Product Introduction

The vacuum block is a designed to manage, control, or distribute vacuum pressure within a system. It often serves as a junction, manifold, or mounting base for vacuum-related parts, ensuring efficient flow of vacuum forces.

Material and process

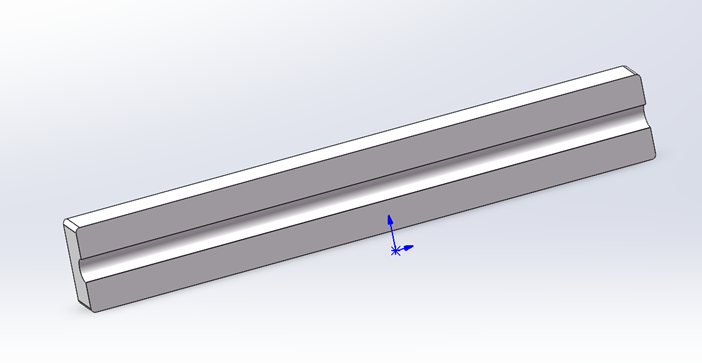

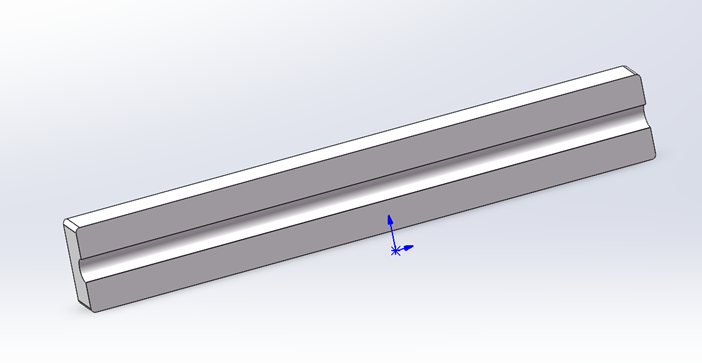

Material introduction

It is made from aluminum material by cnc milling process. For product processing, we use square rod aluminum alloy materials, with dimensions of 30mmx 20mm x128mm.

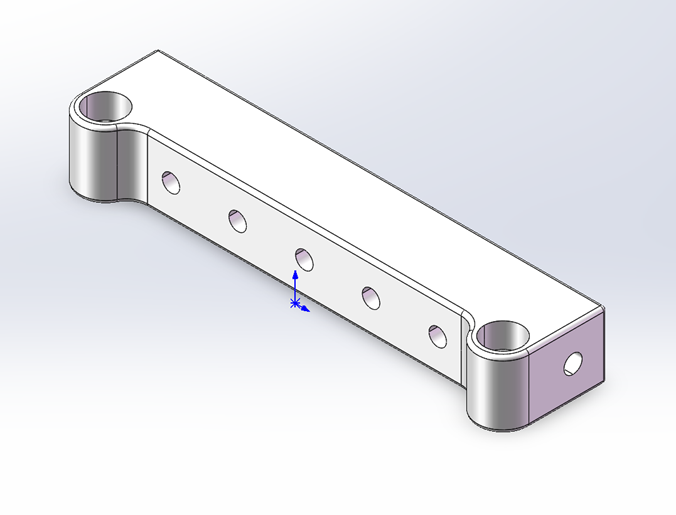

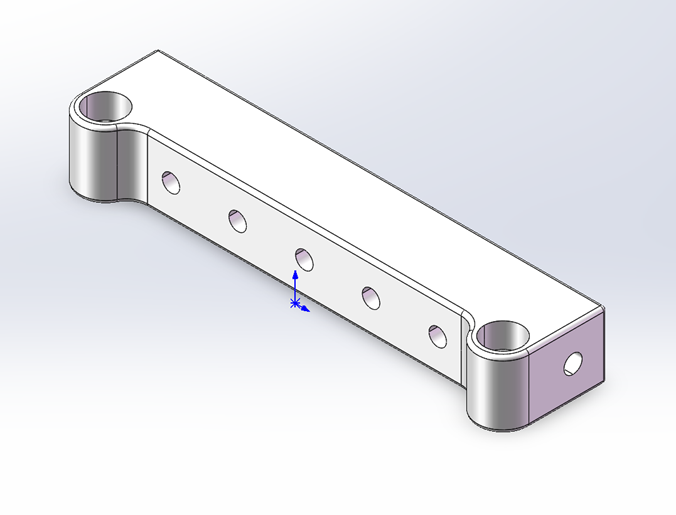

Drawing analysis

The middle of the part is empty and holes need to be drilled on both sides and connect them to the middle position. Only in this way can hit it straight, or it's easy to miss. Below are the vacuum block 3D drwaings:

Manufacturing process

They are processed by CNC milling to form. It needs to play on both ends of the long hole 1/4 "NPT thread, side is 5 1/8" NPT thread. NPT (National Pipe Taper) is a standardized tapered thread design used primarily in North America for connecting pipes and fittings in fluid systems. NPT threads are tapered, not parallel, meaning the diameter of the thread increases or decreases along its length.

Surface treatment

After the parts are processed, they are sent for sandblasting, below is the vacuum block after sandblasting:

Then carry out black anodized treatment on them. Overall have qualitative feeling, then the product assembly corresponding barb fitting.

Packing

They are inspected carefully before packing, mainly for dimension and surface. The qualified vacuum block are wrapped with bubble foam and put into cartons. Then the cartons are laid on the palled fixed with strap. These wrapped items are then carefully placed into sturdy cartons, with additional filler materials used as needed to prevent shifting inside the boxes.

Different vacuum blocks

Apart from the vacuum block described above, we have also developed and produced a wide range of custom vacuum block variants tailored to diverse industry needs and application scenarios. These designs vary in structure, material, and functionality to address specific operational requirements.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски