Product Introduction

This is a hot forging eccentric bolt specifically engineered for installation on electricity meter boxes, boasting a set of distinctive features that set it apart from standard bolts and make it uniquely suited to its role. Unlike ordinary bolts, its design is highly specialized: the head is significantly larger, providing a broad, stable bearing surface that distributes clamping force evenly across the meter box's mounting points. The thread specification is M8, a common yet reliable size that balances holding power with ease of installation, ensuring compatibility with standard nuts and the pre-drilled holes in meter box frames.

Material and process

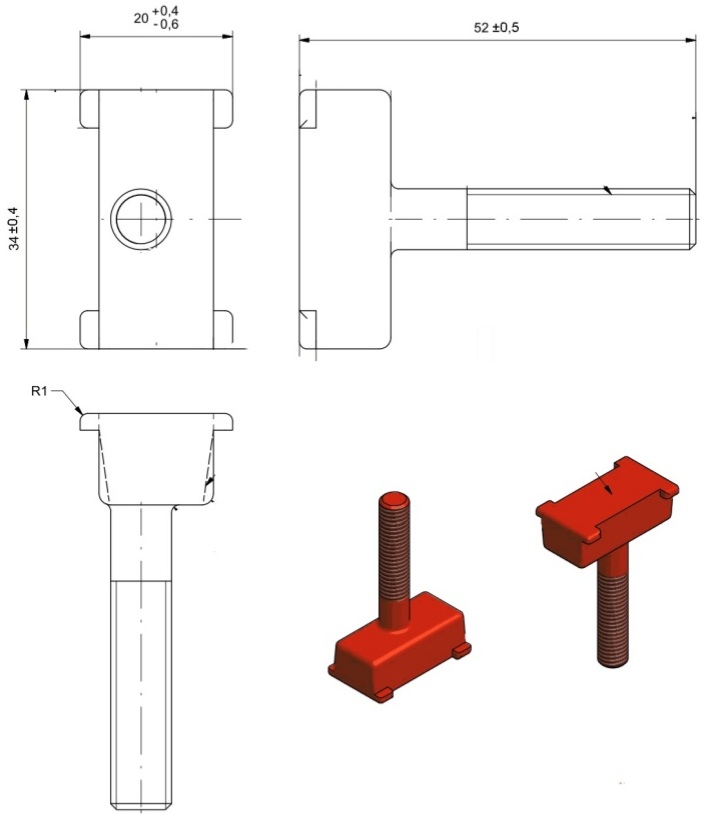

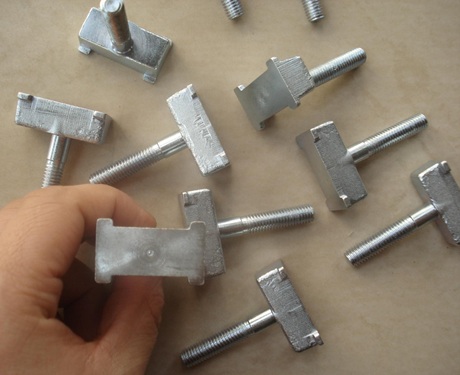

Drawings analysis

This is made from steel material by hot forging process. Here is the hot forging eccentric bolt's drawing:

We conduct a analyzation of this bolt when we received the drawings. This part needs OD 12mm bars to hot forging or hot press. After the material is punched out, two flat surfaces need to be machined. The threaded end needs to be CNC turning to 8mm and then roll the thread. The head section needs to be flat, so use CNC turning to remove the entire surface, and then it will be very flat. There will be an eccentric fixture needs to be made. CNC machining can't be used because it's much more expensive.

Then we move forward to the production. High-quality alloy steel is heated to temperatures between 800–1200°C, rendering the metal malleable yet retaining its structural integrity. The heated steel billet is then shaped under extreme pressure using custom dies, which imprint the eccentric geometry—including the offset shank, threaded section, and head in a single or multi-step forging operation. This method eliminates internal voids, aligns the metal's grain structure along the bolt's contours, and enhances tensile strength, impact resistance, and fatigue life compared to cold-formed or machined alternatives. Below is our hot forging machine:

Surface finish

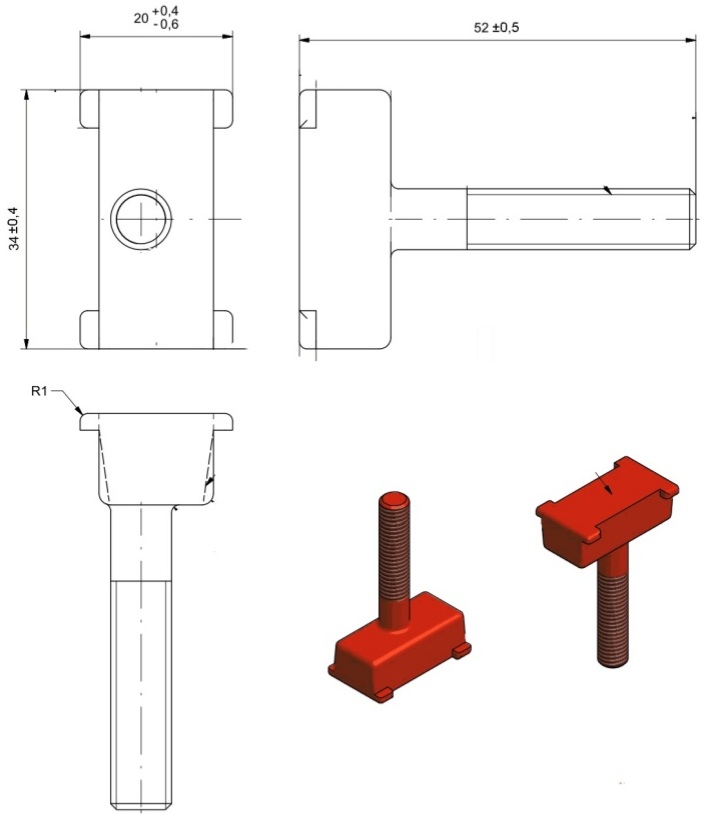

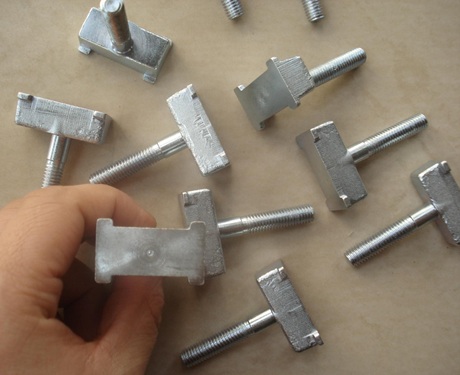

After finishing the hot forging, they are sent to undergo the white zinc plating, here are the finished bolts:

Packing

This eccentric nut is packaged individually in bubble bag to prevent scratches and bumps during handling. After individual wrapping, the bolts are placed into sturdy cardboard boxes, the boxes are then loaded onto pallets, with each pallet carefully stacked to ensure stability and maximize space efficiency. Finally, the entire pallet is wrapped tightly with stretch film, which secures the boxes in place, prevents them from shifting or scattering during transportation, and also offers some protection against dust and moisture.

Ningbo Joyo Metal products Co.,Ltd. excels in manufacturing a wide range of metal products, with strict quality control embedded in every stage of production.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски