Product Introduction

This is a kind of decorative cover made from 304 stainless steel by CNC machining process. It is used on furniture, the product has very high requirements for the surface, the slightest defect is unacceptable. This component combines 304 stainless steel's robustness with CNC machining's precision, delivering a both visually appealing and long-lasting decorative solution.

Material and process

The material of this decorative cover is 304 stainless steel 10mm thick square bars. 304 stainless steel is chosen for its exceptional corrosion resistance, durability, and sleek finish, ideal for decorative applications. It withstands environmental factors like moisture, oxidation, and temperature variations, ensuring long-term performance in indoor or outdoor settings.

The square rod need to be cut into pieces first, the freshly cut square pieces are rough on the surface and has sharp corners.

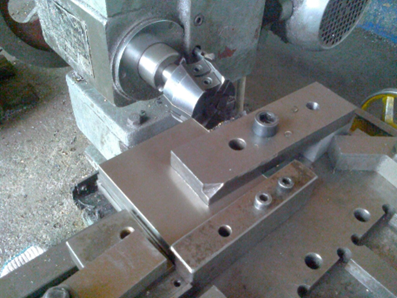

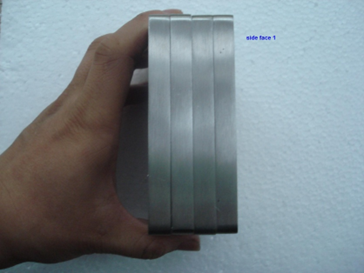

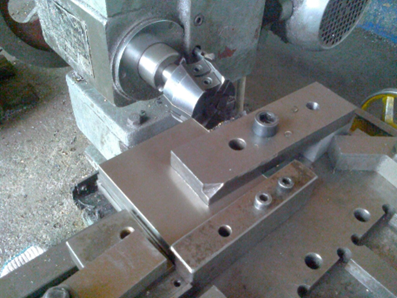

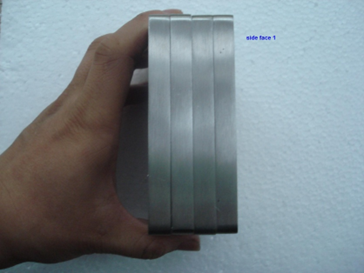

Then take the square pieces and mill its four sides to ensure that all four sides are flat.

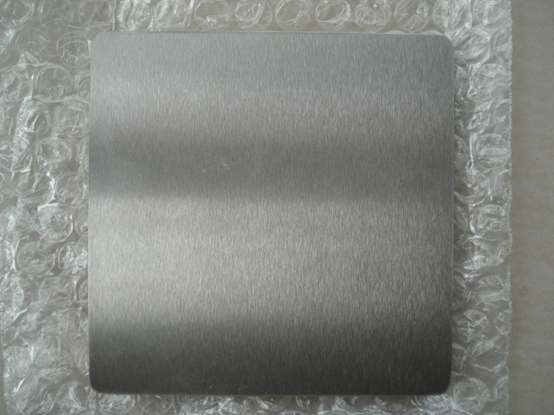

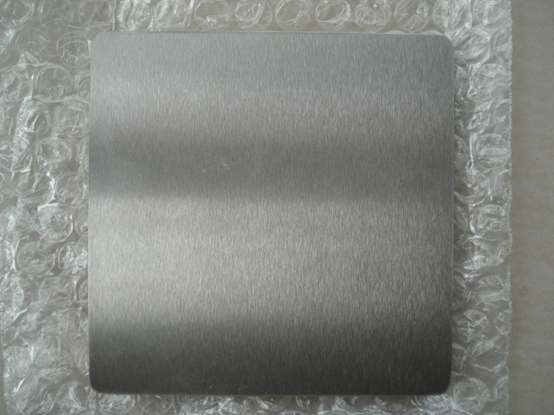

After that, we move forward to mill the whole backside surface.

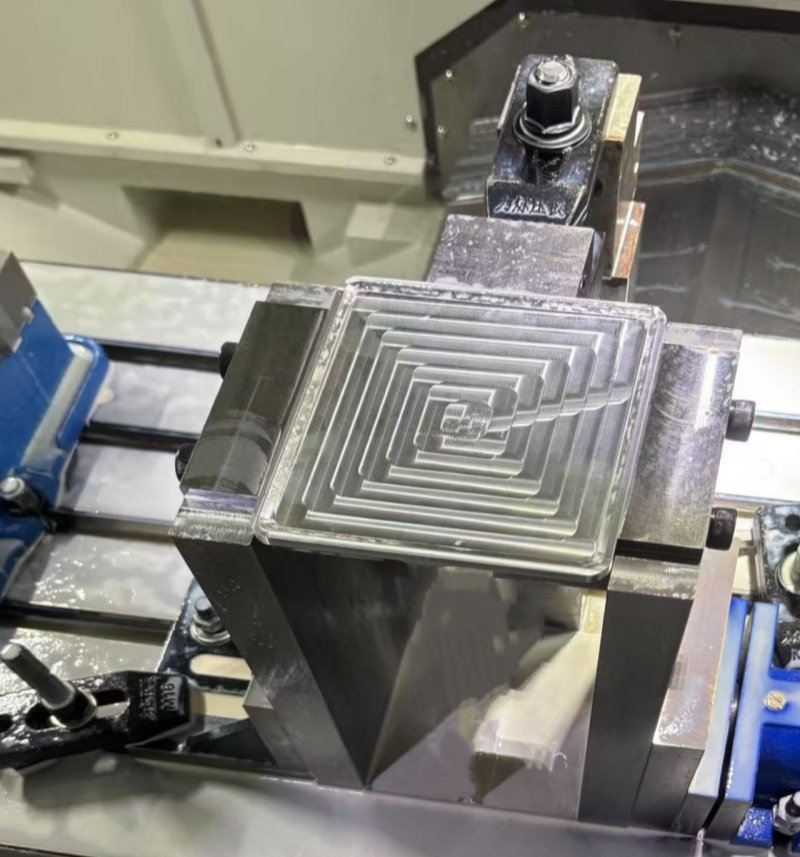

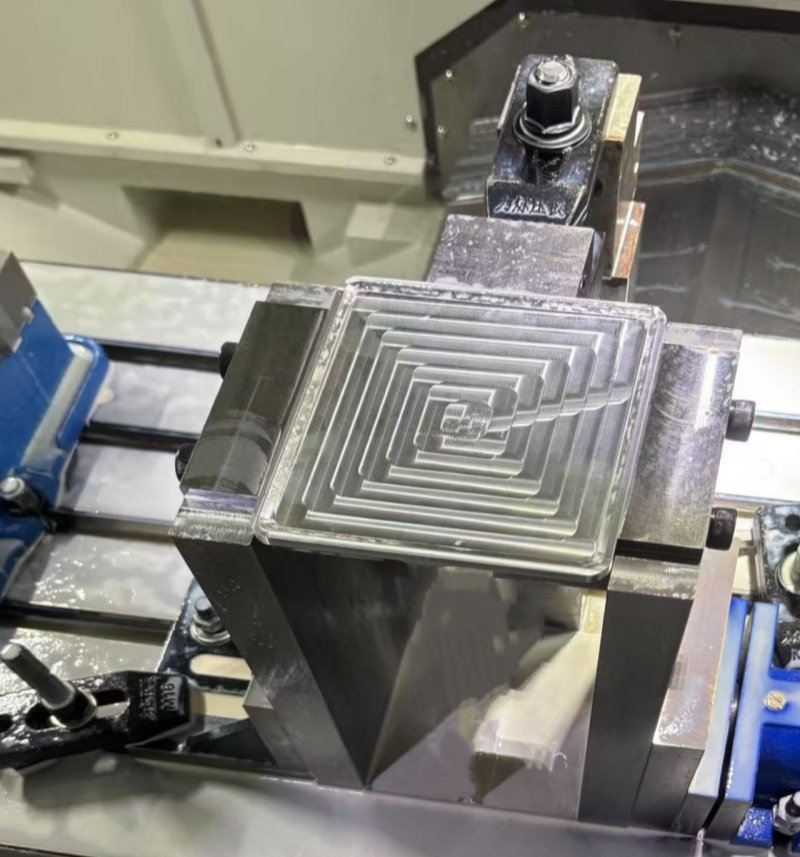

Here is the picture of the surface:

It is normal that the marks left by the tool pass are very obvious. Then drill the thread of M4, with a depth of 4-5mm. It is very difficult to drill small threads in stainless steel products, because it is very easy for the tap to break inside, which can lead to the scrapping of the entire product. Inside thread cannot have grease, etc., need to be thoroughly cleaned with ultrasonic waves.

For the side surface, need to be polished and brushed, each surface needs to be uniform, with consistent depth and color of the patterns.

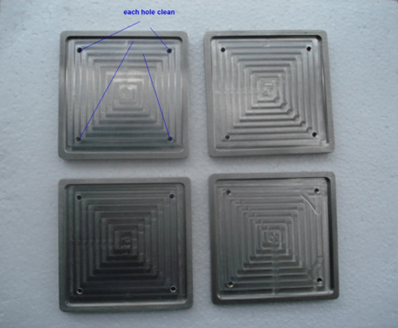

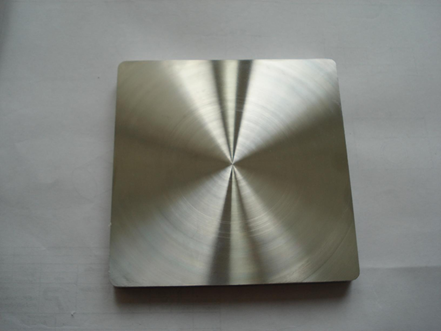

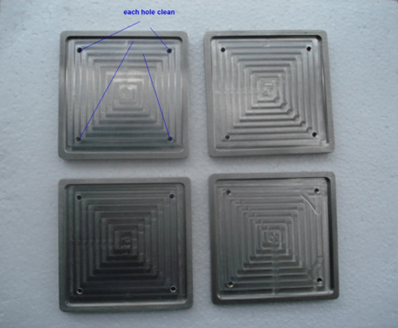

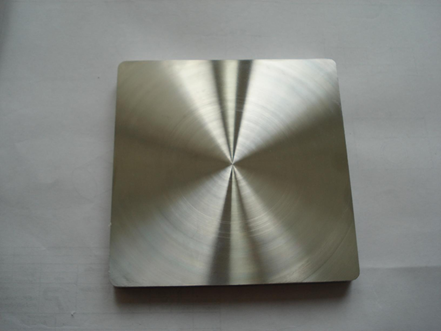

For the visible surface, the customer wants to do two kinds, one is CD pattern, which is very bright.

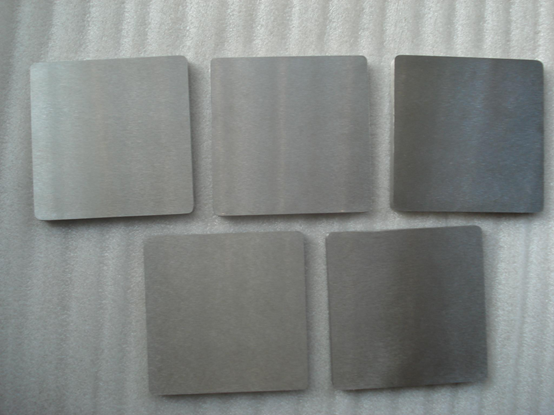

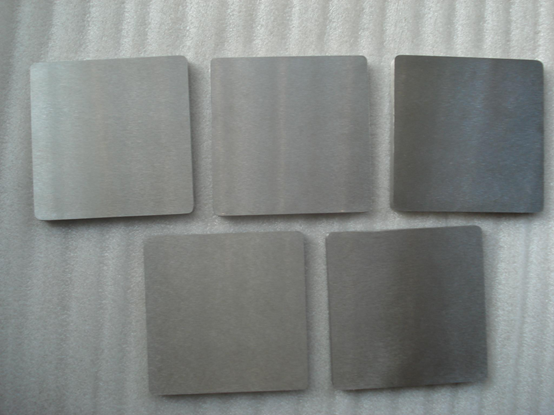

Another type has a surface grinding on the outside, and its color is similar to the brushed texture on the side. The product has a very good texture and uniform color.

Packing

The entire product is not allowed to have any burrs, scratches or other flaws. It is an artistic decorative cover. So we conduct a comeprehensive inspection of the surface and dimensions. After checking, we packed them in bubble bag individually to protect the surface with extreme care.

Finally they were packed into cartons and laid on the pallet wrapped with film to avoid the cartons scattering.

Ningbo Joyo Metal Products Co., Ltd. is a professional custom metal products supplier, not only proficient in product customization, but also excel in various surface treatments.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски