Product Introduction

This handle is used on furniture. Its main function is to adjust the height of the furniture legs to meet the needs of different users. The customer's initial design used a normal thread. After our suggestion, they agreed to use a trapezoidal thread, which would greatly improve the efficiency of height adjustment.

Material and process

Lightweighting is also a direction in the development of furniture. Naturally, using aluminum alloy as the material is both lightweight and easy to process. It's made from 6061-T6 material by CNC turning process.

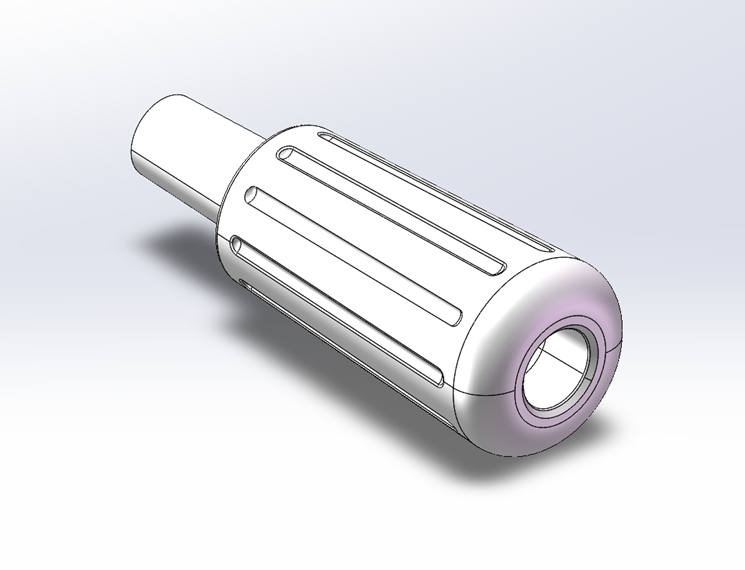

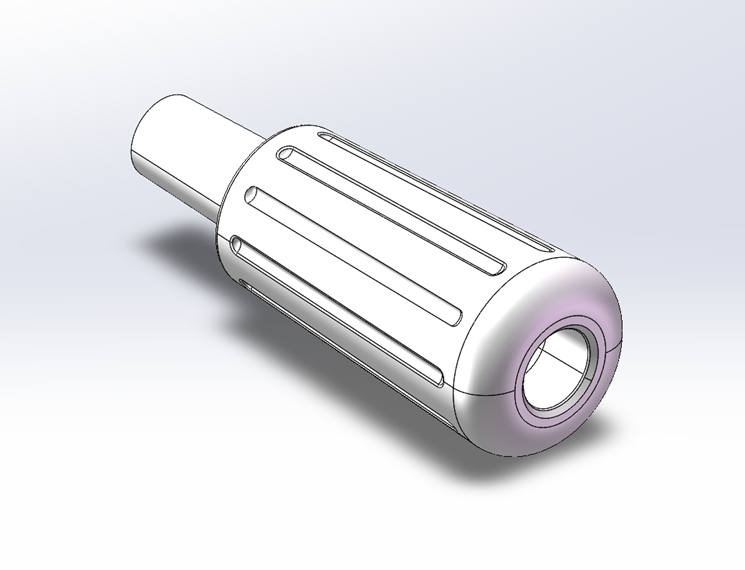

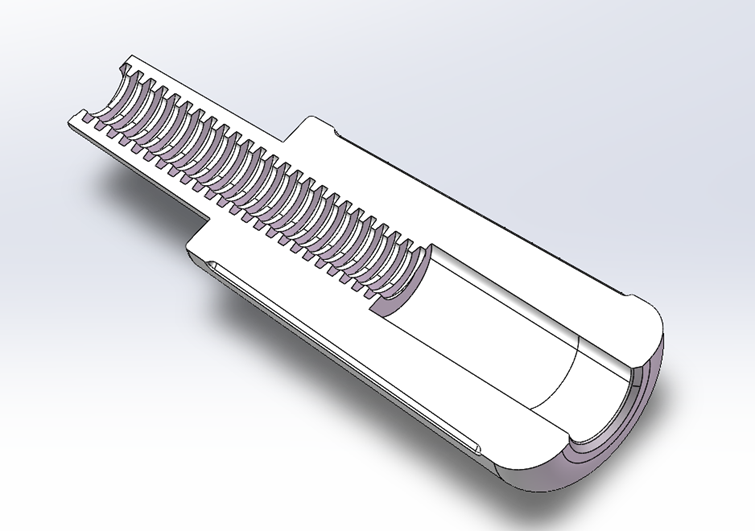

Here is the initial 3D design:

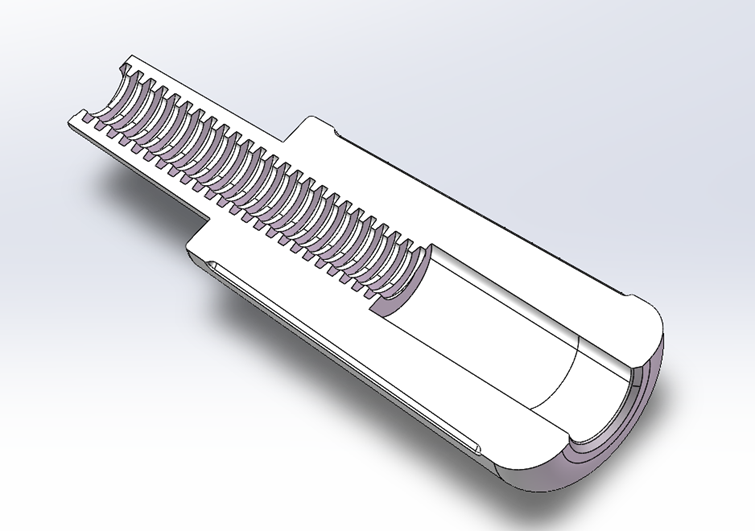

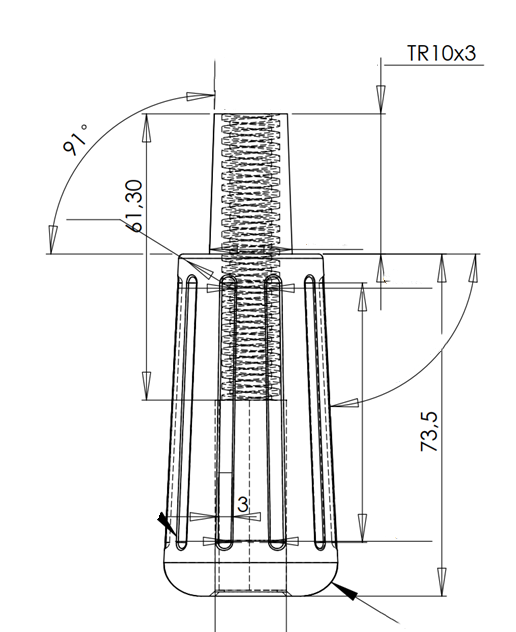

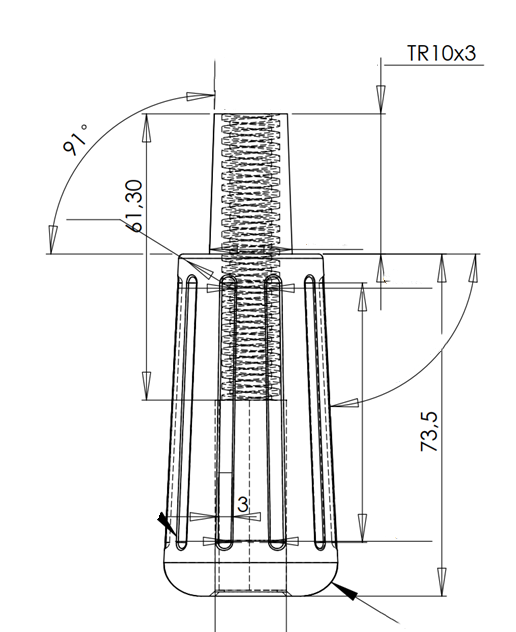

This is the improved drawing:

The overall handle is of a conical structure. You can see 91° on the drawing. In addition, the trapezoidal thread specification is TR10x3, and its length is also relatively long, 61.30mm.

Trapezoidal threads are a special type of thread with an isosceles trapezoidal cross section. Trapezoidal threads are widely used in mechanical equipment due to their good transmission efficiency and high strength, especially in situations where precise transmission is required. They are often used in cranes, pressure machinery and various automation equipment.

We originally used bars with an outer diameter of 40mm, and each one was roughly cut into 105mm long. The outer shape was directly processed by CNC turning. The smaller part was turned first. Then it was re-clamped to CNC turn the larger part. The cutting tool used was a gem cutter. This type of cutter tool is particularly suitable for processing aluminum alloys. The surface is uniform and delicate, very beautiful.

Then there are 8 grooves with a width of 3mm and a length of 55.5mm, CNC turning cannot process this, CNC milling is the suitable for processing these. There is a long hole in the middle, which is really long. We chose the process of drilling holes at both ends and combining them in the middle, and then used a TR10x3 tap to process the trapezoidal thread.

Here is the picture of the taps :

Finally the rough handle is finished:

The bolt used in conjunction with it, a whole 200mm long screw of TR10x3, is processed by rolling.

Below is the assembly picture:

Surface finish

The handles are sandblasted and black anodized, then they are completed.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски