Product Introduction

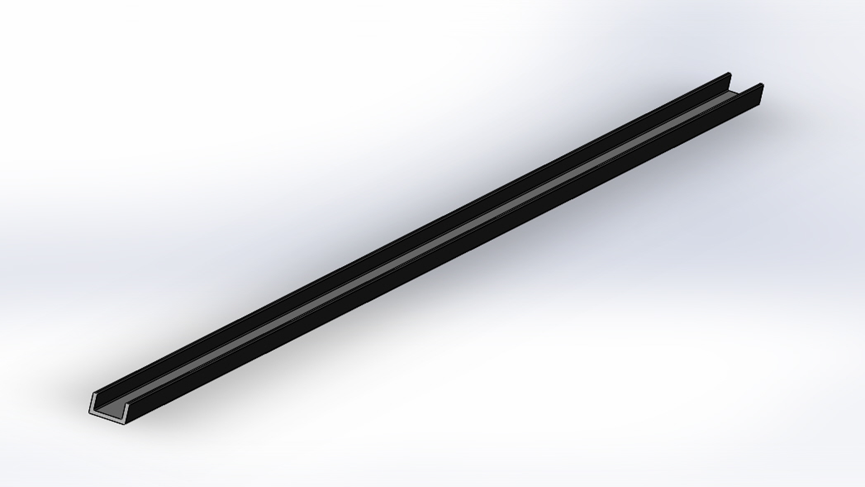

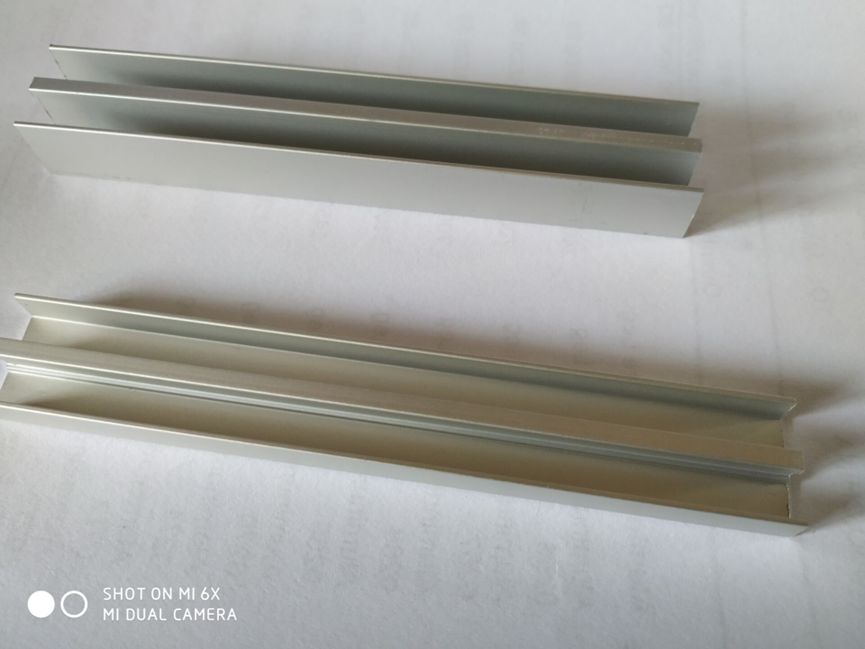

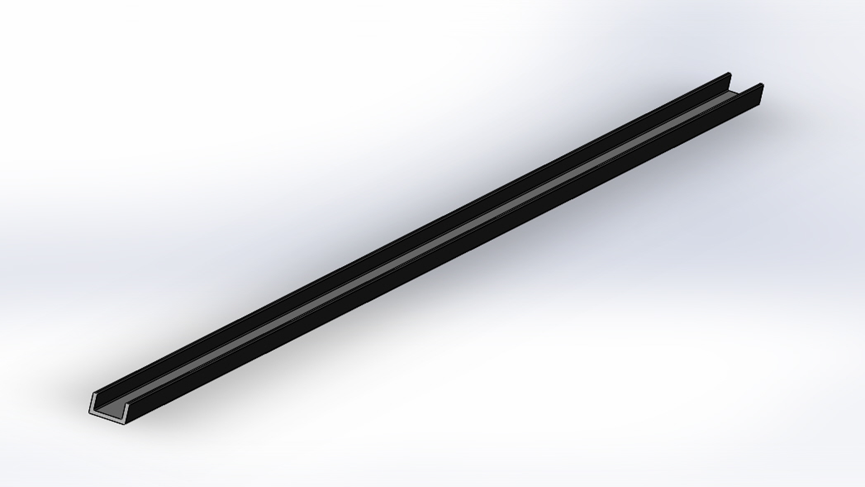

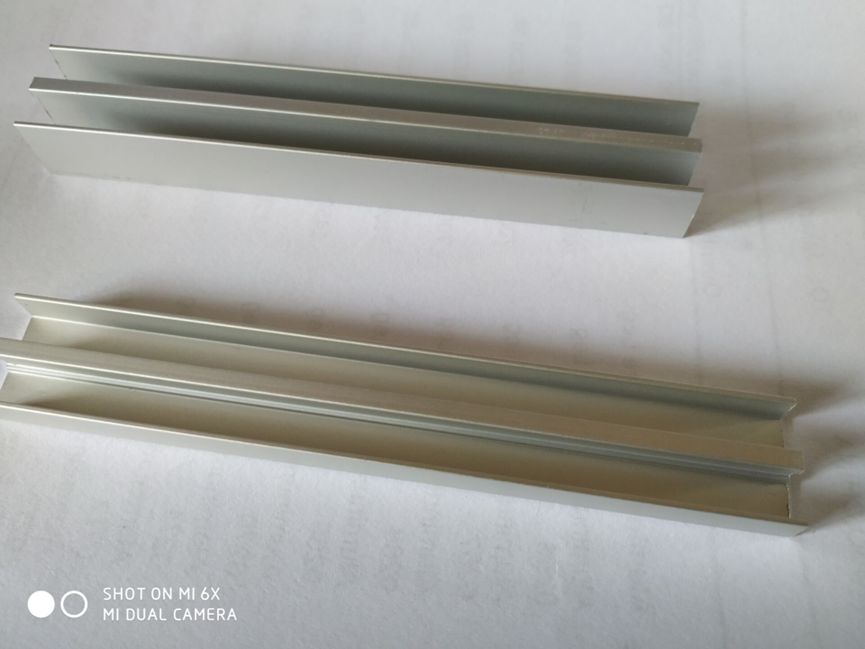

Custom aluminum extruded rails for doors and windows are designed to fit functional needs, by virtue of aluminum's lightweight strength, corrosion resistance. This kind of parts is generally used on furniture tracks. There are different specifications according to different sizes. Below is the picture of the rail assembly:

Material and process

Material advantage

The door or window rails are made from 6063-T6 material. When alloyed with elements like magnesium or silicon, common in 6063 or 6061 alloys, it gains tensile strength. This means rails can support heavy glass panels, wooden doors, or frequent use. Aluminum is lightweight, making installation easier and reducing stress on the window/door frame. Here is the 6063-T6 raw material rod:

Drawings analysis

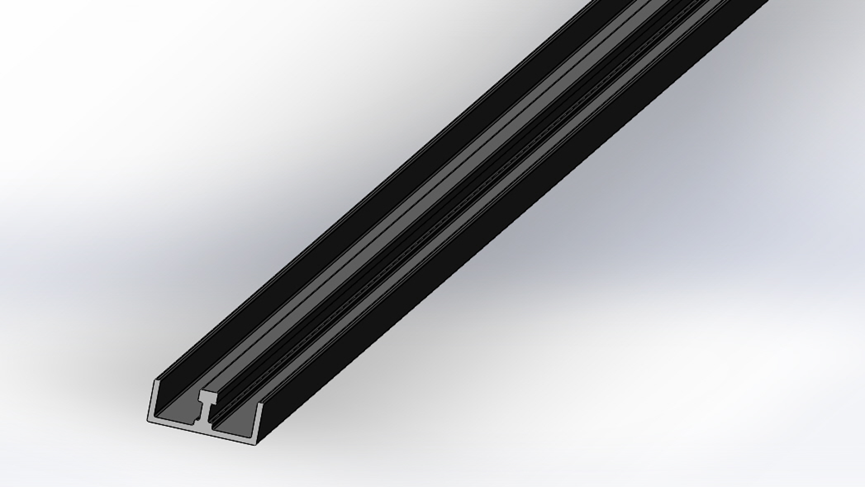

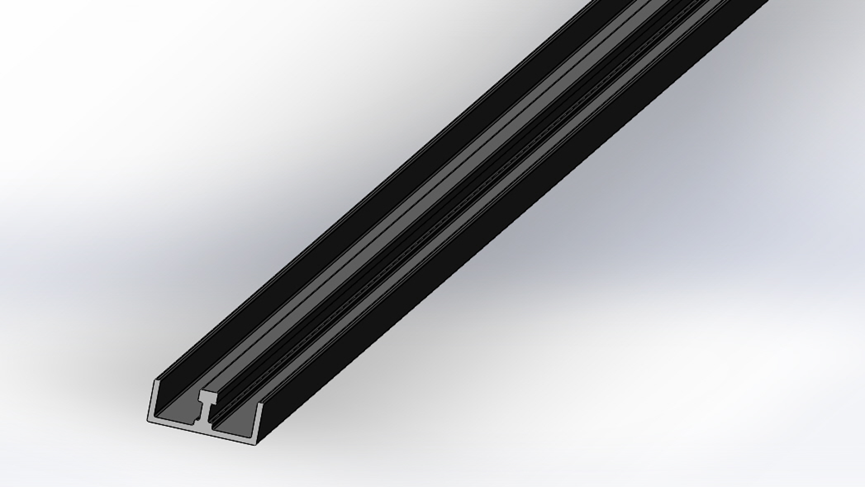

These custom aluminum extruded rails are made by aluminum extrusion. Aluminum extrusion is a manufacturing process, heated aluminum billets are pushed through a steel die to create long, uniform profiles. Here are the rails' 3D drawings:

Manufacturing process

The aluminum extrusion process begins with heating aluminum rod to a certain temperature, typically between 400°C and 500°C, making the metal soft enough to shape. Once heated, the billet is placed in a hydraulic press, where a ram applies high pressure to force it through a custom-designed steel die, a precision tool opening, matches the desired cross sectional shape of the final profile. Below is the extruded machine is working:

As the aluminum flows through the die, it shapes as the die design. This continuous extrusion is then cooled with water to solidify the shape, after it's cut to specific lengths.

Finally, secondary processes like deburring, sandblasting, are applied to the profile, ensuring it meets strict dimensional tolerances and performance requirements for its application. Once the sample is approved, the mass production are began.

Packing

Before the rails being sent, we conduct a full inspection, checking both surface quality and dimensional accuracy. Once all items pass inspection, they are carefully packed into sturdy wooden crates to ensure safe transportation.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски