Product Introduction

This shiny stainless steel handle ring is designed to insert closet. It's easy to install, use, and clean, making it a popular choice for furniture closets.

Material and process

Material introduction

To keep the surface bright and rust-free for a long time, stainless steel 304 is a great material for handle rings. And to save costs, using seamless stainless steel tubes is the best way to make them.

Manufacturing process

Correct size of stainless steel tube was purchase and delivered by material supplier and cut into pieces in our workshop by sawing with correct length. Check out the pictures below.

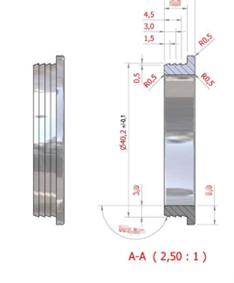

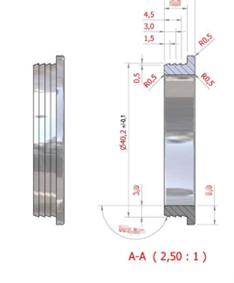

After that, each piece is loaded into CNC machines for further processing. Please refer to the following drawings and images for details.

As shown, the outer insertion area features three beveled steps, this excellent design make worker easy to inset into closet.

The ring has strict visual surface requirements, specifically needing to be free of cutting marks. To achieve a smooth and attractive surface, our engineers set the CNC machine's rotation speed at 1200 revolutions per minute (rpm).

Packing

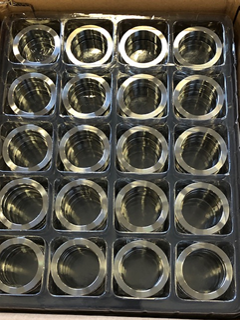

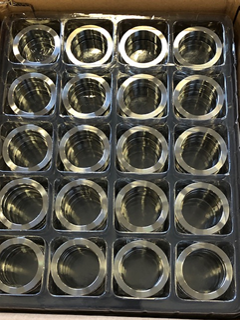

To safeguard the visual surface and prevent any transportation-induced defects, using plastic trays is an ideal protective solution for these handle rings. Please refer to the images for illustration.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски