Product Introduction

This is a kind of CNC milling component which is used in microwave communication industry, we just work the shell or the foundation. This integration of precision machining and material expertise ensures the components meet the stringent functional demands of microwave communication equipment.

Material and process

The component is made from 303 stainless steel and made by CNC turning process at once. Stainless steel are commonly used, selected based on their electrical conductivity, corrosion resistance, and mechanical stability.

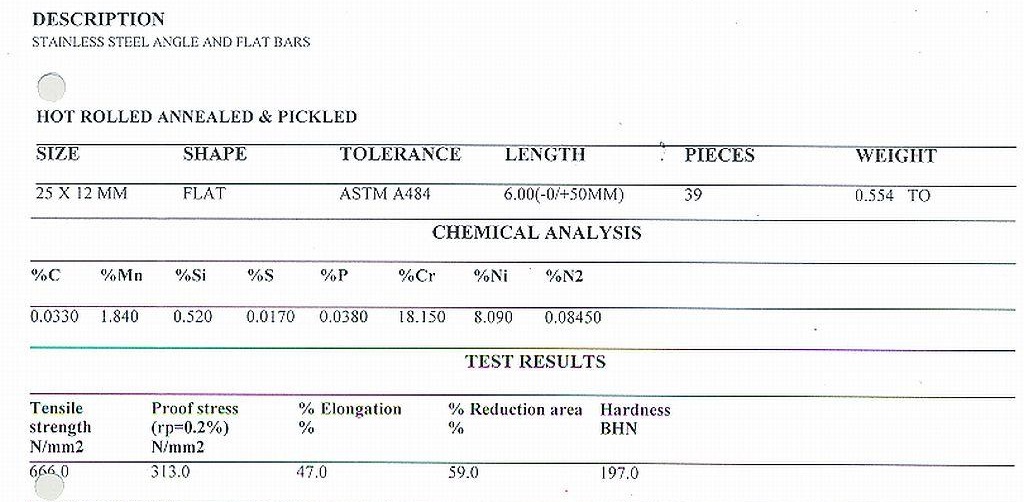

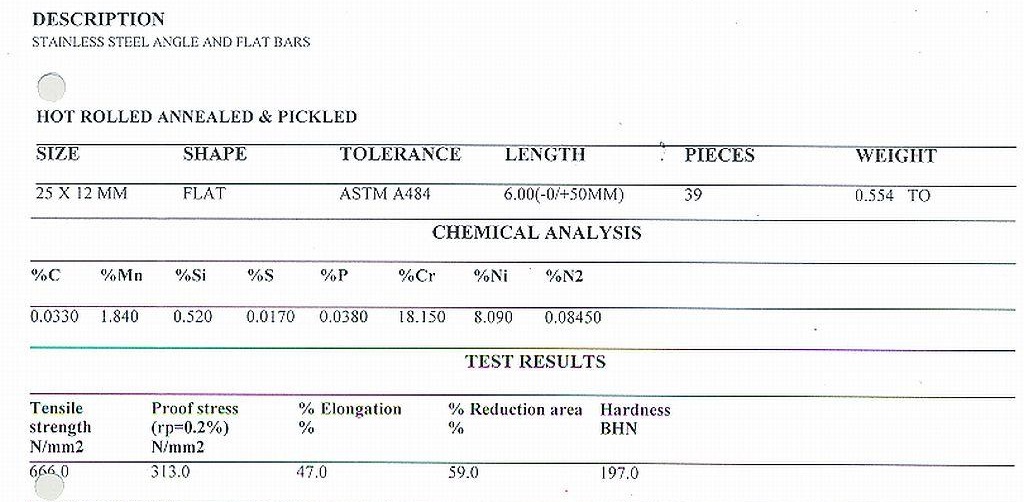

Before the production, we send the material for testing, here is the report:

CNC machining enables the production of complex geometries, including intricate waveguide channels, threaded interfaces with consistent accuracy, critical for minimizing signal reflection and ensuring optimal microwave transmission.

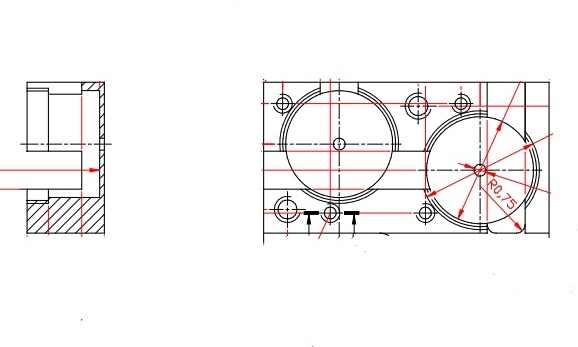

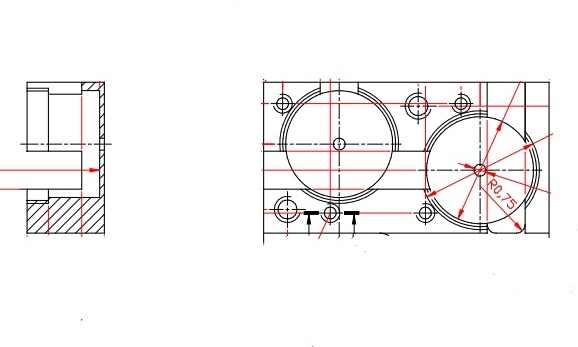

Here is the waveguide component drawings:

The component size is 24*21mm, it's quite challenging to process, with key difficulties lying in its small size, high precision requirements, and complex processing steps.

Crafted from 303 stainless steel, it is fully CNC milled entirely from a single block of material in one continuous operation. The small dimensions demand extreme stability from the machining equipment, as even minimal tool deflection can compromise accuracy. Meanwhile, tight tolerances require high-precision CNC systems and sharp, wear-resistant tools to ensure every detail, from tiny holes to intricate contour.

After the samples were completed, we sent them to test tolerance, flatness, surface roughness, etc.. There were some areas that did not meet the standards at first time. We made improvements and re-worked the samples.

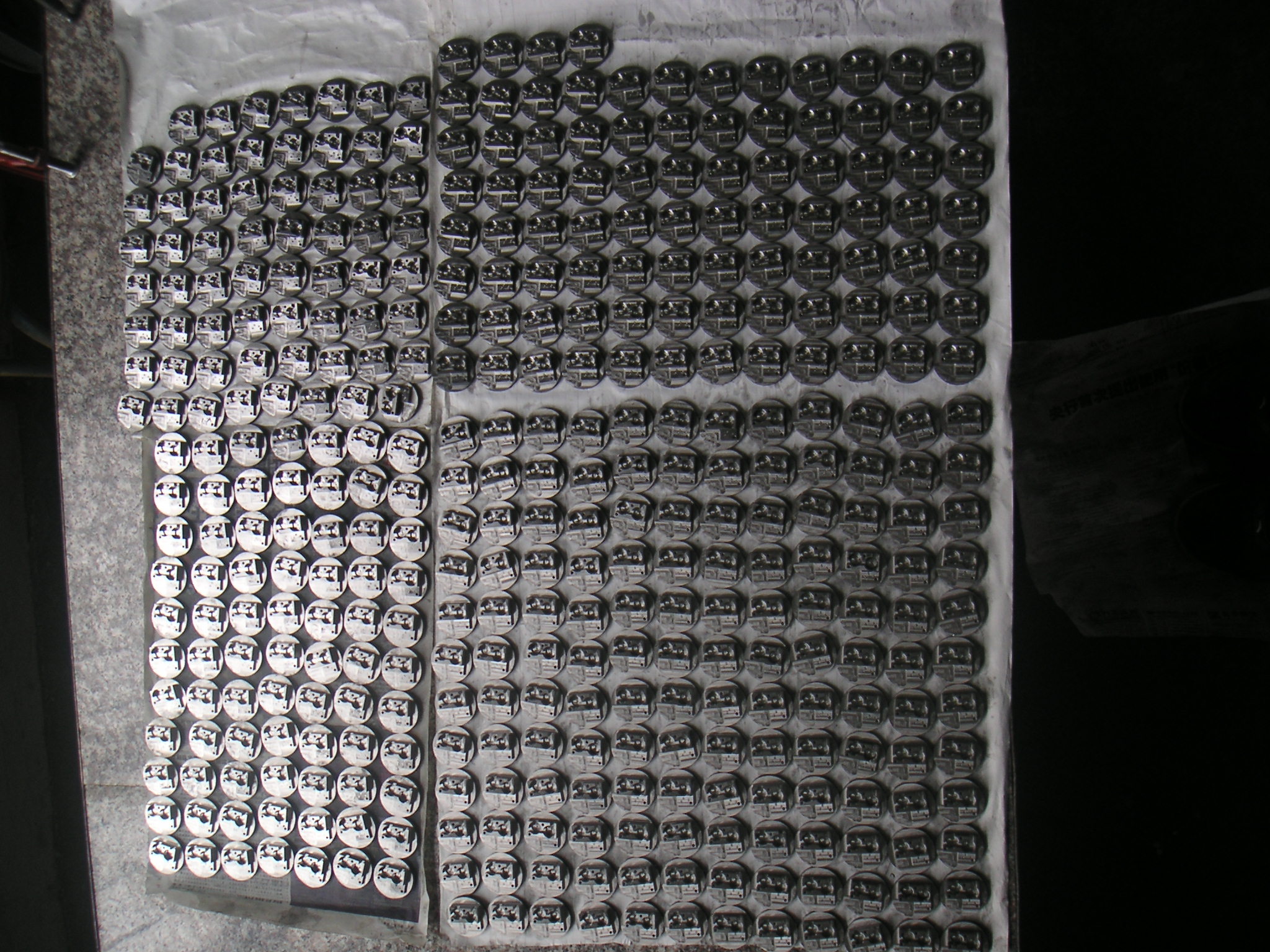

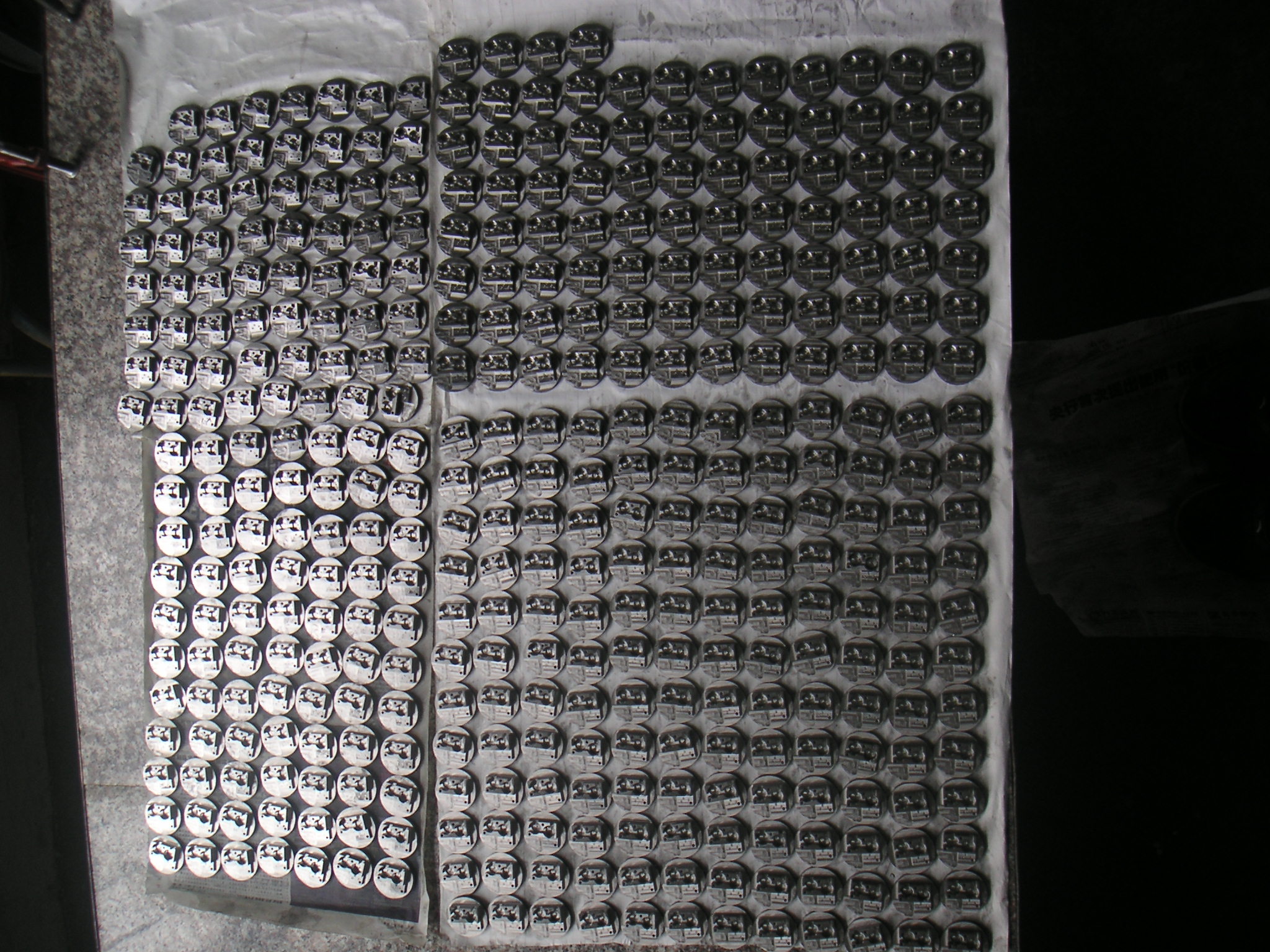

Finally the samples were qualified and get approval, we move forward for the mass production.

Adding to the complexity is the 18K gold plating on the surface. The plating must adhere uniformly to the small, precision-machined surfaces without affecting dimensional accuracy, requiring strict pre-plating treatments to remove any machining residues. This ensures the gold layer is smooth, consistent in thickness, and functional standards for the final product.

Packing

We conduct thorough inspections of both surface quality and dimensions before shipment. This includes checking for uniform surface finishes, absence of defects like scratches or blemishes, and verifying that all dimensional parameters strictly meet the specified tolerances. Only products passing these rigorous checks are approved for delivery, ensuring they meet the quality requirements.

Finally, the products are packaged and palletized. Each item is first properly wrapped or boxed to prevent scratches or damage, then stacked on standard pallets. The palletized goods are secured with stretch film and strapping to ensure stability during transportation, minimizing shifting or collision risks. This final packaging step ensures safe handling and efficient logistics from our facility to destination.

Ningbo Joyo Metal Products Co., Ltd. is always striving for breakthroughs, no matter how precision-demanding the components are, we spare no effort to deliver them with excellence. Whether it's ultra-tight tolerances, intricate microstructures, or complex geometries, our commitment to advancing machining techniques and quality control drives us to meet even the most stringent requirements.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски