Product Introduction

50 thousands of brass knobs and stainless steel knobs are placed by our customers, which used in small furniture , like drawer or else, made by CNC turning process.

It is tiny and shine items with uniform color, pretty beautiful and people love that.

Material and process

Material introduction

Stainless steel in grade SS303 or 1.4305 and brass in Cu39Pb3, both these two material are good, their features making them suitable for moist environments, easy-to-maintain surface requiring minimal cleaning effort, and great versatility in styles, shapes, and sizes for different furniture types.

Process

This kind of material is easy cutting, very suitable to work on Swiss Automatic Machine. The machine also known as a Swiss-type Lathe or Swiss Screw Machine is a highly specialized CNC lathe designed for precision machining of small, complex, and slender components. Originating from Switzerland's watchmaking industry, it has evolved into a critical tool for modern high-precision manufacturing. Its unique design distinguishes it from conventional CNC lathes, making it indispensable in sectors demanding micron-level accuracy.

The video is machining the drawer knob

Surface finish

Polishing gives them a great finish for both stainless steel and brass. If we add a chrome plating, they shine even brighter and the finish holds up better. Basically, polishing makes them look sleek, but chroming is like adding an extra layer of durability and bling. It's a simple way to make sure they stay shiny with daily use.

Inspection

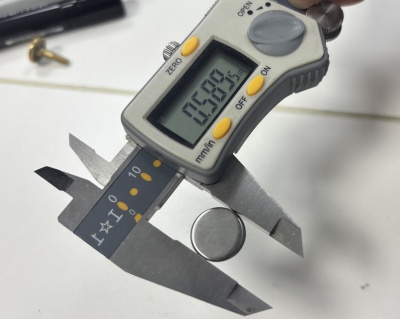

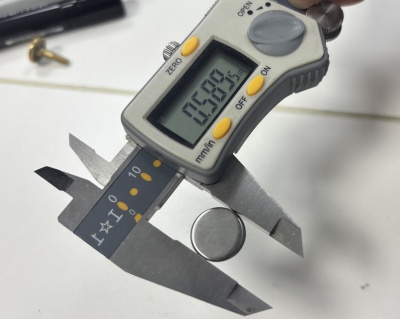

We measure all the dimensions to make sure they're qualified, and inspect surface to check if it meets standards.

For dimensions, we use calipers to check things like diameter, length. The OD of the knob is 0.59 inch, and length is 0.72'', thread is M5, weight only 4g. As for the surface, we look under bright lights for scratches, dents. If a knob has a chrome finish, we make sure there's no peeling or discoloration. It's all about catching any little issue before the shipment.

Packing

Even though the products are small, we still take extra care with each one with packaging. Each knob gets wrapped in a soft anti-static cloth first, then a layer of bubble wrap. The cloth keeps away tiny dust particles that could scratch, and the bubble wrap cushions them from bumps. Then put them in boxes and packed on the pallet which wrapped with protected film.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски