Product Introduction

This is a kind of U joint made from steel material by hot forging process. Its dimensions, as well as the design of the cross and bearing assemblies, are engineered to fit unique equipment specifications. Whether for heavy-duty trucks, industrial machinery, or agricultural equipment, the CNC-machined mating surfaces ensure a precise fit with connected shafts, minimizing vibration and extending service life.

Material and process:

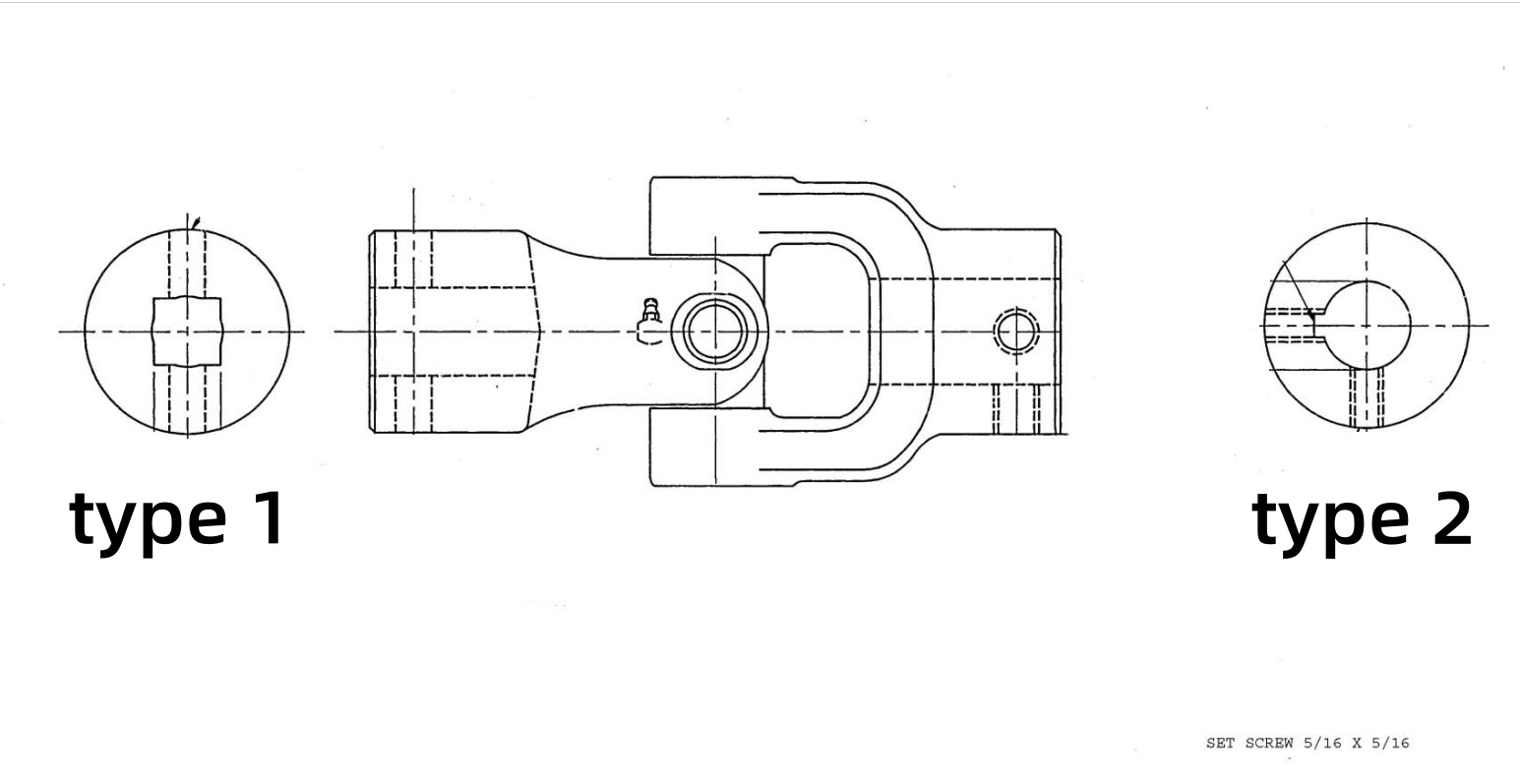

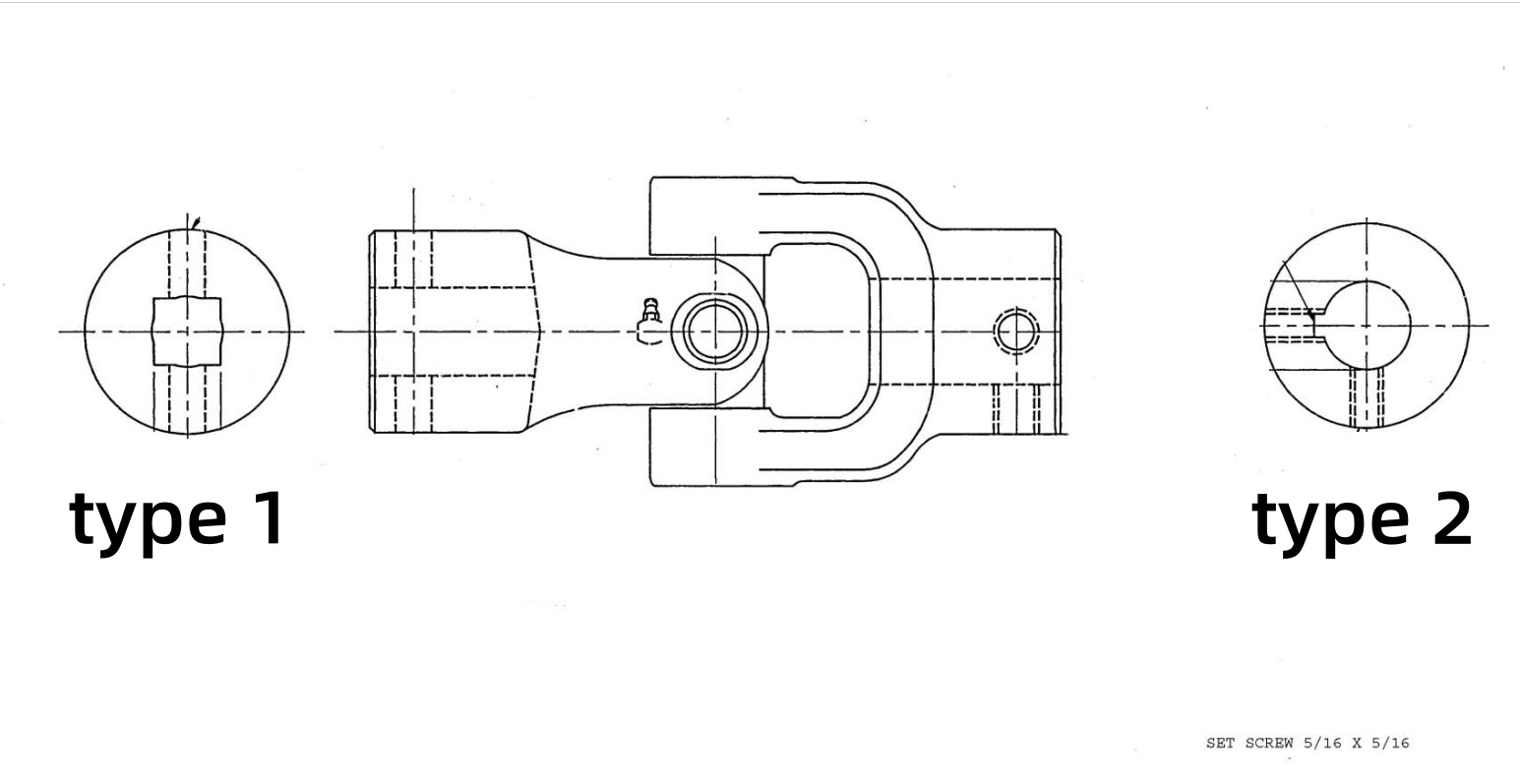

Drawing analysis

There are many different size and style U joints in the market, we have worked 2 kinds steel U jionts with different connector. Here is the drawings of the U joint:

They are made by hot forging process. The hot forging process is a precision manufacturing method that shapes metal into desired forms using heat and pressure, ideal for creating strong, durable components.

Manufacturing Process

The raw material steel billets are heated in a furnace to a critical temperature range. This heating softens the material, making it malleable while retaining its structural integrity, allowing it to be shaped without cracking under pressure.

Next, the heated metal is transferred to a forging press, where it is placed into custom dies, precisely machined tools with cavities matching the component's final shape. Under high mechanical force, the metal is pressed into the die, filling the cavity and taking on the die's contours. After forging, the component undergoes trimming to remove excess material formed during the process, ensuring clean edges and precise dimensions.

When the forging finished, they are sent for black powder coating. Finely ground pigment and resin particles are charged and sprayed onto the grounded components, creating an even, consistent layer that wraps around edges and complex contours areas where liquid paints might sag or thin. The parts are then cured in a high-temperature oven, which melts and fuses the powder into a hard, smooth finish.

Here is the U joint assembly after everything are finished:

Packing

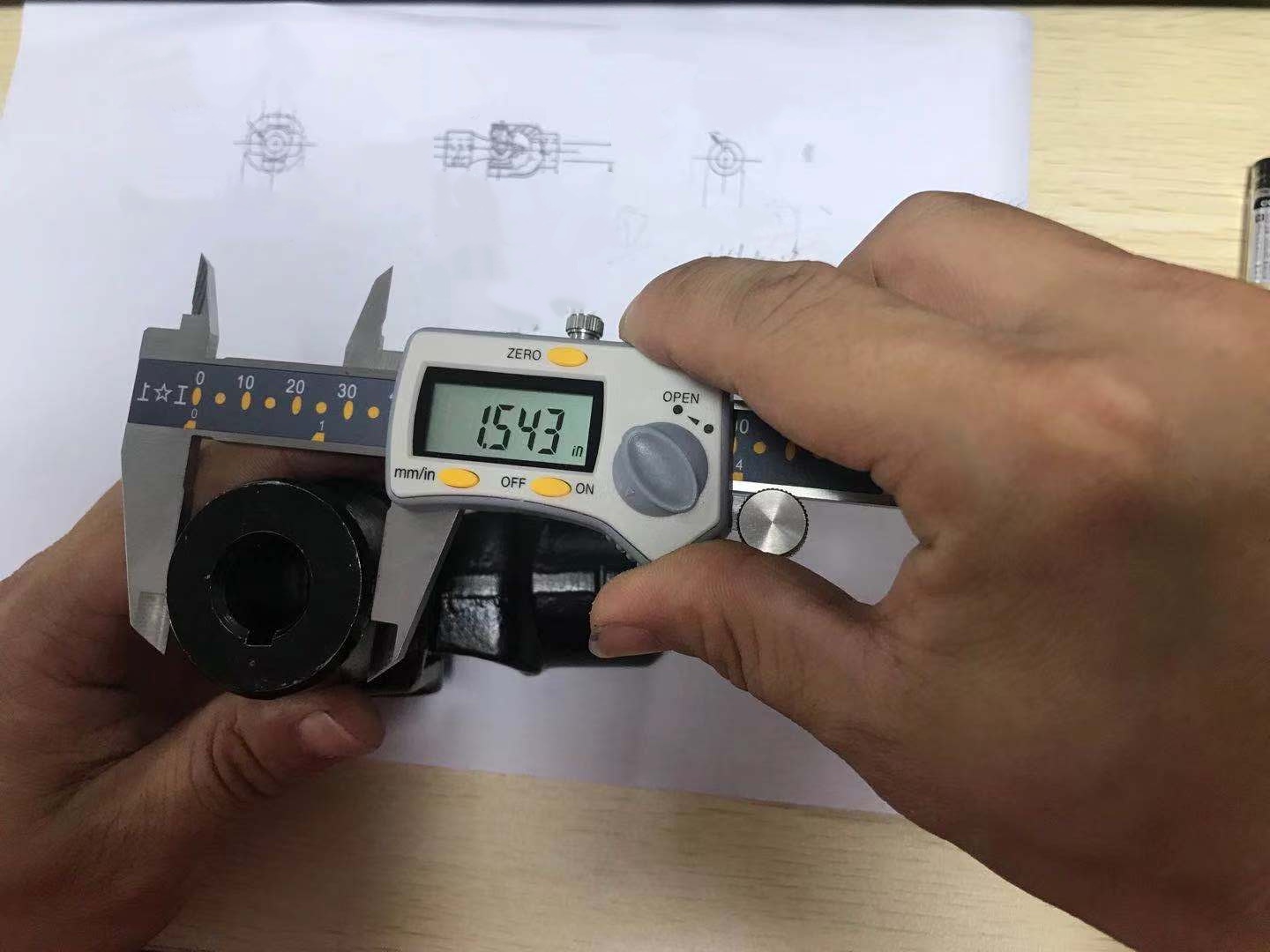

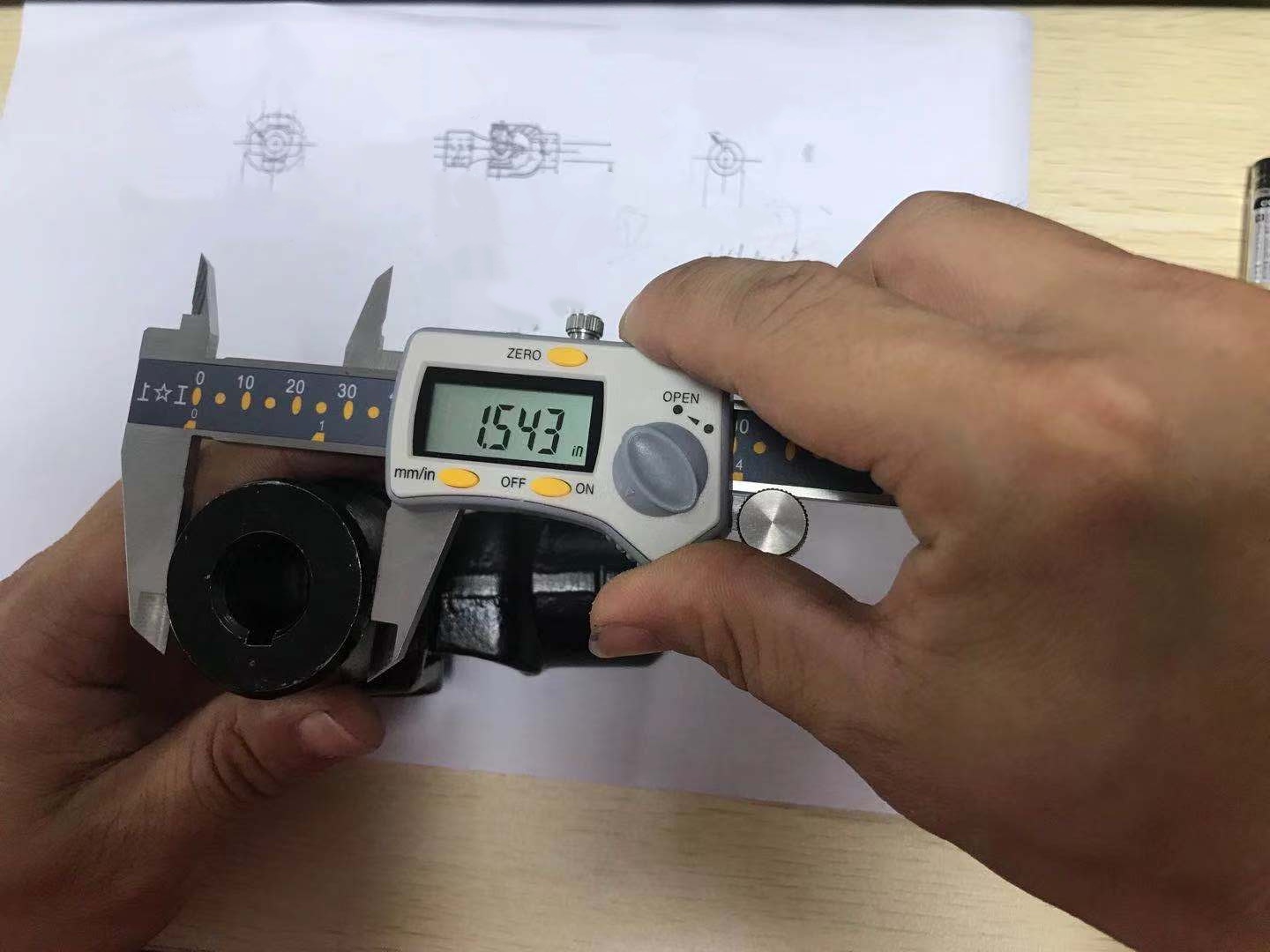

Inspection

Before packing, we inspect the dimision carefully.

Each U-joint is individually packaged in its own dedicated box before being consolidated into larger shipping crates. This two-layer packaging approach is designed to maximize protection during transit, the individual boxes often made of sturdy corrugated cardboard material, to cradle each U-joint securely, preventing scratches, dents, or contact between components that could cause damage to their precision-machined surfaces or threaded parts.

At this point, the project has been successfully completed, the customers were also very satisfied.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски