Product Introduction

This is a muti-station step shaft, which is made from 12L14 material by CNC machining process. It's used in the mechanical transmission system, it can serve as a transmission shaft to transfer power from one component to another. Meanwhile, the steps are utilized to install parts, playing roles in positioning and supporting.

Material and process

Material introduction

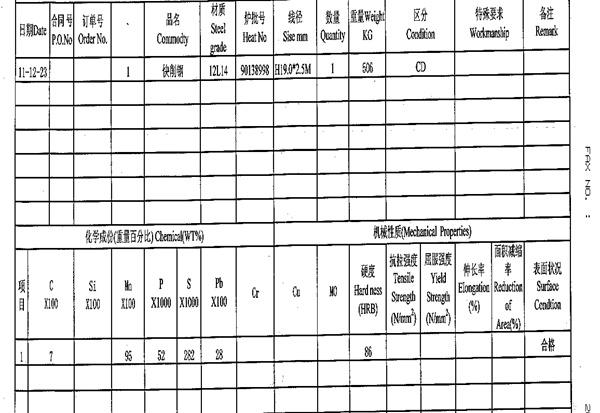

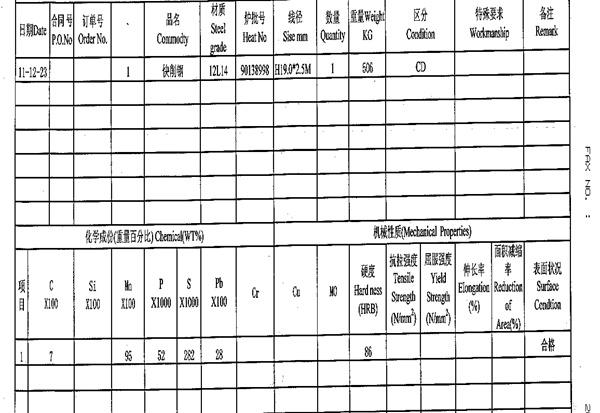

This muti-station shaft is made from 12L14 steel rod, which is a kind of a free-cutting structural steel, often used in the manufacture of precision parts. The core advantage of 12L14 steel is its excellent machinability. Through the combined effect of Pb and S, it can make material break more easily, reduce tool wear, and improve processing efficiency and surface finish. It is especially suitable for the multi-station shafts. To confirm material quality, we have conducted inspections, and the following is the inspection report.

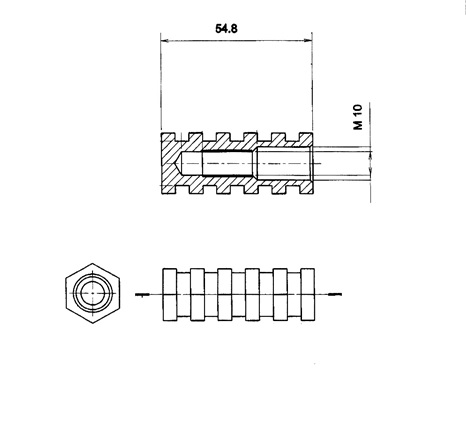

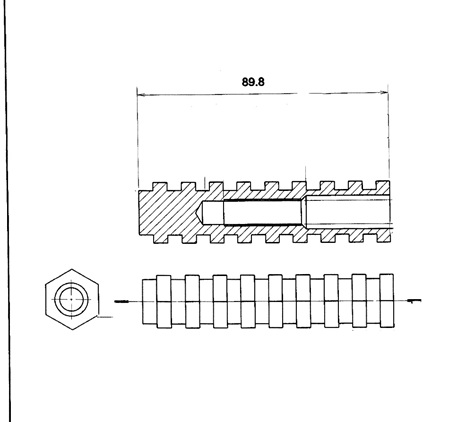

Drawings analysis:

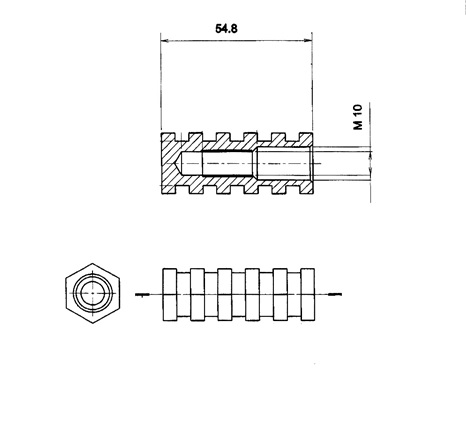

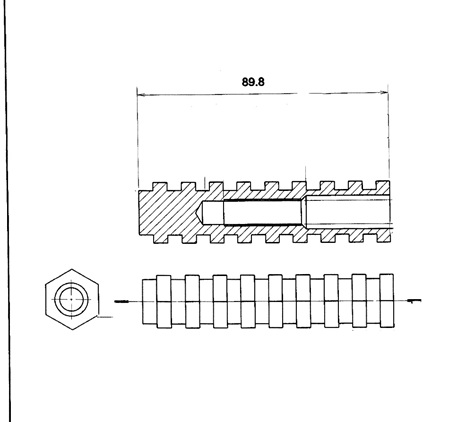

Here are 2 different size drawings of the shafts:

shaft drawings 1

shaft drawings 2

Manufacturing Process

The shafts need to be made by automatic lathe machine. An automatic lathe is a type of metal-cutting machine tool with a high degree of automation. It can automatically complete multi-process machining of workpieces such as turning, drilling, boring, tapping, etc., through preset programs or mechanical structures like cams and levers, without the need for continuous manual operation. It is suitable for processing small and slender parts, such as shafts, bolts, bushings, etc., and its production speed is much higher than that of ordinary lathes.

Most are equipped with automatic bar feeding mechanisms to achieve continuous and uninterrupted production, widely used in the efficient production of large quantities of standardized parts.

For 89.8mm step shafts, they were processed in two steps, we worked one end first:

Finished products

The surface of the product should also be coated with a layer of anti-rust oil, and cleaned with ultrasonic waves. Then come out the finished products:

Packing

There is a layer of plastic film before put in carton to isolate the air and reduce oxidation. Finally laid the cartons on pallet and wrapped with protective film to avoid scattering.

packed in carton-1

packed in carton-2

Ningbo Joyo Metal Products Co., Ltd. provides one-stop service, and we can handle any process of customing metal, from material selection to packaging.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски