Product Description

This is a simple, detachable candle holder.

It consists of three parts: a base, a stem, and a top.

The detachable design saves packaging space, which will reduce shipping costs.

Material and Process

This candle holder is made from the CuZn39Pb3 material by CNC machining process. The addition of plumbum makes CuZn39Pb3 a prime example of free-cutting brass. During machining processes like turning, milling, the plumbum particles act as an internal lubricant, reducing adhesion between the tool and the material so lowering cutting resistance. That achieves a smoother surface finish, lower Ra, and reduces subsequent polishing steps.

Below is the 3D drawing of holder parts:

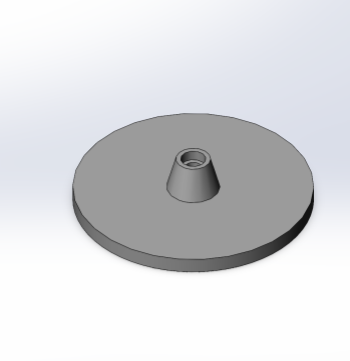

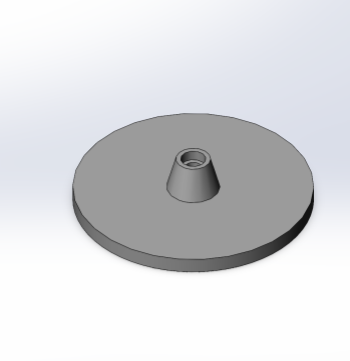

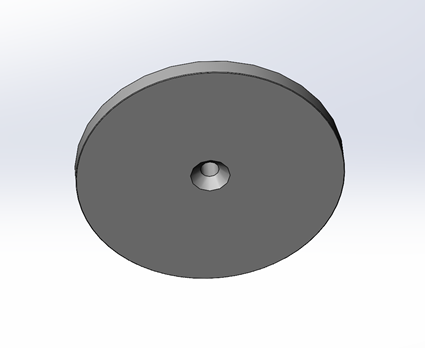

the 3D drawings of candle holder base

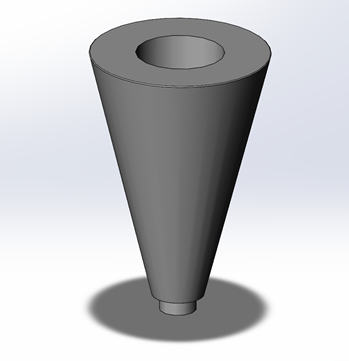

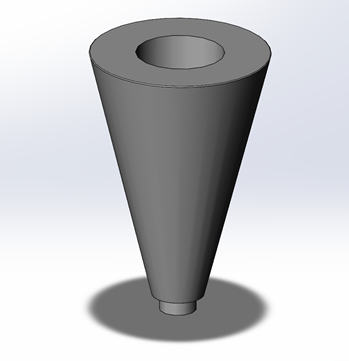

the 3D drawings of candle holder rod

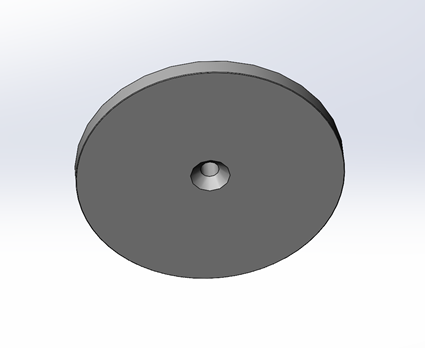

the 3D drawings of candle holder top

The base is made of CuZn39Pb3, directly made from copper bar stock, and processed by CNC into the shape of the drawing.

There is a countersunk head at the bottom for assembling DIN7991 bolts and connecting to the rod. Check out from the below picture:

The rod is made from CuZn39Pb3 as well. The rod is machined directly from bar stock, machine both ends to connect the base and the top, an internal thread is drilled at the bottom and an internal thread is also drilled at the head.

Taking the taper into consideration, the hot heading process is used to make the top, press into the rough shape, and then CNC machining into the specific dimensions. There will assemble an M6 bolt from above to connect the rod.

All parts need to be polished, so clean the workpiece surface of any oil, rust, or impurities is the first step. For rough surfaces, coarse grinding may be used to remove obvious flaws and prepare the surface for fine polishing.

Select tools (e.g., polishing wheels, cloth wheels, sponge wheels) and abrasives based on the material and finish requirements. Rough polishing typically uses larger abrasives (e.g., 80-240 grits), while fine polishing uses ultra-fine abrasives (e.g., 1000 grits and above).

Then electroplated with chrome. Immerse the parts in a dilute acid solution after cleaning for a short time to remove the residual oxide film on the surface, expose the fresh surface of the metal substrate, and enhance the bonding strength between the coating and the substrate.

After the chromium plating is completed, the parts need to be rinsed with clean water to remove the residual chromium plating solution on the surface and prevent corrosion. For parts with high requirements, passivation treatment or drying may also be necessary to ensure the stability of the coating

Packing

The surface is inspected for any flaws, pitting, or peeling is not allowed. For packaging, each piece is wrapped in EPE foam and placed in a box. Then put the boxes on the pallet, tie them with straps, and wrap them with protective film to prevent them from falling apart.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски