Product Introduction

This is a kind of quick coupling made from brass material by CNC machining. Quick couplings are widely available in the market. There are various types, including those made of copper and stainless steel. Our product is brass material. Common applications include automotive systems, air compressors, medical equipment, and irrigation systems, where reliable, efficient fluid and gas transfer is essential.

Material and process

Material introduction

The quick coupling is made from CuZn39Pb3. It is a kind of easy-to-machine brass. It is quite common and its material report is available. Brass offers excellent corrosion resistance, good thermal conductivity, and machinability, making it ideal for couplings in plumbing, hydraulic, pneumatic, or industrial systems. It also provides reliable sealing performance and compatibility with various fluids.

The product is consist of the outer cover, the core, followed by the spring- made of stainless steel, steel balls, snap ring, and O-ring (NBR type).

Drawing analysis

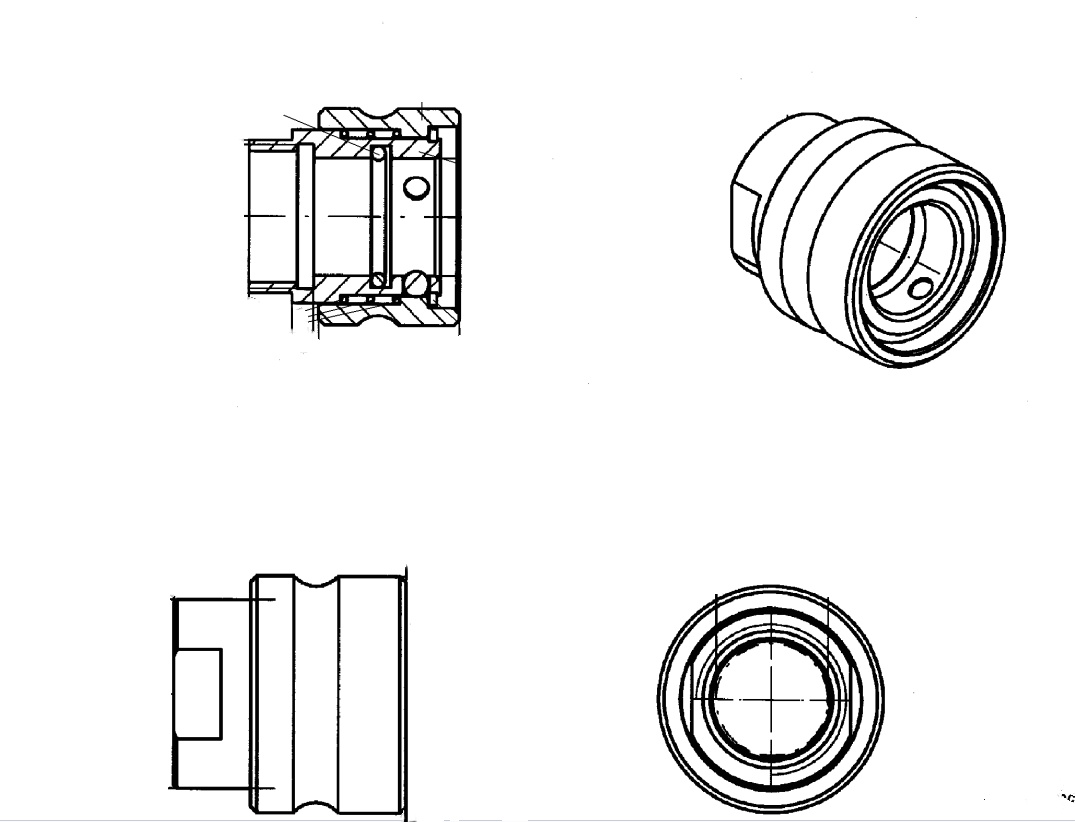

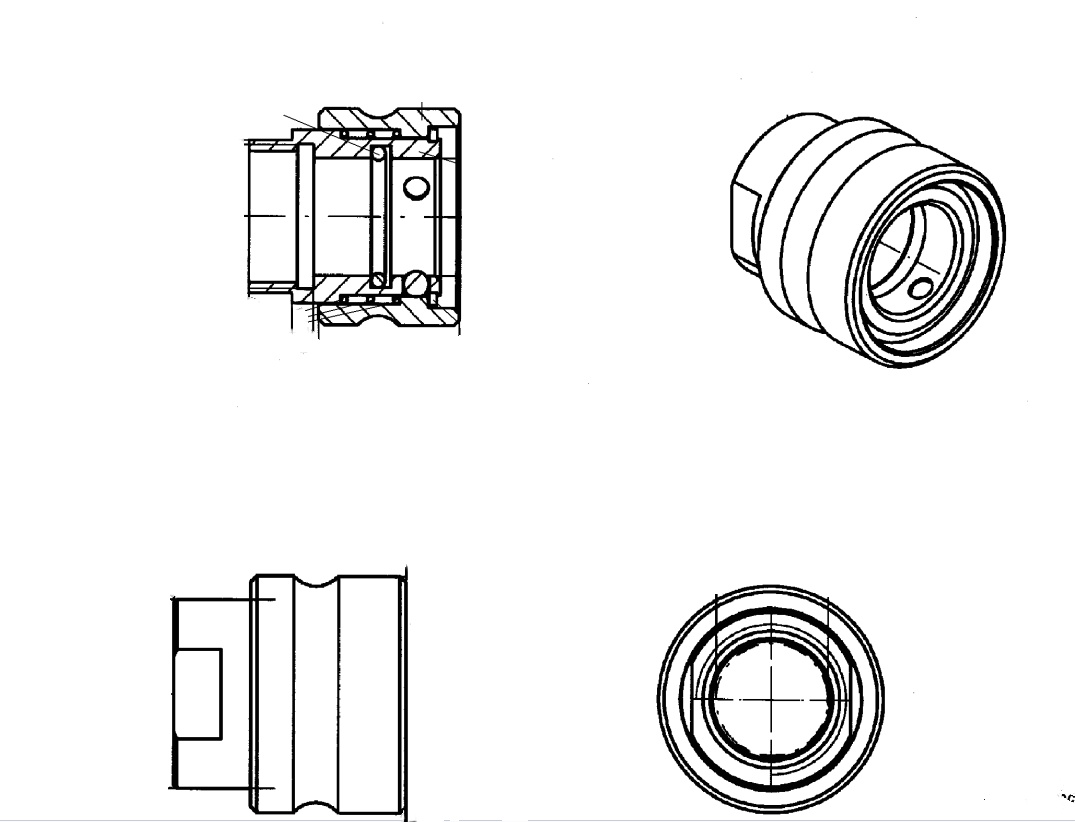

Here is the quick coupling drawings:

The outer cover and the core copper parts were produced by CNC machining. CNC turning enables precise machining of threads, grooves, O-ring seats, and mating surfaces critical for functional integrity.

Manufacturing process

Then we begin to process the quick coupling. The blank is mounted on a CNC lathe, using automated tool changers, the machine performs turning operations—such as facing, OD turning to form the coupling's cylindrical body, and ID boring to shape internal cavities for fluid/gas flow. This step establishes the basic profile, including key features like shoulders or grooves for O-rings. There is knurling on the external surface.

Precision threading is executed using CNC lathe tools or tapping attachments. Both external threads and internal threads are machined to tight tolerances, ensuring compatibility with mating components and leak-free performance.

Inspection

After production finishing, we couduct inspection of the quick coupling. Randomly select several products for inspection, measuring their dimensions and threads. Here are our tools to inspect:

Packing

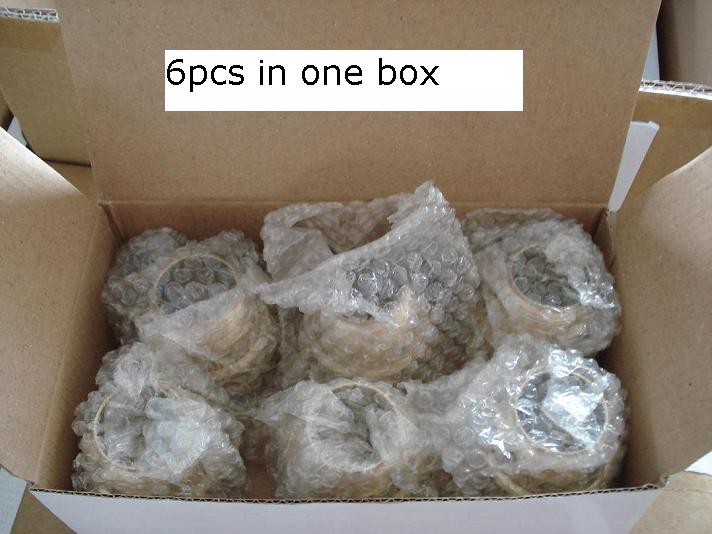

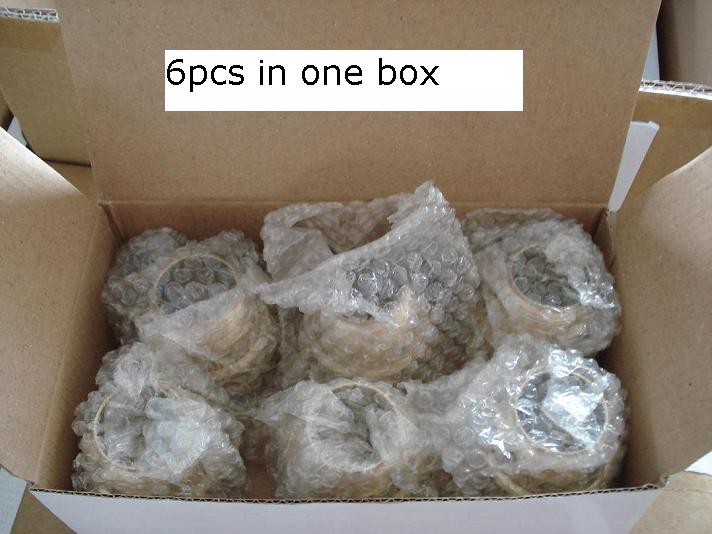

The qualified quick couplings were put in bubble bags to protect the parts when we finished checking, then packed in cartons.

The cartons were laid on the pallets and fixed with film and strip to avoid carton scattering.

Ningbo Joyou Metal Products Co., Ltd is a professional OEM metal parts supplier, specialized in CNC machining, die casting, investment casting and other manufacturing process.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски