Product Introduction

This is a steel lost-wax casting bracket, whether it's bearing heavy loads, withstanding extreme temperatures, or fitting into tight, specialized spaces, custom steel lost wax casting brackets deliver precision, strength, and adaptability, making them indispensable for advanced engineering applications.

Material and process

Material introduction

It's made from #45 steel by lost wax casting, or water glass casting. It's light and weighs 35g, there are left and right part to use cooperatively. The custom nature ensures that every aspect, from intricate structural designs to exacting dimensional tolerances, aligns with unique project needs.

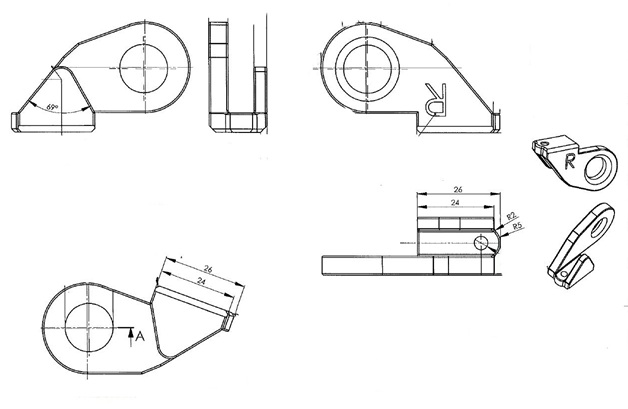

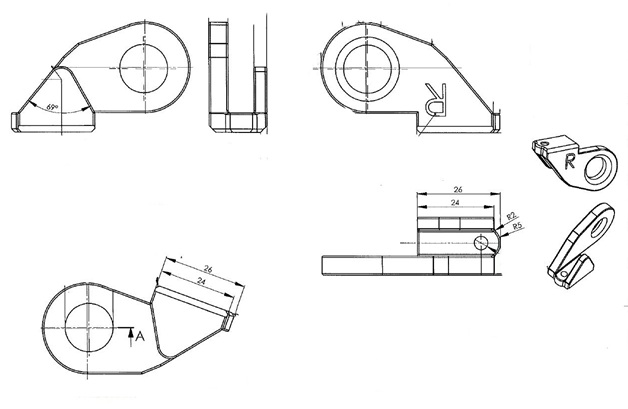

Drawing analysis

After careful consideration, we confirmed that lost wax casting was the optimal manufacturing process for fabricating the bracket. This decision was based on multiple factors, such as the need for high precision in the bracket's complex geometry, the requirement to achieve intricate details, and the desire for a cost effective solution.Here is the bracket drawing:

Manufacturing process

First, the fabrication of wax patterns and the assembly of the wax tree are essential initial steps. The wax patterns must be crafted with extreme precision, as they serve as the exact replica of the final steel bracket.

Once the individual wax patterns are completed, they are carefully attached to a central wax sprue to form a wax tree. Then, the wax tree undergoes a meticulous investment casting preparation process. It is carefully dipped into a precisely formulated water glass slurry, which acts as a bonding agent. Immediately after, it is coated with refractory sand, the particles of which adhere to the slurry covered wax tree, building up a protective and mold forming layer.

The coated wax tree is then transferred to a specifically designed drying room. In this controlled environment space, with regulated temperature and humidity, the water in the slurry evaporates, and the layer hardens. This dipping coating drying cycle is repeated 5 to 8 times.

Once the desired number of layers is achieved and the shell is sufficiently robust, it is placed into a furnace. Inside the furnace, the shell is baked at a high temperature. This baking process serves multiple purposes: it fully dries the shell, removes any remaining moisture, and also melts and removes the wax tree inside, leaving behind a precise, hollow mold cavity.

Then the molten steel heated to its liquid state at extremely high temperatures, is carefully poured into the empty shell mold. The molten steel fills the cavity, taking on the exact shape of the original wax tree. Then, we wait for the molten steel to cool down naturally within the shell. As it cools, the steel solidifies, forming the final custom steel lost wax casting bracket.

Inspection

The hole in the middle, 15H7, is very important.

After processing, a gauge is needed for inspection.

Packing

The most crucial point is that these products must not be flattened to prevent deformation. This is not allowed like below picture.

So we conduct a comprehensive inspection of the brackets. Qualified brackets are packed with bubble bag individually and put into the carton. Then we place the goods on pallets and wrap them with plastic film.The pallets provide a stable base for consolidating the goods, preventing shifting during handling and transportation.

Wrapping with plastic film, typically stretch film, secures the items tightly to the pallets, creating a unified, stable load. This not only protects the goods from dust, moisture, and minor impacts but also ensures they remain intact and properly positioned throughout the logistics chain, from warehousing to final delivery.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски