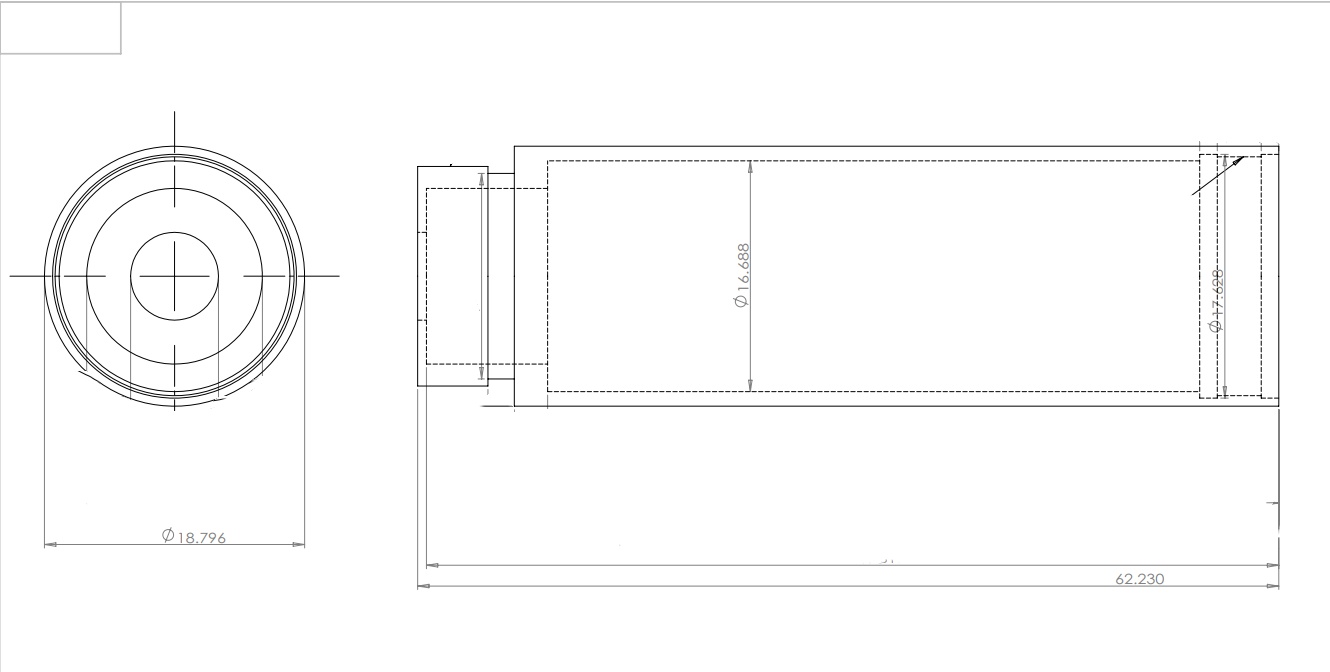

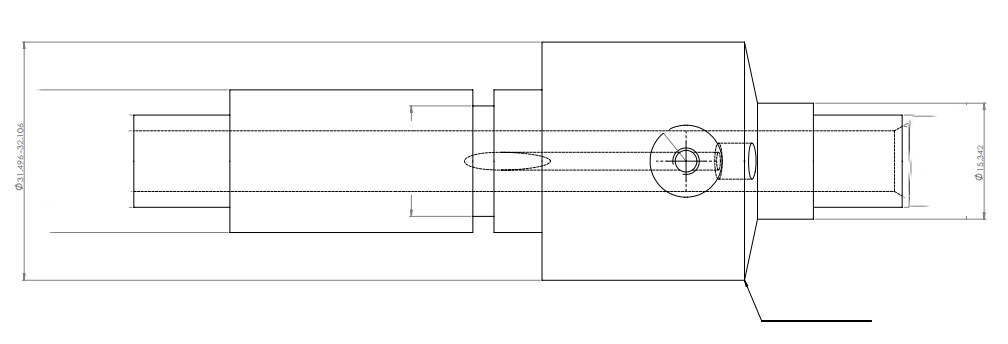

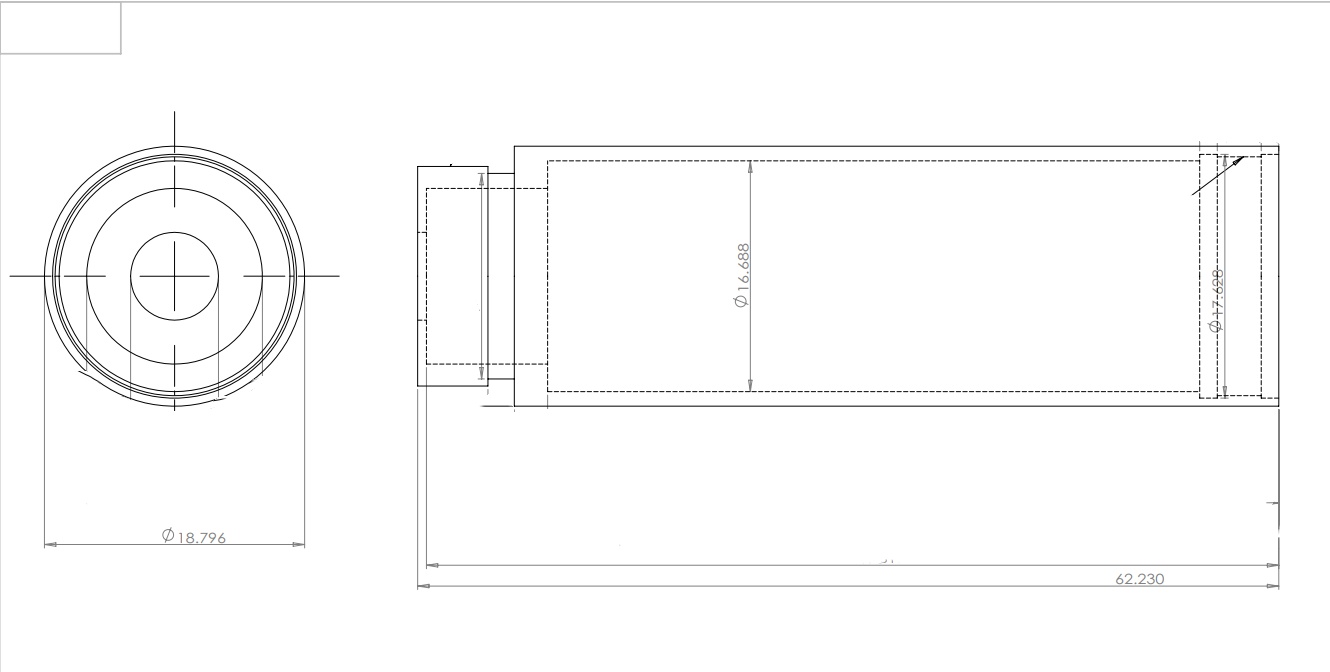

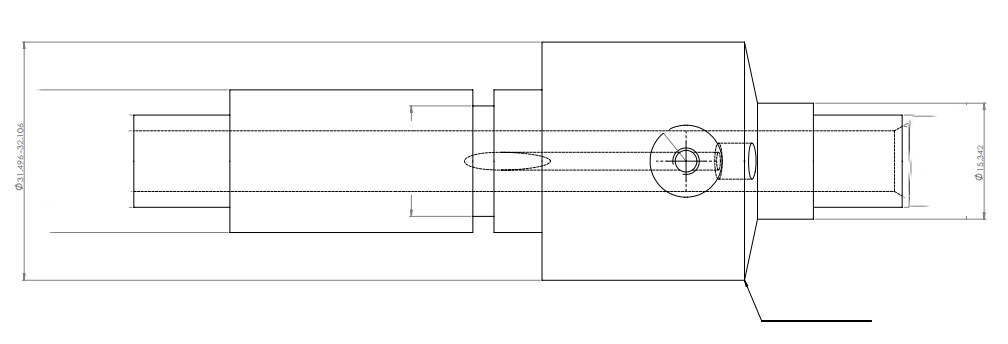

Here is the drawings:

They are both made by CNC turning process. The motor housing is made from a solid rod. CNC turning precisely shapes the motor housing inner bore to accommodate the motor's rotor and stator with tight tolerances. Its outer profile, often has integrated mounting flanges and threaded holes, is also CNC-turned to align seamlessly with the machine's frame, preventing misalignment that could cause noise or premature wear.

For the motor housing, difficulty lies in the blind holes, with deep holes and thin walls. This product requires solid rods to be made. The thread is a left-hand thread.

motor housing after turning 1

motor housing after turning 2

motor housing after turning 3

For the venturi, the central hole is very long. It is necessary to drill holes at both ends to the middle seam. In addition, is also needs to process the small inclined holes. CNC turning ensures the venturi's smooth internal surfaces minimize air turbulence, guaranteeing consistent suction power.

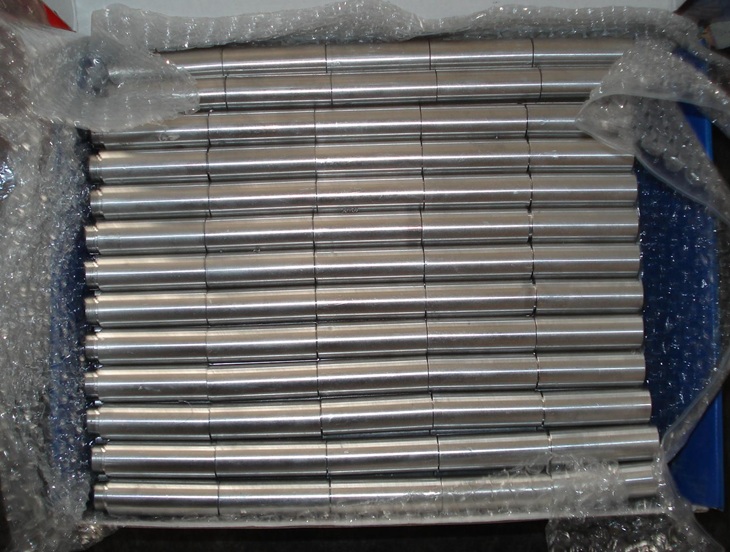

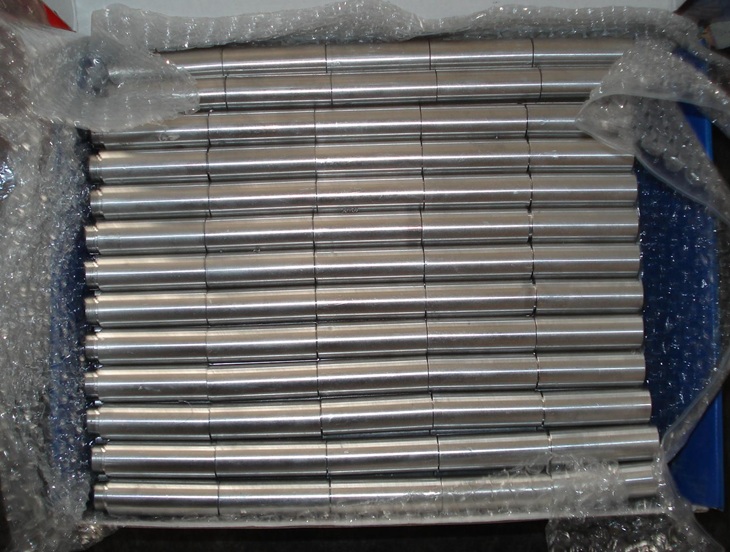

Here are the worked mass production sent for anodizing:

The motor housings need to be black anodized and the venturis need to be golden anodized.

Here is the introduction of the housing and venturi:

Packing

Before packing, we inspect the product carefully. Here are our tools for inspection, gague is used to checking the thread:

The ziplock bags are used to pack the venturi and ordered arrangement in carton. The motor housings are arranged neatly and placed in the box.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски