Product Introduction

Our customer wants a set of hinges, which should be light, hard and strong at the same time. Let's recommend the materials. After our mutual discussion, 7075 aluminum alloy has become the best choice for everyone.

Material and Process

This hinge is made from 7075 material by CNC milling process. 7075 aluminum alloy is a typical representative of the 7 series aluminum alloy. With the precise ratio of zinc, magnesium, copper and chromium, it can achieve a tensile strength of ≥572MPa and a yield strength of ≥503MPa in the T6 heat treatment state, while maintaining the lightweight advantage of 2.81g/cm³. It also has good precision machinability, is suitable for CNC turning, milling and other processes, and has controllable stress corrosion resistance.

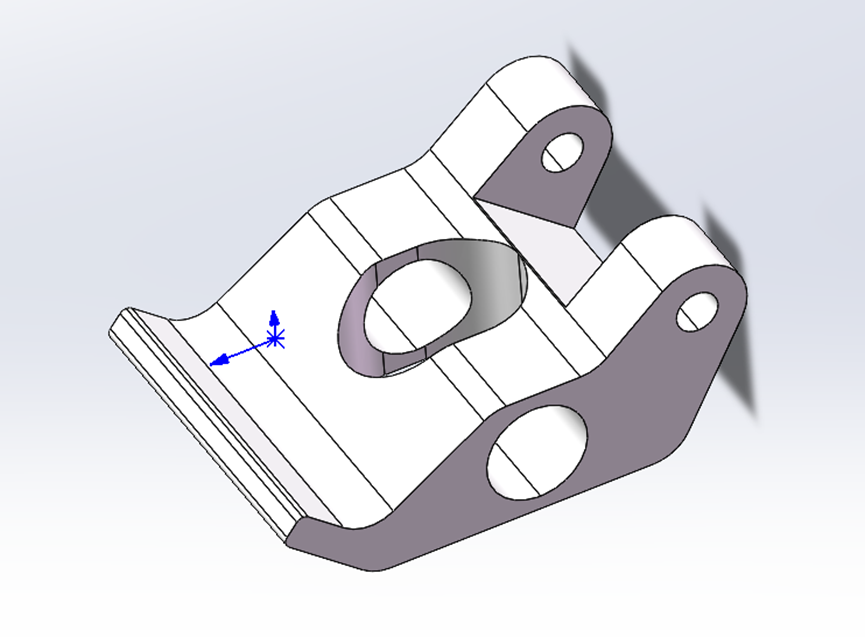

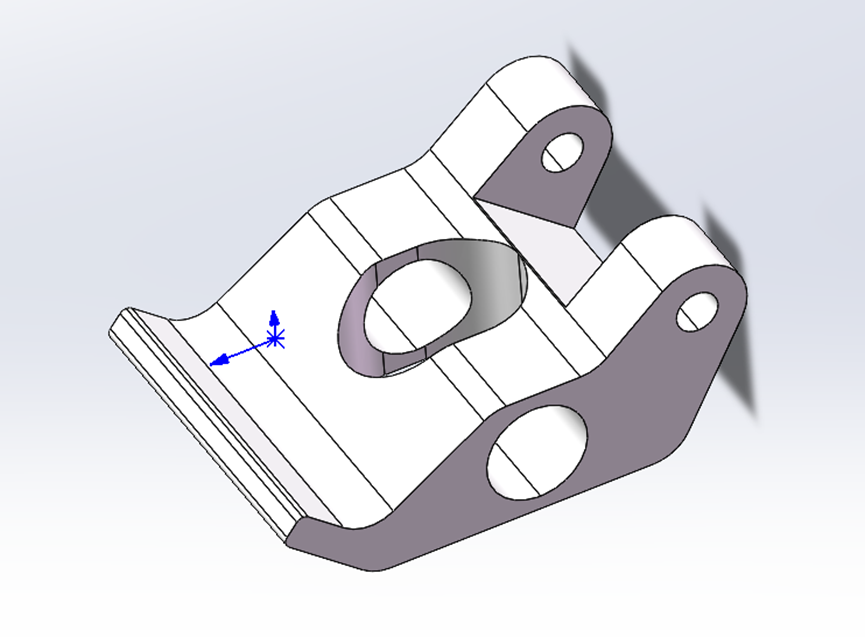

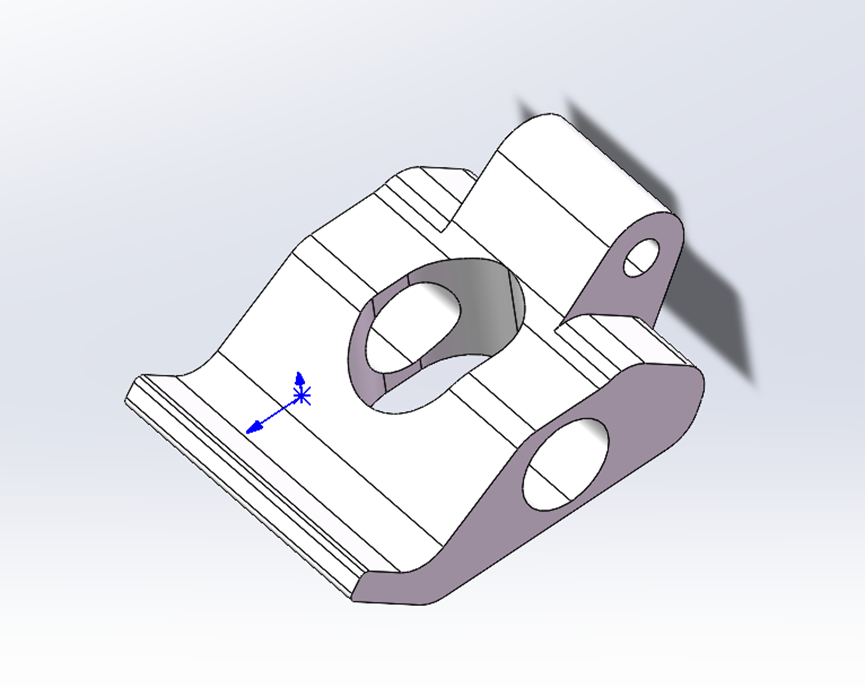

Here is the 3D drawings of the hinge:

For this shape, the customer wanted to directly CNC mill the aluminum block, forming it in one go.

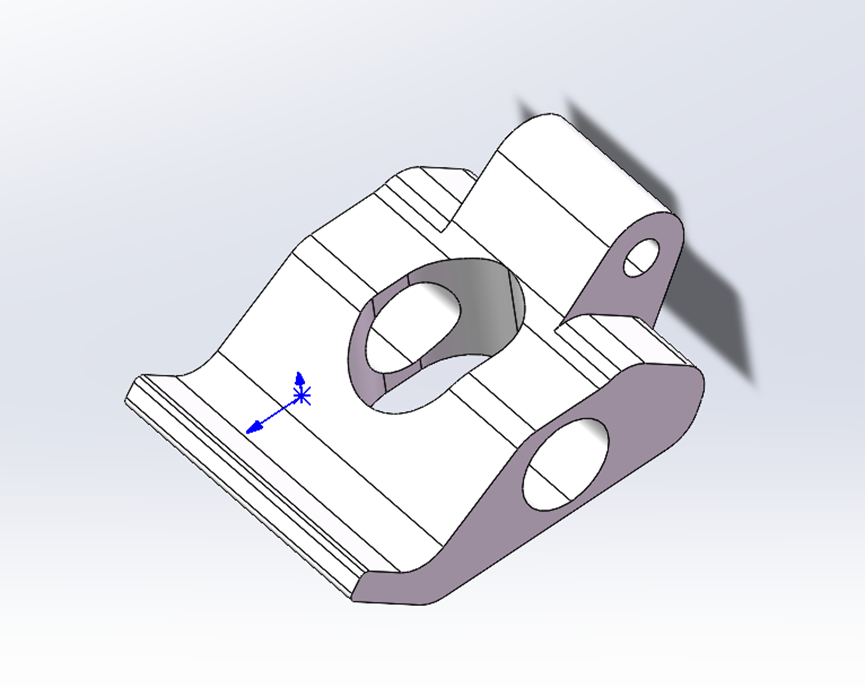

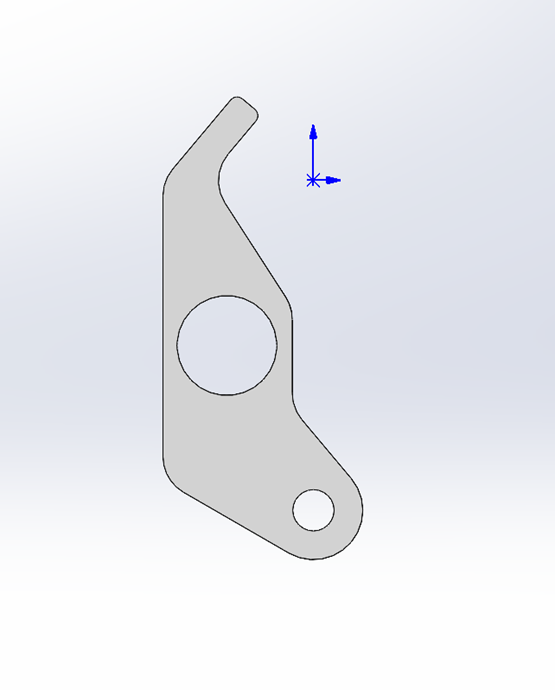

However, the cost will be high in this way. Then we analyzed the hinge's cross-section.

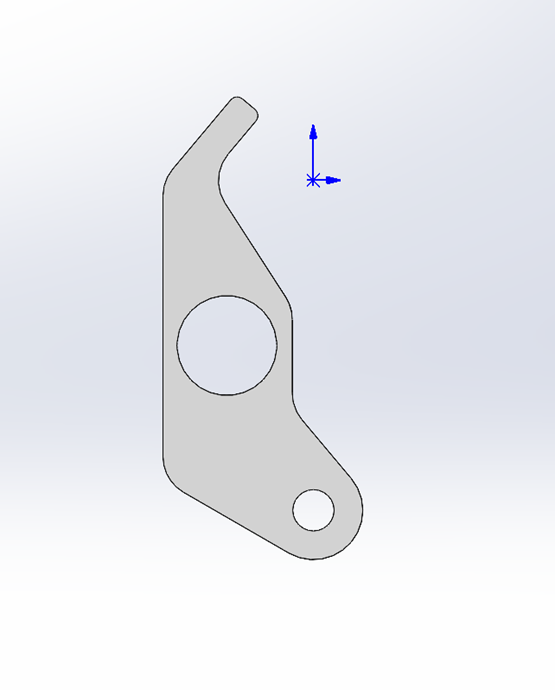

Both the cross section of the male and female is like this, in this way, we can use the aluminum extrusion process to form from the raw materials, and then process few secton by CNC milling and punch holes in the middle.

Making a mold like this costs approximately $500. 7075 material is difficult to extrude, but during discussions with the profile manufacturer, we received strong support. Naturally, our proposal was adopted. After processing, the product requires sandblasting.

Finally, the costs were reduced by 60%, the customer was very satisfied with our proposal.

Below is the finished hinges:

Packing

Each pair of hinges is individually packed in a ziplock bag for protection as the above picture. Each pair of hinges is individually packed into a ziplock bag for protection, then packed into a sturdy corrugated cardboard box, placed on a pallet, secured with straps, and finally wrapped with protective film.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски