Product Introduction

This is a stainless steel gripper bar fully made by CNC machining, and it's a custom project from our UK client. The main challenge in manufacturing this gripper bar lies in the through hole. We had to ensure its dimensional accuracy and smooth inner surface during machining. As for the material, the stainless steel gives the gripper bar excellent durability and strong corrosion resistance, making it perfect for long-term use.

Material and process

Material Introduction

The material is 304 stainless steel, it's common in customizing metal parts. It has high tensile strength and toughness. Even after long-term friction, it maintains structural stability, reducing the need for part replacement and lowering maintenance costs.

Drawing analysis

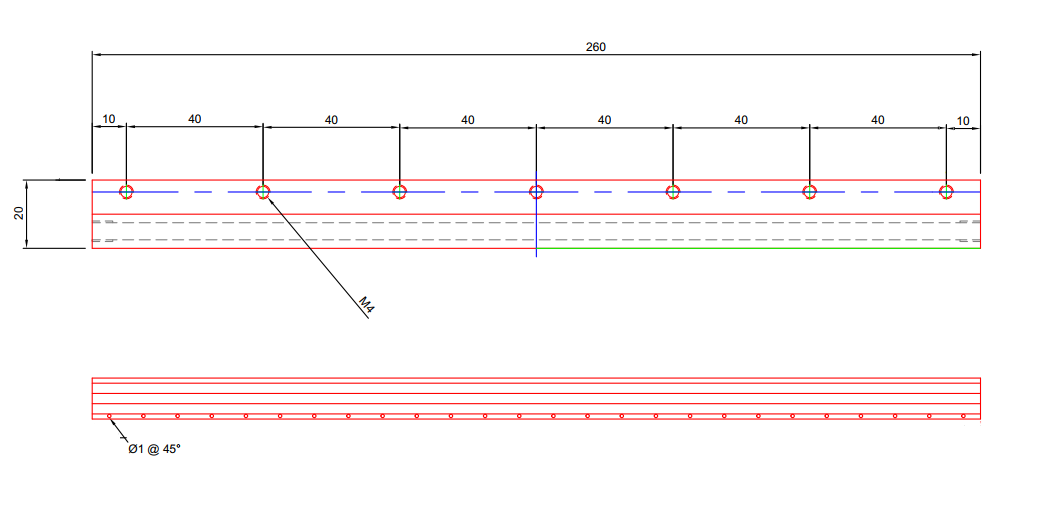

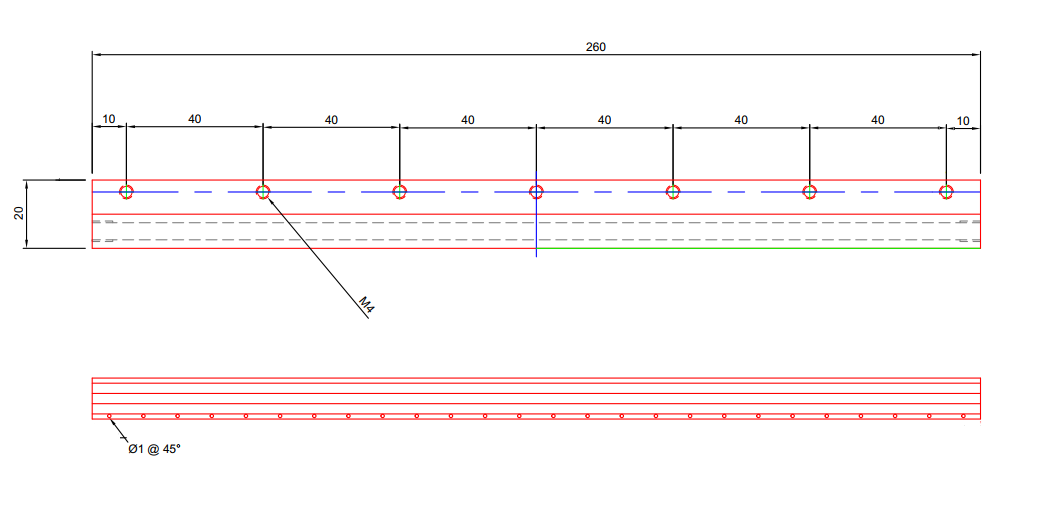

Here is the drawing of the custom gripper bar:

The biggest challenge lies in the through-hole marked by the blue line. It is easy to getting off course when drilled from one end, so we decided to start drilling from both ends and converge in the middle. However, a step is inevitable at the connection point. Then those small holes with a diameter of 1mm that are easy to cause the tap to break inside the hole during drilling.

Manufacturing Process

This gripper bar is machined directly from the square rod material, here is the picture of machining:

The belowing is finished gripper bar:

Inspection

Before the parts sending to the customer, we conduct a carefully inspection of the gripper bar. The small holes on the surface are inspected using a plug gauge. Common dimensions are measured using a caliper. The goods can be shipped only after the dimensions have been confirmed to meet the requirements.

Packing

This order is not very large. We wrapped it with bubble fim and then placed it in a box, and sent it to the customer by courier.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски