Product Introduction

This is a regular part, which is made from aluminum material by die casting process, used in furniture industry. Premium-grade aluminum alloy known for their excellent corrosion resistance, thermal conductivity, and machinability is used, ideal for applications requiring robust, lightweight.

Material and process

Material advantage

It's made from aluminum material by die casting process. Aluminum's strength-to-weight ratio minimizes installation effort without compromising performance. Aluminum is soft and easy to cut, drill, or form, allowing for precise machining of intricate shapes with lower tool wear and faster production cycles.They reduce the load on door and window frames, especially suitable for lightweight frames, preventing frame deformation caused by heavy components over long-term use.

Manufacturing process

This is a project for a Ukrainian client. We first conducted an analysis and research after receiving the drawings. Then we decided to use the die casting process to manufacture this striker plate.

Molds are typically made from high-grade tool steels H13, chosen for its heat resistance, hardness, and wear resistance, critical properties, as molds endure repeated exposure to high temperatures and high injection pressures.

The selected steel blocks undergo rough machining to shape the basic mold structure. Processes like milling, turning, or grinding remove excess material, creating the mold base and preliminary features. This stage focuses on achieving approximate dimensions, leaving a small machining allowance for finishing.

The cavity and core are machined with extreme precision. Advanced techniques like EDM, wire EDM are used here,

EDM uses electrical sparks to erode metal, ideal for intricate details, sharp corners, or hard-to-reach areas that traditional cutting tools can't access, wire EDM cuts precise shapes with a thin, electrically charged wire, ensuring straightness and accuracy for slots or thin walls.

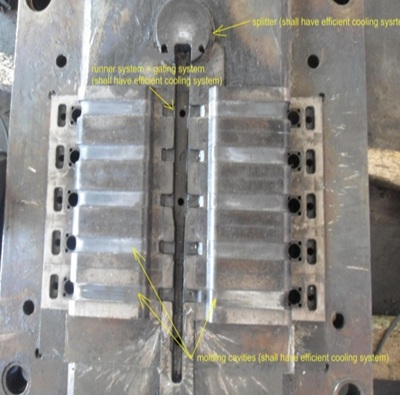

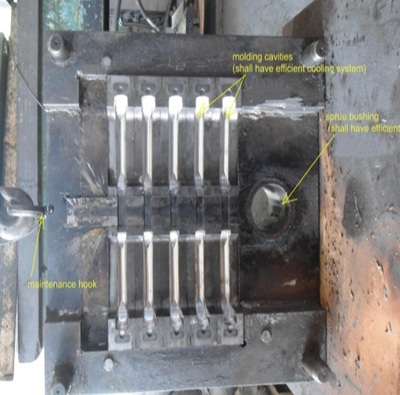

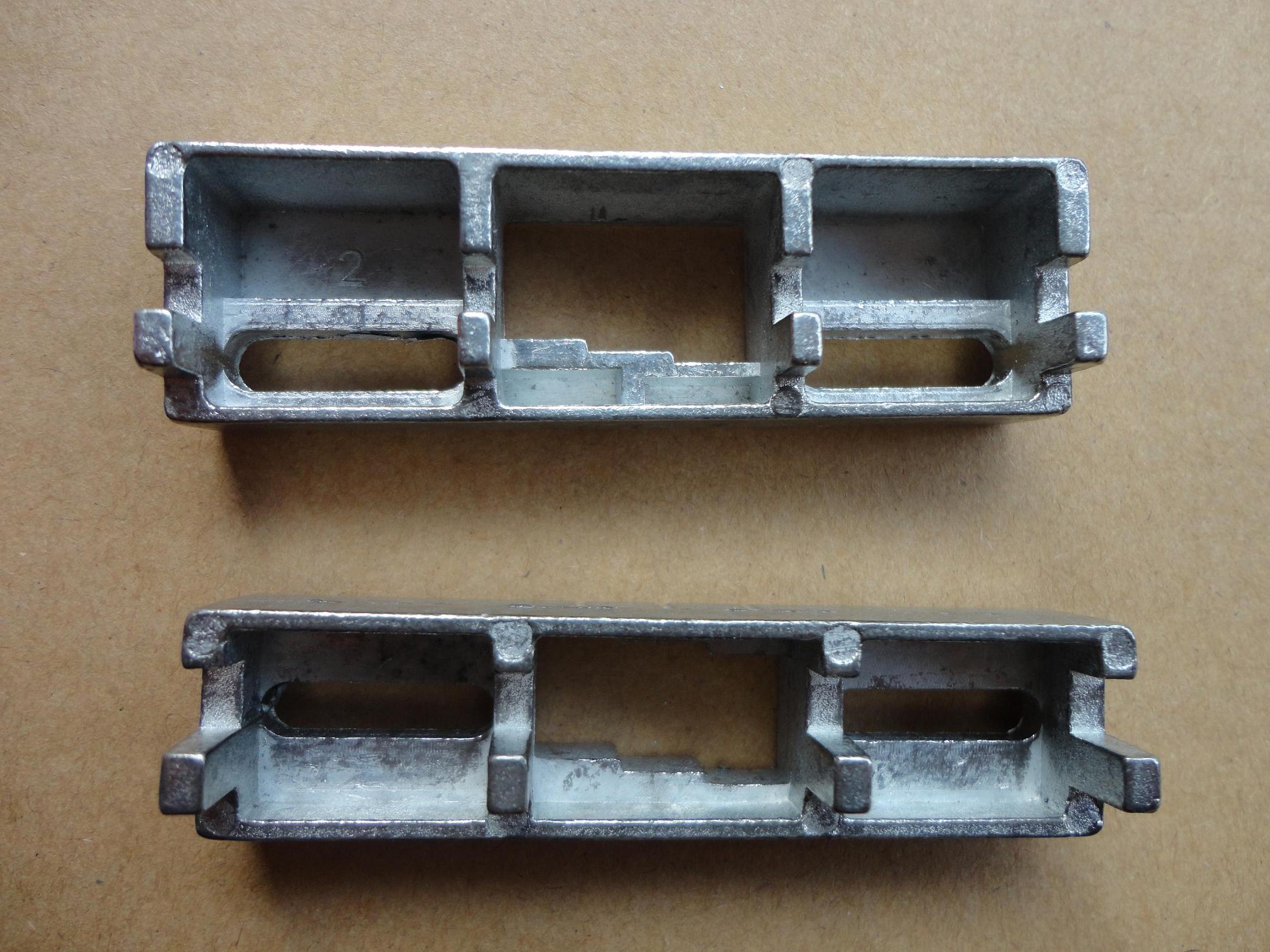

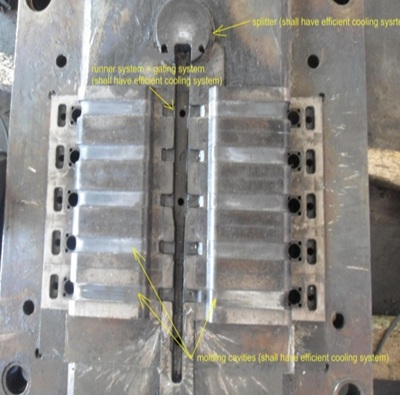

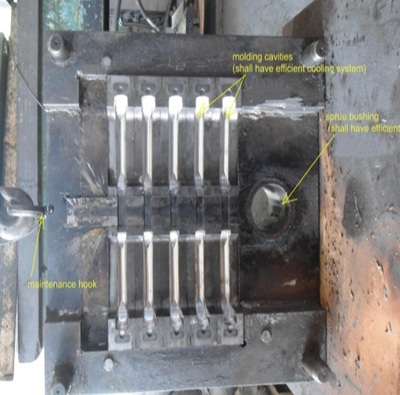

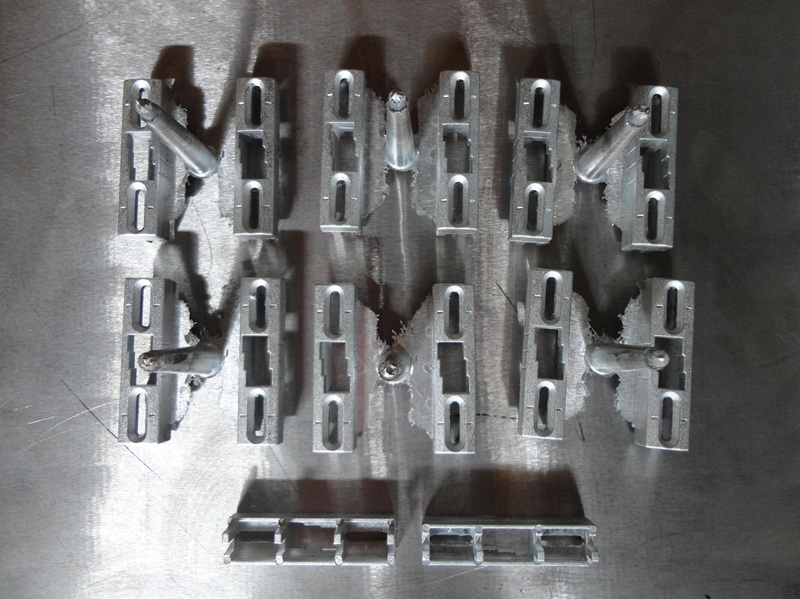

Here are the mold pictures:

gating system splitter

sprue bushing hook

the plate mold

The moving die is driven toward the fixed die, clamping them tightly together. The molten aluminum is injected into steel dies under high pressure, ensuring rapid solidification and fine detail reproduction. A hydraulically driven plunger then forces the molten metal through the runners and gates at high speed, filling the die cavity completely. This rapid injection ensures the metal takes the shape of the cavity before it starts to solidify, capturing even intricate details like thin walls or fine textures.

Once the cavity is filled, the molten metal cools and solidifies inside the die, which is designed with internal cooling channels to accelerate this process, after the metal has fully solidified, the clamping force is released, and the moving die pulls away from the fixed die. Ejector pins then push the solidified part out of the cavity.

Post treatment

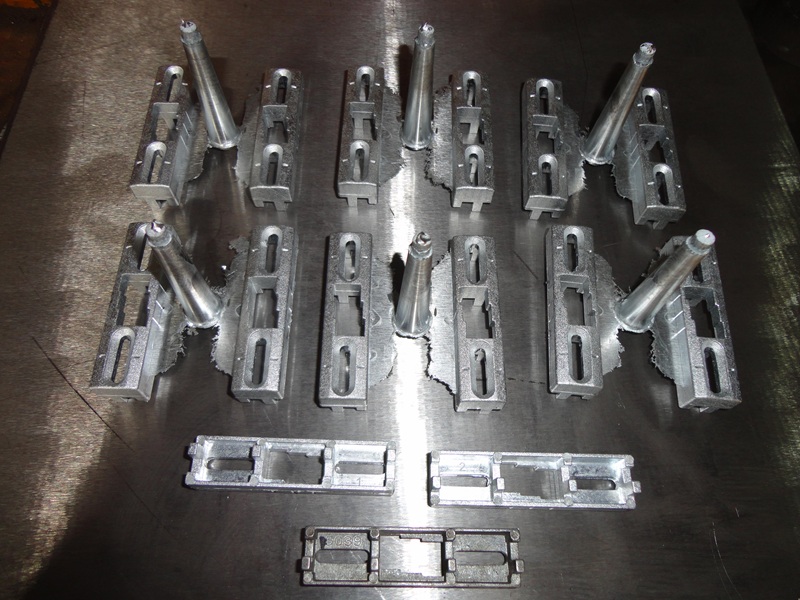

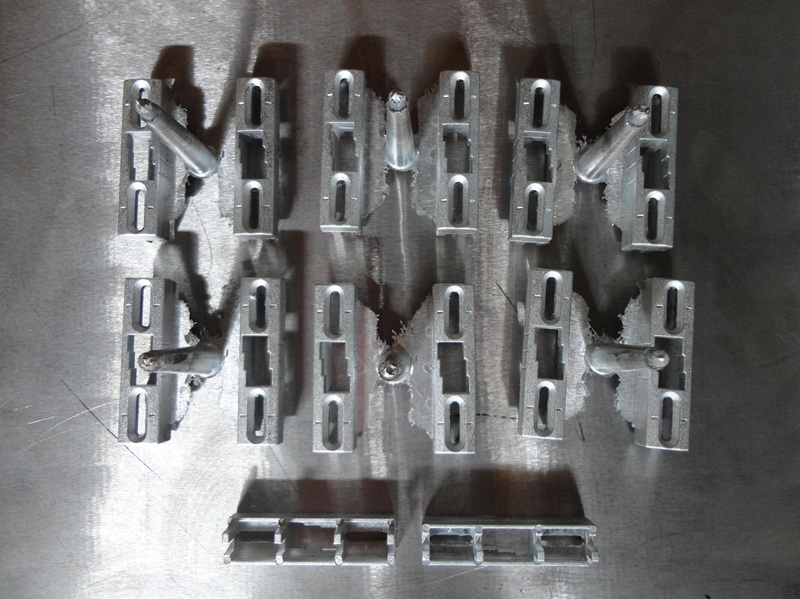

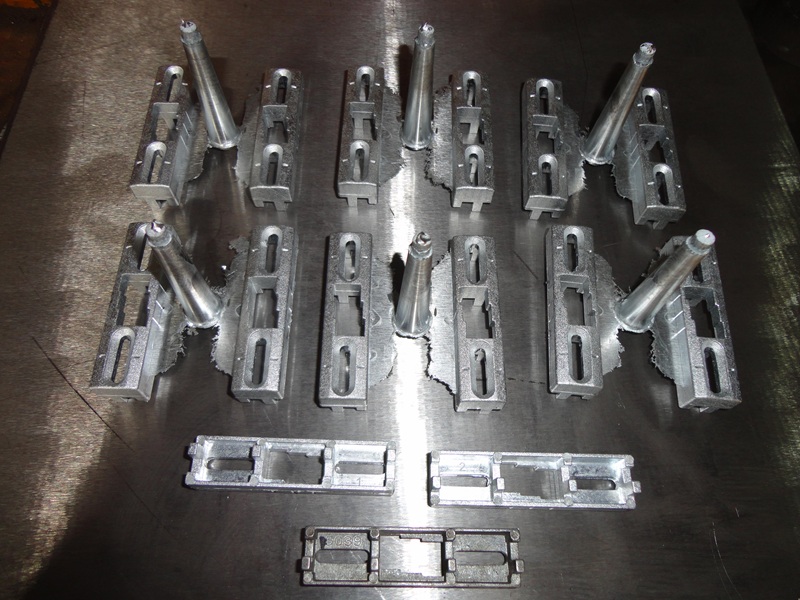

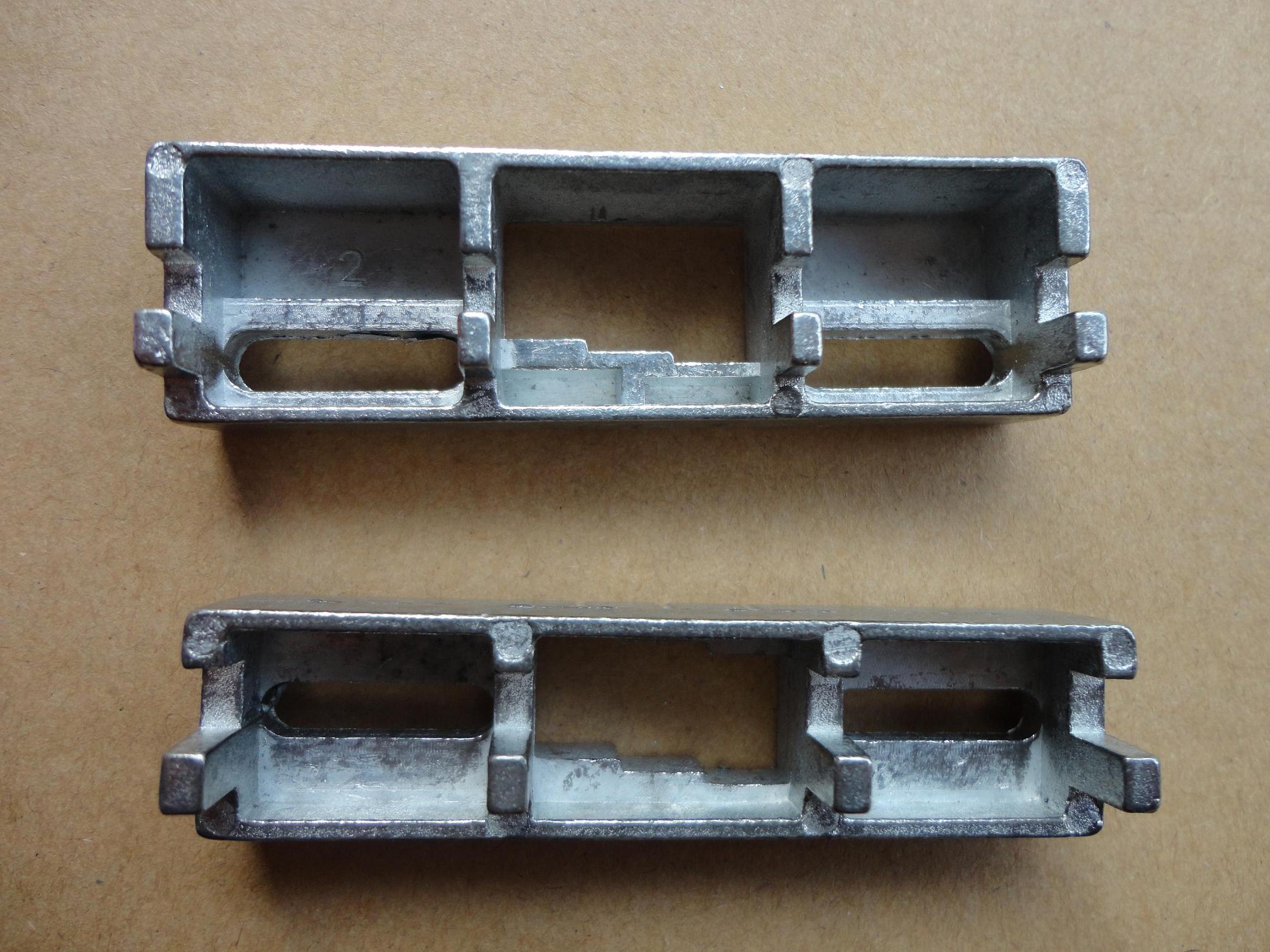

Here are the rough striker plate castings:

rough castings-1

rough castings-2

After that, remove excess material like sprue, runners, or flash by using cutting tools or presses.

Then they are sent for sand blasted. Here is the finished striker plate:

Packing

After the products are completed checking, each unit is individually packaged in a plastic bag. This primary wrapping serves as a basic barrier against dust, moisture, and minor scratches, ensuring the surface of each product remains clean and unblemished before further handling.

Once individually bagged, the products are carefully placed into sturdy wooden crates. These crates are constructed to provide robust structural support, with their solid frame designed to withstand the rigors of transportation.

Ningbo Joyo Metal Products Co.,Ltd. expertise spans diverse metalworking processes, including CNC turning, milling, drilling, grinding, forging, and die casting, allowing us to handle various materials such as stainless steel, carbon steel, aluminum alloys, brass, and copper. Whether it’s intricate parts like precision shafts, threaded fasteners, or custom brackets, or larger components such as metal frames or structural fittings, we ensure consistent quality through strict dimensional checks, material testing, and surface finish inspections.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски