Product Introduction

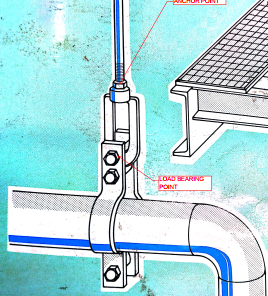

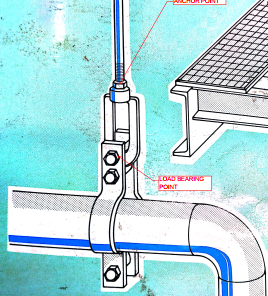

This part is a lifting eye nut, lifting eye nuts are commonly used in lifting operations. There are many kinds of the eye nut, they are differ from thread size. They are combined with bolts to facilitate the connection between lifting equipment and the objects to be lifted. They are widely applied in fields such as mechanical manufacturing, construction, shipbuilding, and equipment installation. Out eye nut is used on lifting the pipe, as the below skematic diagram show:

Material and Process

It's made from #45 steel by hot forging process. 45 steel is a medium carbon steel with a carbon content of approximately 0.42% - 0.50%. It offers a good balance between strength and ductility. Compared to low carbon steels, it has higher tensile strength. This makes it suitable for applications that require relatively high load bearing capacity, such as in lifting operations where the eye nut needs to withstand significant pulling forces.

The forging process compacts the metal, eliminating internal voids and porosity that might be present in cast parts. As a result, the hot forged 45 steel lifting eye nut has a higher density and better overall integrity, making it more reliable for safety - critical applications. It can form complex shapes with good dimensional accuracy. The process also aligns the metal fibers along the shape of the nut, which follows the direction of the applied load.

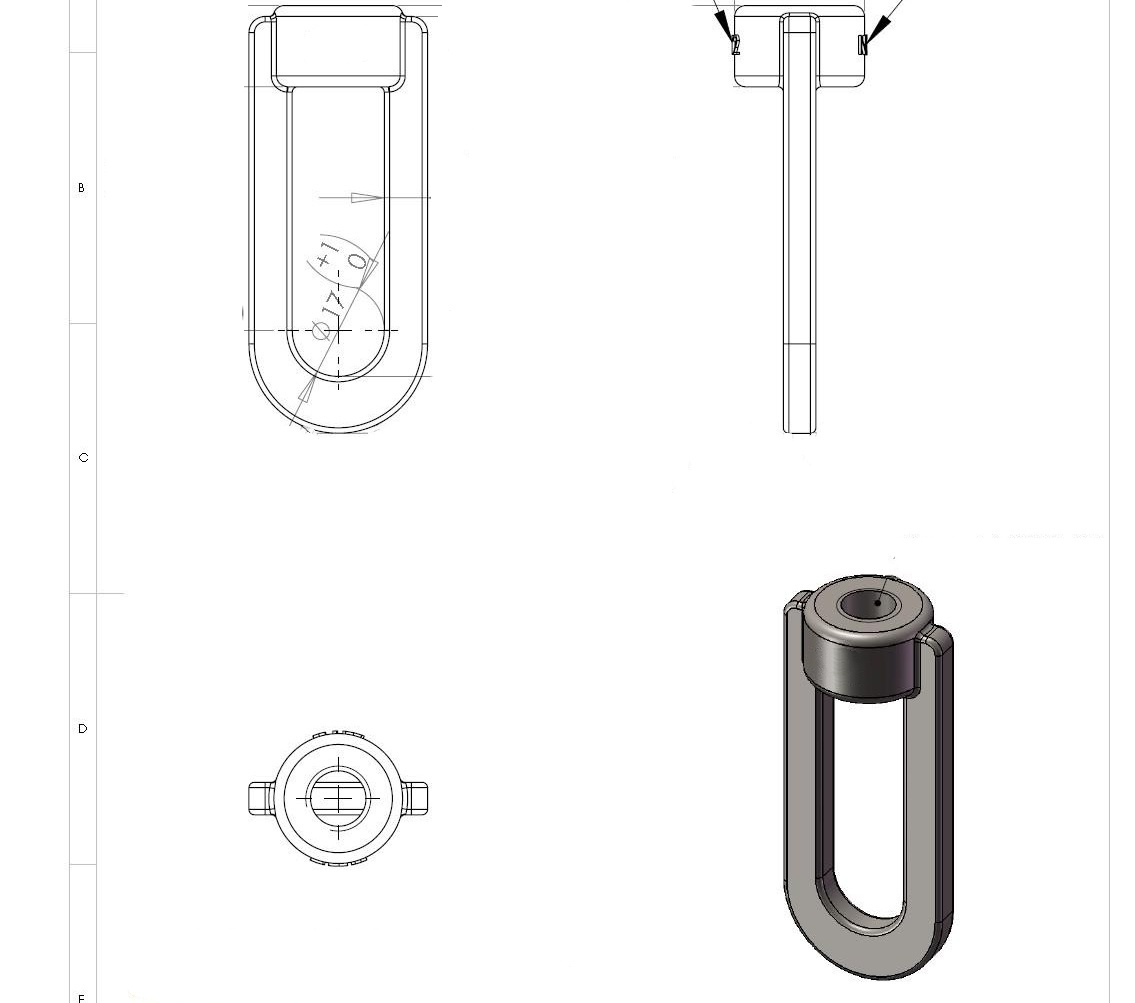

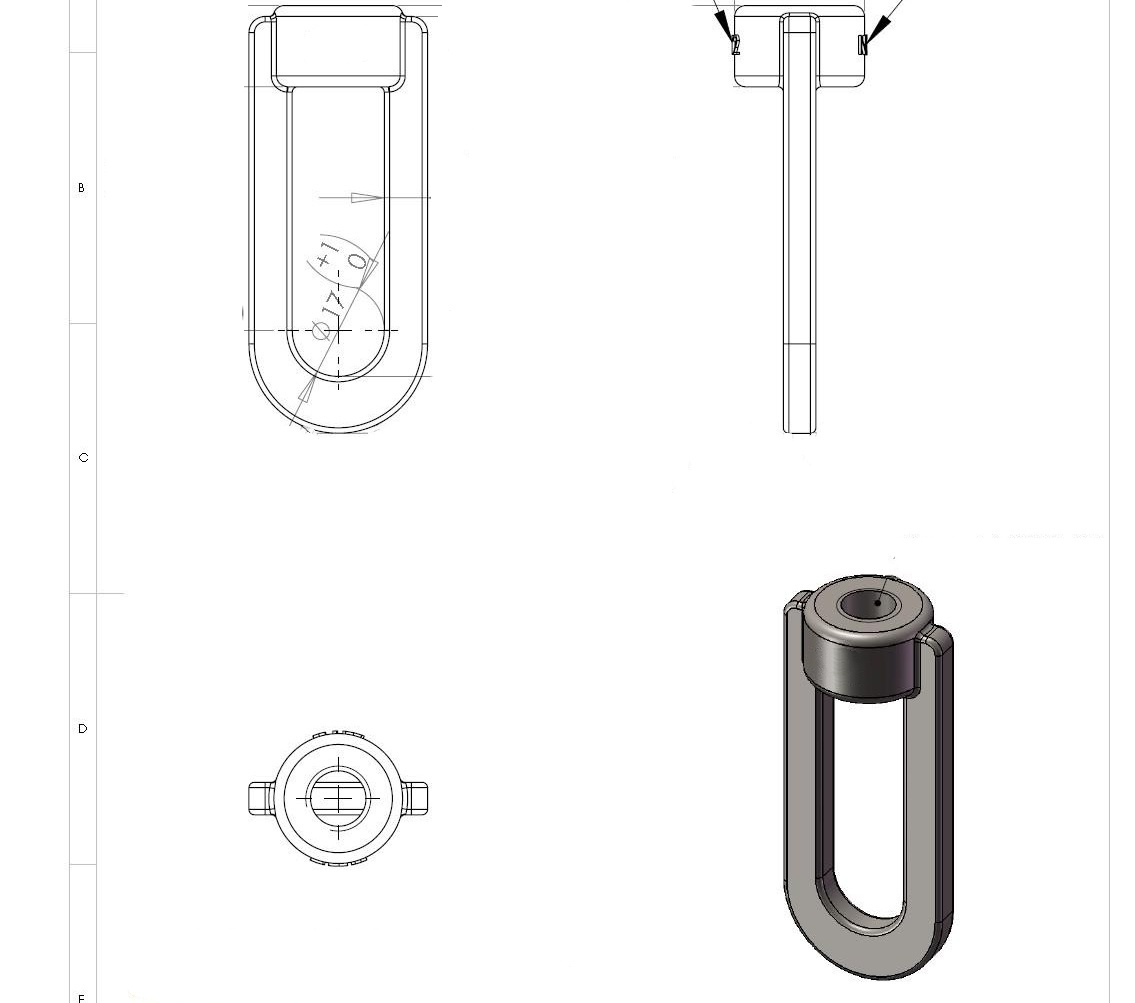

Here is the drawings of the eye nut:

After the material and process confirmed, we move forward to work the eye nut mold.

Hot forging molds are subjected to high temperatures, significant mechanical stresses, and wear during the forging process. H13 steel is a widely used mold material, which can withstand the repeated heating and cooling cycles during hot forging, which helps prevent cracking due to thermal stress.

The 45 steel blank is heated to a temperature range of about 1050 - 1200°C, at which the steel becomes malleable. The heated blank is then placed in a forging die.

Hydraulic forging presses apply pressure to deform the metal into the shape of the lifting eye nut. After forging, the nut is allowed to cool slowly to avoid internal stresses. Then, it undergoes processes thread cutting to meet the required dimensional.

Finally, the surface of the eye nut will be galvanized. This is a kind of hot dip zinc plated, different from nomal galvanizing, it is dipped into the molten zinc liquid, not electrolytic zinc solution. It looks darker than the nomal method and more expensive. Galvanizing forms a protective zinc coating that effectively prevents the 45 - steel substrate from rusting, enhancing corrosion resistance and extending the service life, especially for components used in harsh or outdoor environments.

Packing

Before packing, we will carefully inspect the eye nuts, checking item by item aspects such as dimensional accuracy, thread specifications, whether the geometric dimensions of each part meet the design and standard requirements, as well as surface quality—including checking for defects like cracks, blowholes, burrs, and whether the galvanized layer is uniform, free from peeling or rusting. Only after ensuring product quality do we proceed to the packaging stage.

We pack the products in cartons, which are then placed on pallets and covered with stretch film.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски