Product Introduction

This investment casting butterfly nut is crafted from 35# steel, a medium-carbon steel, renowned for its balanced mechanical properties. Whether used in machinery assembly, fixture installations, or equipment maintenance, this butterfly nut combines the versatility of medium-carbon steel with the accuracy of investment casting, delivering a functional, durable component tailored for efficient.

Material and process

Material introduction

This custom investment casted wing nut is made from 35 steel and we has 3 types wing nuts which are M6, M8, M10. Their threads and chamfers are different. 35# steel imparts the butterfly nut with moderate strength and good toughness, making it suitable for applications requiring both secure fastening and resistance to moderate loads. The precision casting technique allows for consistent replication of its unique geometry, ensuring the winged design maintains uniform thickness and structural integrity across batches.

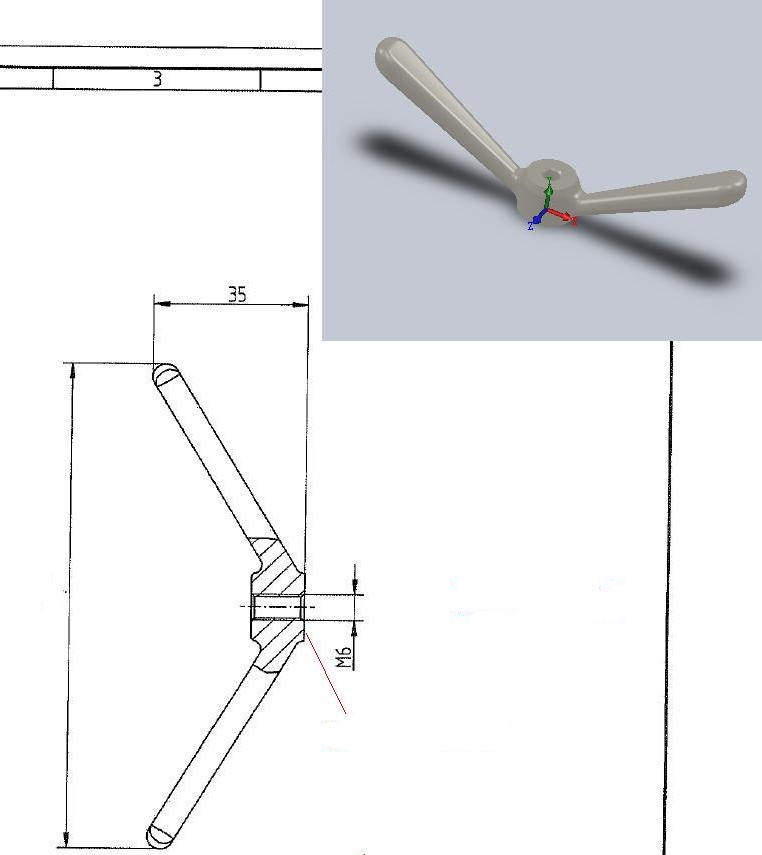

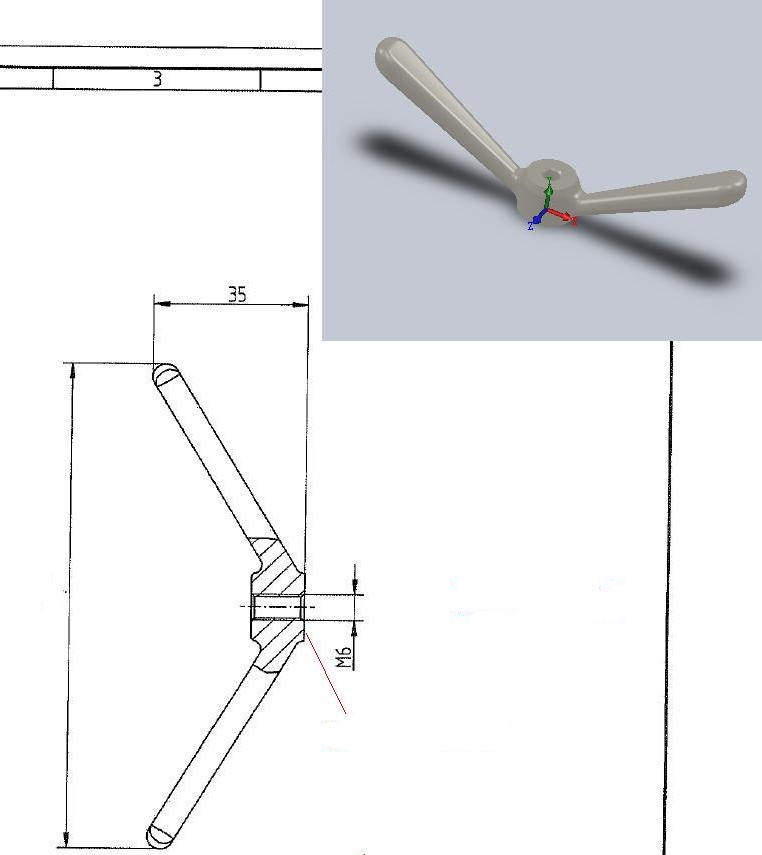

Drawings analysis

Here is the M6 wing nut drawings:

Investment casting is also known as lost wax casting, which is an ancient and complex manufacturing process celebrated for its ability to produce high-precision, complex-shaped components.

Manufacturing processes

The precision casting process, or lost-wax casting, follows these key steps:

First, a wax pattern of the nut is created, often using injection molding, and fabricate the wax tree.

This pattern is then coated with multiple layers of slurry and sand to form a hard shell. Once the shell dries, the wax is melted and drained out, leaving a hollow ceramic mold. Molten steel is poured into the mold, filling the cavity. After cooling, the shell is broken away, revealing the metal casting as below:

Then the wing nuts were sent to be tapping different size thread.

Surface finish

Surface treatments zinc plating is often applied to improve corrosion resistance, extending its service life in industrial, mechanical, or structural settings where reliable, tool-free fastening is essential.

Packing

Inspection

Before shippment, we conduct full inspection of the wing nut, mainly check the surface and the dimensions.

For the surface, the color must be uniform; regarding dimensions, they must comply with the required tolerances. This ensures both visual consistency and precise fit, meeting the functional and aesthetic standards of the product in its application. Here is the gauge used to inspect the thread:

Palletizing

Then we move to pack the wing nut. They are packed with individual bubble bag to product and then put into cartons.

Cartons are stacked on the pallet and wrapped with flim to avoid scattering.

Ningbo Joyo Metal Products Co., Ltd. has the capability to oversee and integrate all processes comprehensively, including custom component manufacturing, prototype development, and surface treatments. By managing the entire workflow in-house, we streamline communication, reduce lead times, and maintain strict quality standards, ensuring that each custom component aligns perfectly with your project needs, whether for small-batch trials or large-scale production.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски