Product Introduction

They are made by the aluminum extrusion process, these racks can be shaped into a wide range of profiles, from sleek, minimalist frames to reinforced structures with built-in slots or grooves, they are used to hold things like bowls and plates.

Material and process

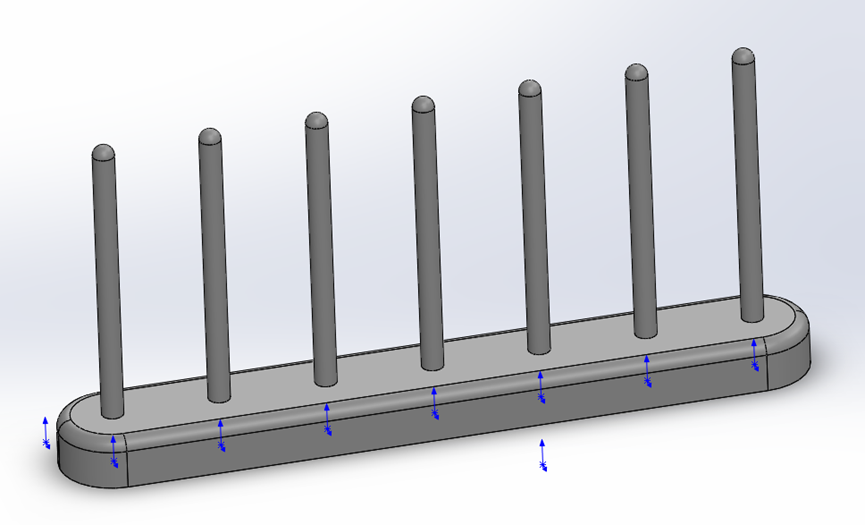

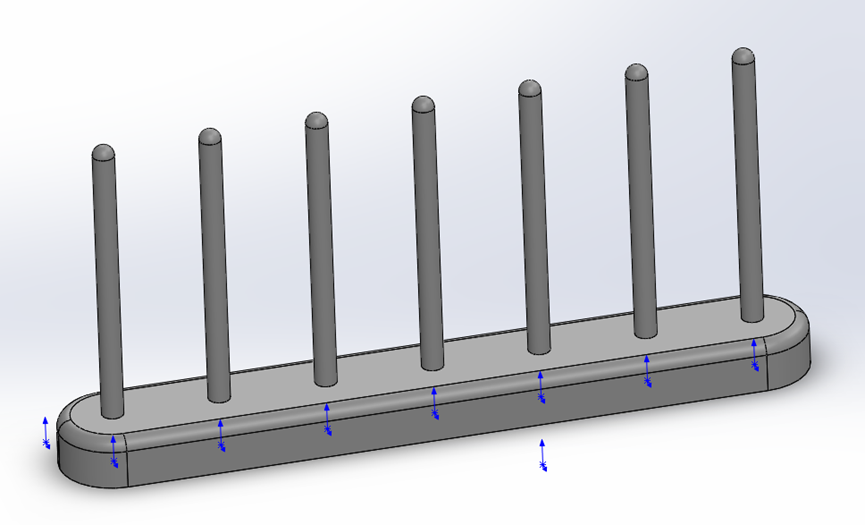

They are made from aluminum material by extrusion process. Here is the initial design drawing:

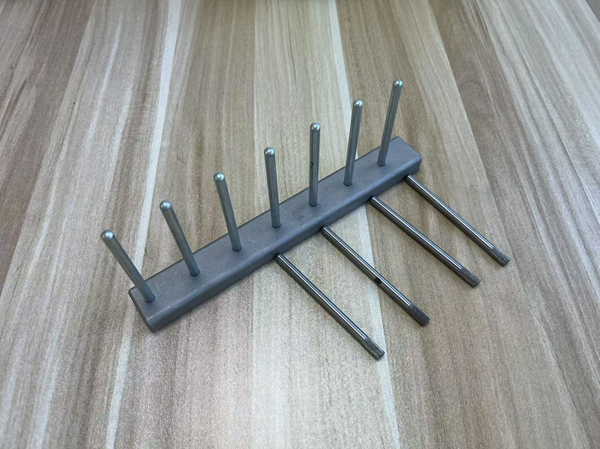

The first thought is combined the aluminum base with steel pins inserted, then black powder coated.

The base is made by CNC milling, seven holes are tapped, the arcs R=12.5 at both ends and R=3 around all need to be milled. The bottom of the steel pin is also threaded in M5 and screwed in the bottom, each pin must be of the same height.

It is found that the cost of making the base in this way is too high. Assembling the threads in this way is very inefficient.

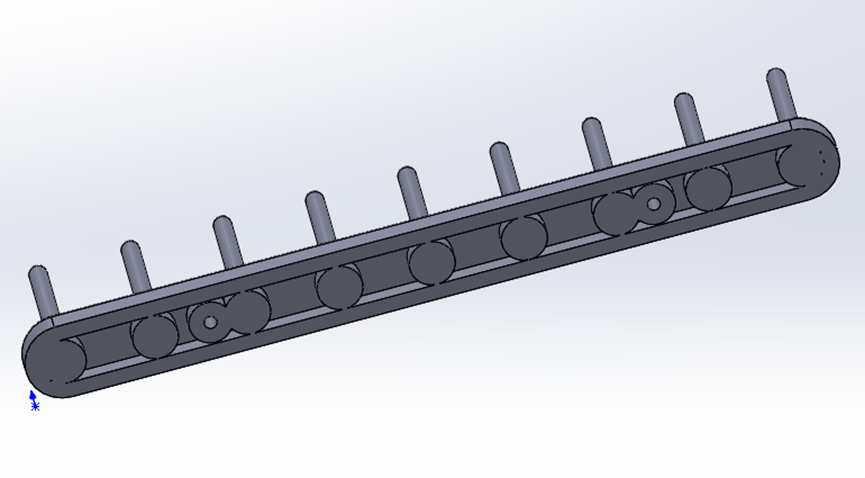

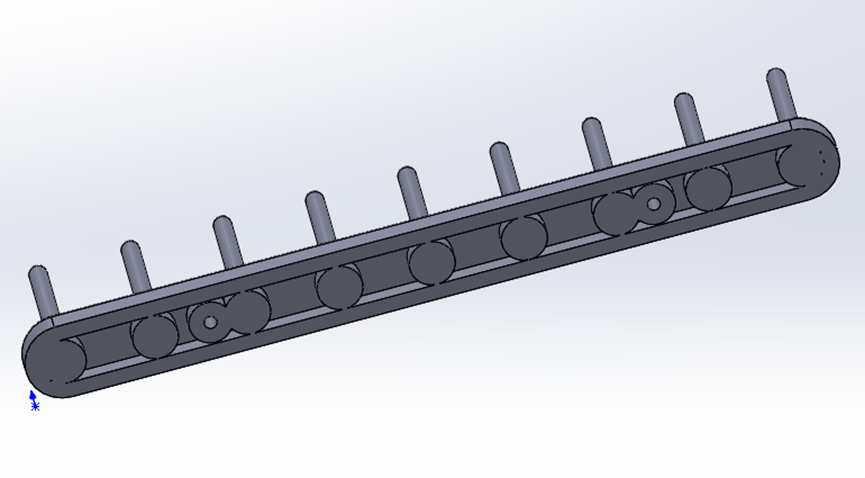

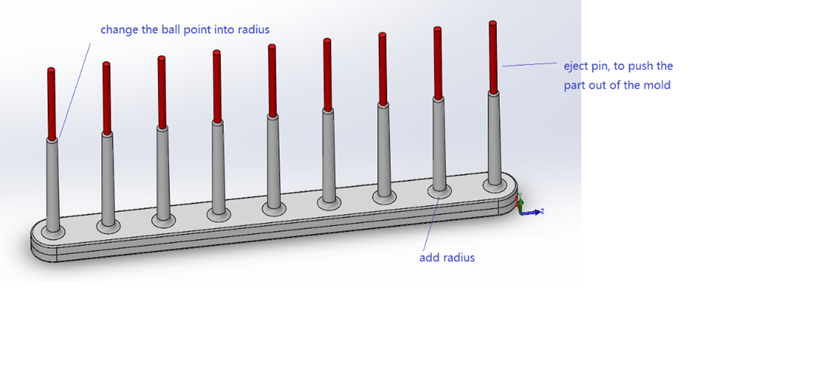

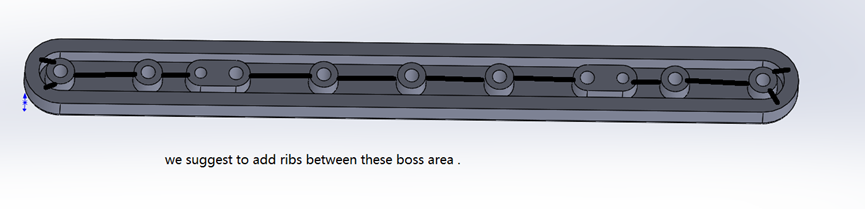

Then we begin to research plan B and come out the drawings, the overall rack will be made by die casting process.

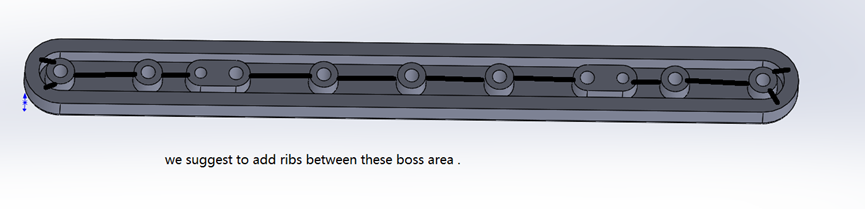

The bottom has been hollowed out and reinforced with ribs. It not only ensures strength but also saves materials.

Then discussed with customer, finally this plan was rejected because the mold cost is too high and the customer also worried that using aluminum alloy to make these pins may not be strong enough, so we gave up this second option.

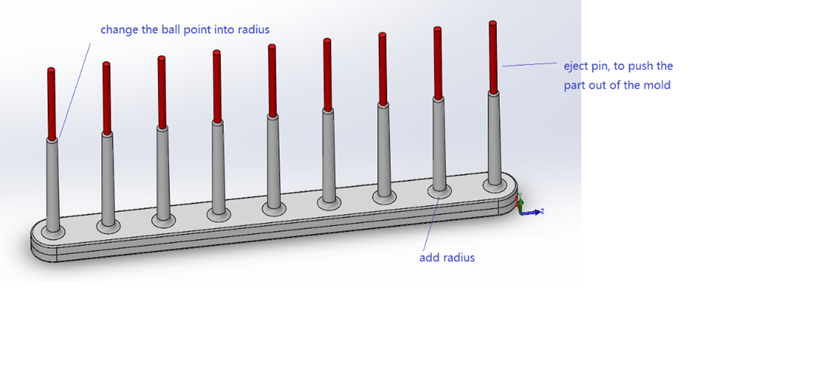

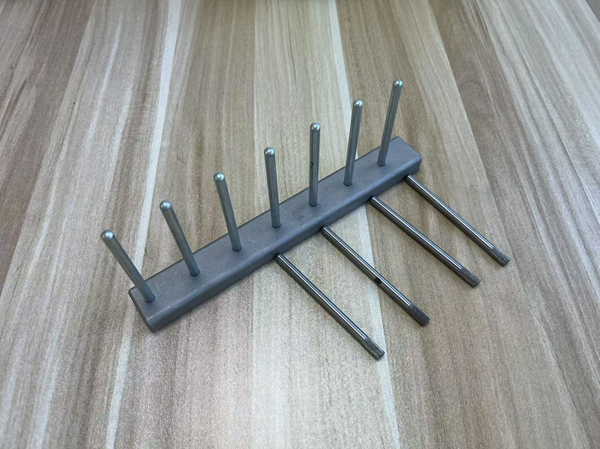

Finally, we came up with the most suitable solution. The bottom of the rack will be made from solid aluminum extrusion profile, then play seven holes. There will be an R angle at the head of solid pins.

At the bottom, it is in a knurled pattern, no threads anymore. Then directly inserting the 7 pins into the holes, press them down with a press. Due to the presence of knurling, it will adhere tightly to the material. This is a very economical and very simple design.

This plan get approved ultimately and proceed, check our from the below picture:

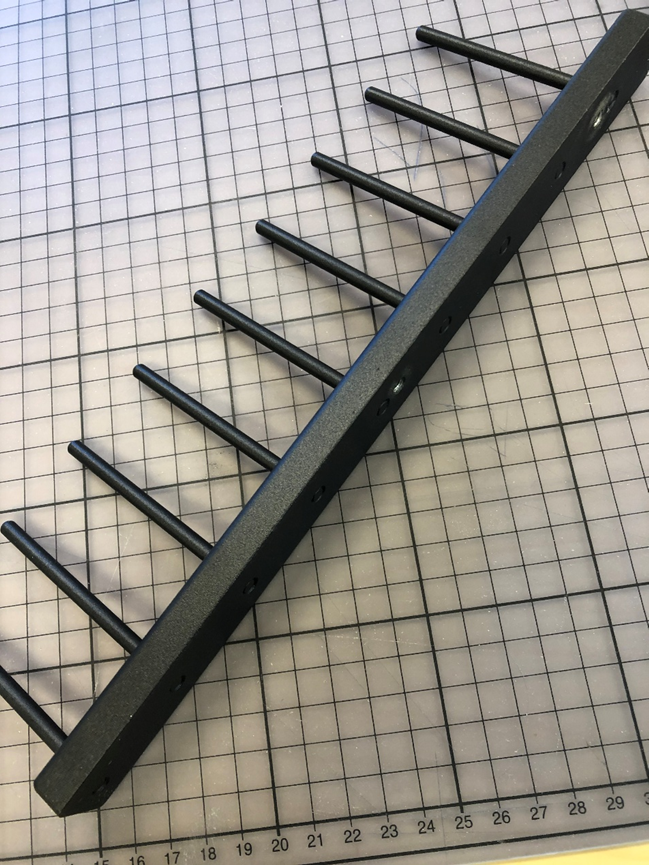

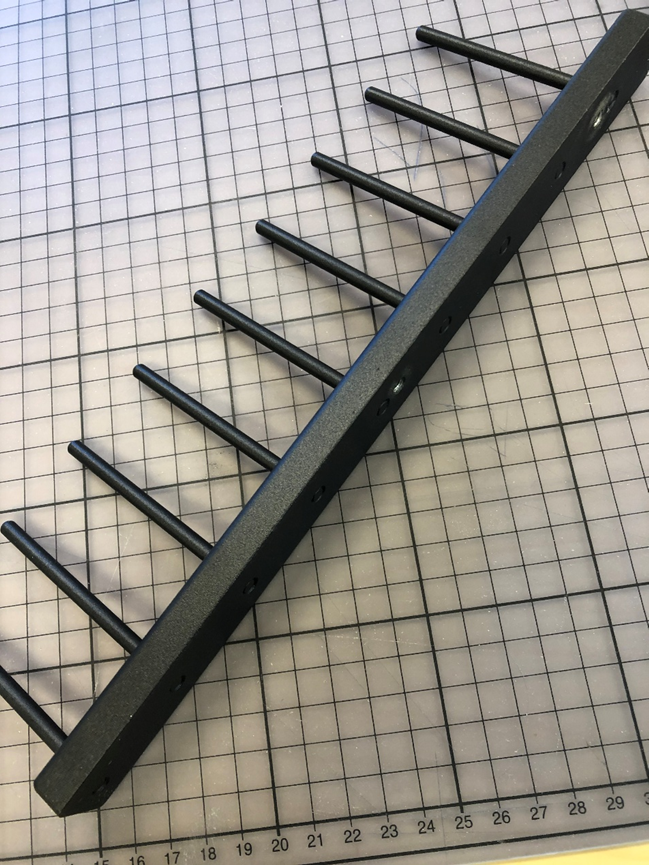

Below picture is the black rack with black powder coated surface:

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски