Product Introduction

This is a kind of adapter made from Duplex 2507 material by CNC Machining process. It's used for water filter industry.

In the water filter industry, where equipment used in harsh environments, and long-term usage. The reliability and durability of core components decide the filtration efficiency, equipment lifespan, and operational costs. Our Custom Duplex 2507 CNC Machining Adapter is customized for these industry features, integrating material performance and precision machining to make the adapter.

Material and process

Material introduction

This adapter is made from Duplex 2507 material, it is UNS S32750, and EN 1.4410 as well.

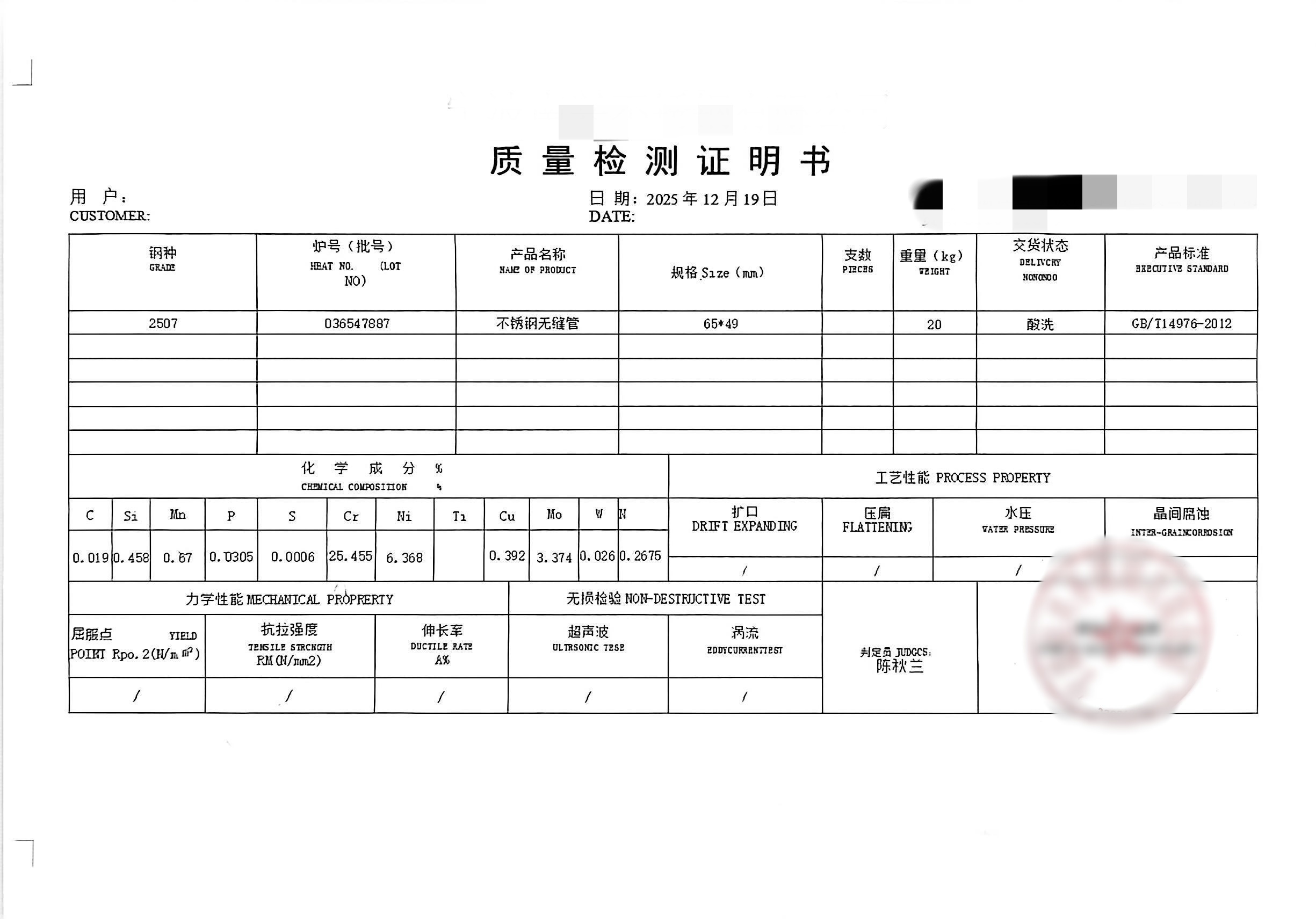

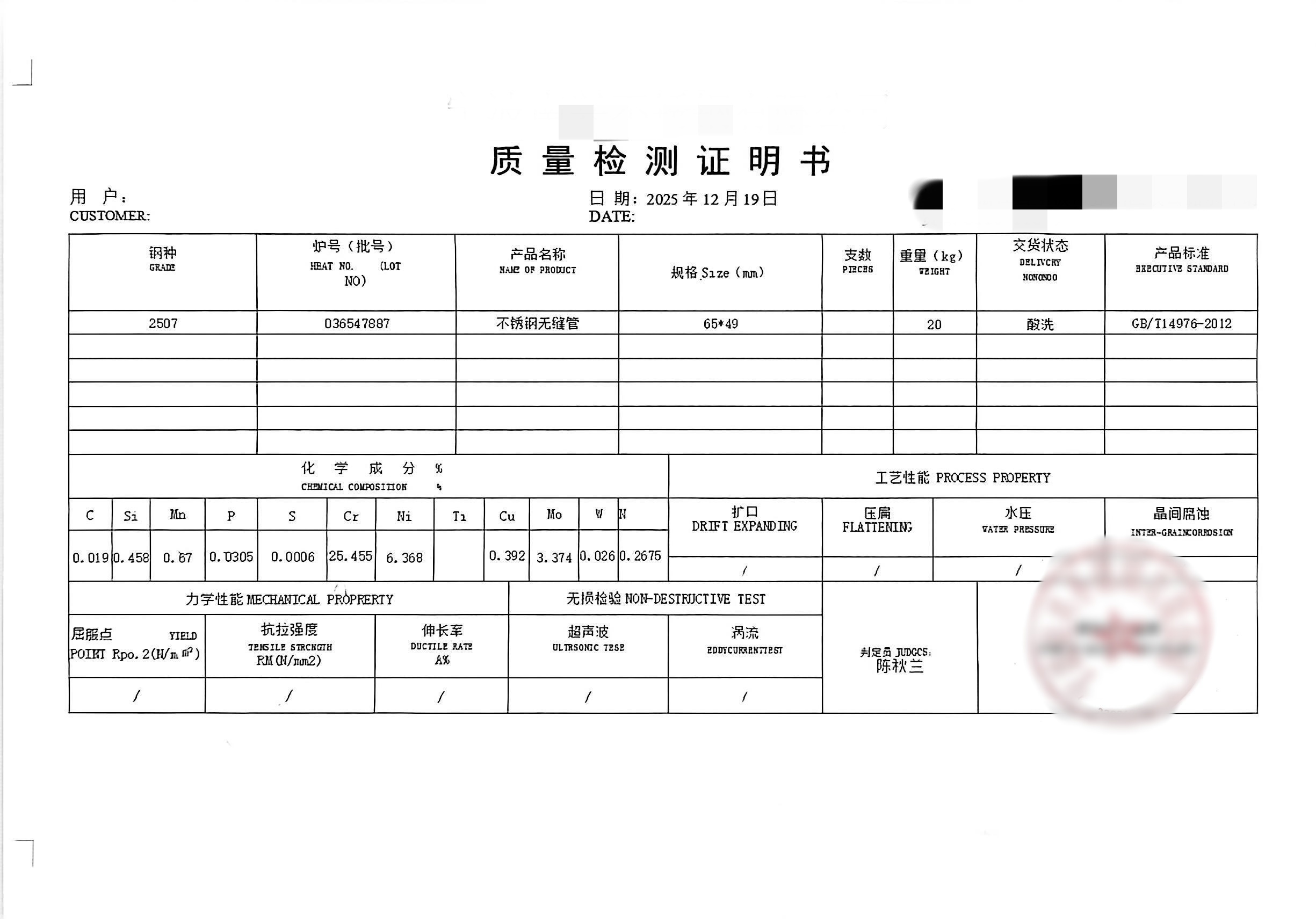

Compared with ordinary 304/316L stainless steel, Duplex 2507 has very strong resistance to corrosion. It can withstand long-term erosion in filtered water without rusting, leaking, or structural failure, ensuring the tightness of the filter system and avoiding secondary pollution of water sources. Below is the material report:

Drawing analysis

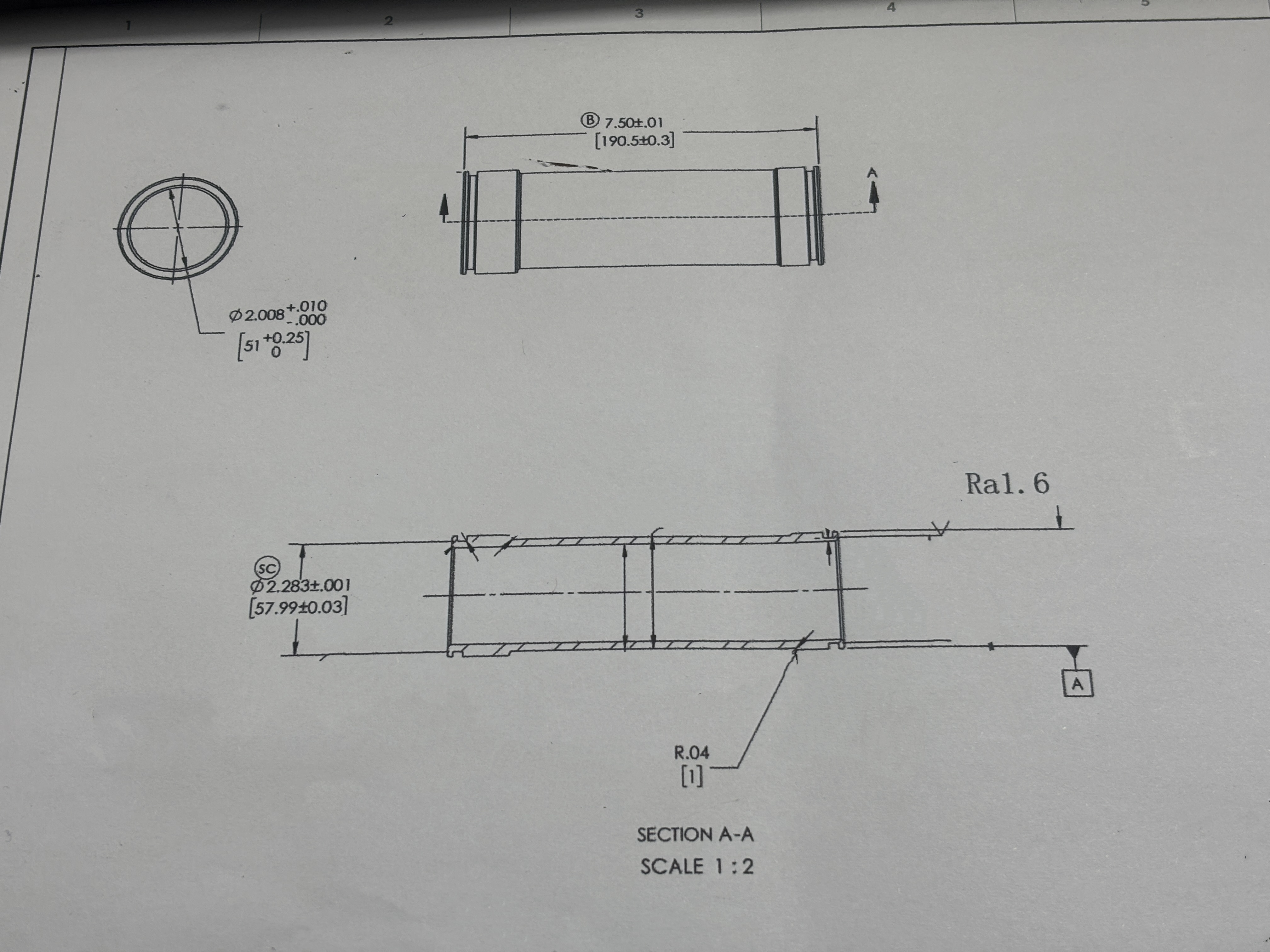

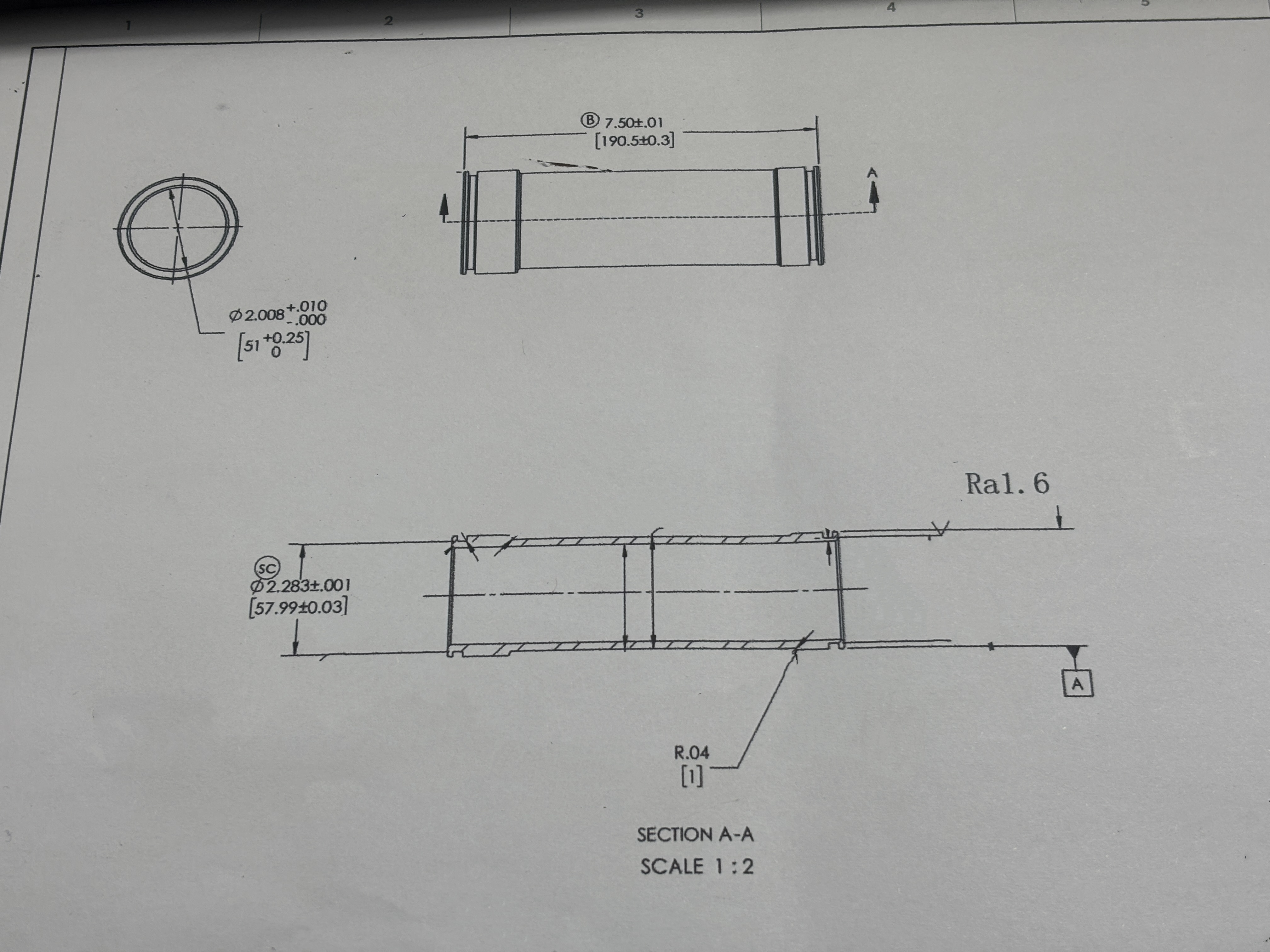

Here is the sketch of the adatper:

This is worked by CNC machining process, and they are made in strict accordance with the drawings. The tolerance is very tight and we work carefully.

Manufacturing Process

The Duplex 2507 adapter is CNC machined directly from the rod material. Belowing is our CNC machining workshop:

After the machining process is completed, the products still need to undergo passivation treatment. This is the finished products:

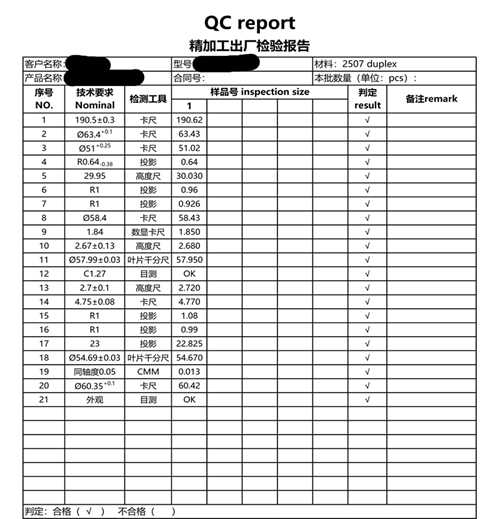

Inspection

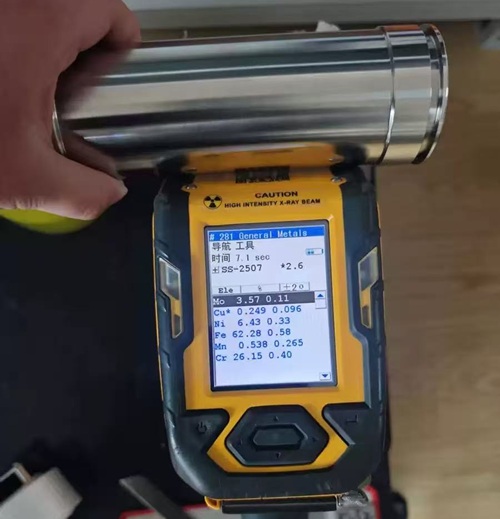

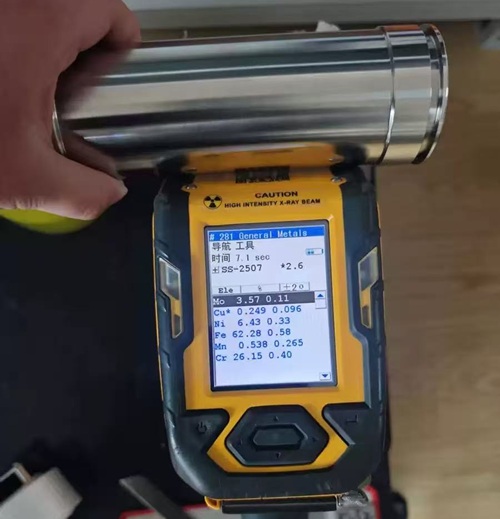

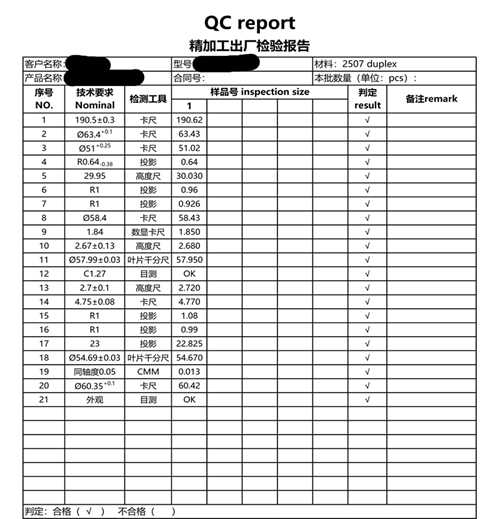

To ensure that every adapter meets the standards, we inspect them before shipment. We conduct full dimension inspection to verify that dimensions are qualified. Carry out roughness inspection to ensure the surface finish meets the requirement for water filter applications. And provide a detailed spectrum report to confirm the authenticity and stability of the Duplex 2507 material composition.

PMI testing

CMM inspection

duplex 2507 inspection report

Packing

After all inspections are passed, we will package each adapter with bubble wrap for shock absorption and then place them in wooden cases. This double packaging protection effectively during transportation, ensuring that the products arrive in perfect condition.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски