Product Introduction

The CNC machining bicycle BB shell is where the bottom bracket is installed, and the crankset is attached to the bottom bracket. It provides a stable mounting point for the crankset, ensuring that it can rotate smoothly. It helps to ensure that all components of the drivetrain are correctly aligned. A properly aligned drivetrain can reduce friction and power loss, improving the efficiency of the bicycle. If the BB shell is not functioning properly, it may lead to misalignment of the crankset, resulting in uneven force application during pedaling and reduced riding performance.

Material and process

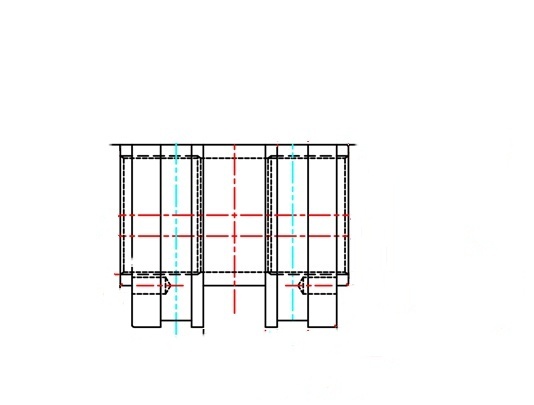

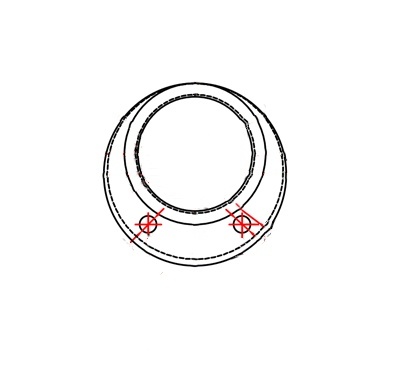

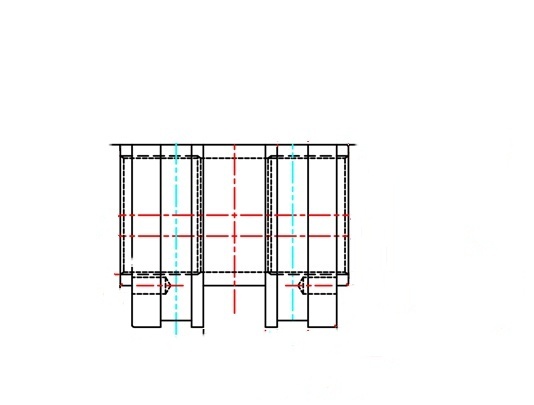

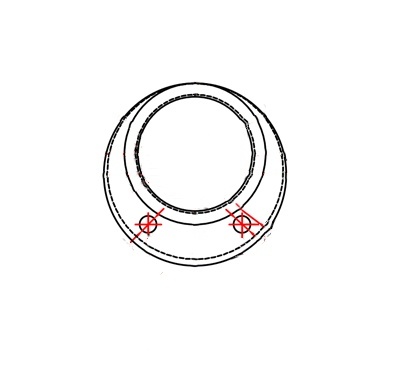

Drawings and analysis:

This customized CNC machining BB shell product is made from aluminum alloy, which is much lighter than steel. And is made by CNC machining process. The BB shell is made according to custom's drawings.

The most distinctive feature is that the center hole of it is eccentric. It is not located exactly in the center. Instead, it has a left thread BC 1.37"x24 TP-L on one side, and on the other side, there is a right thread BC 1.37"x24 TP-R. Such threads are extremely rare. To precisely meet the customer's requirements, we customized two plug gauge. This ensures that the threads are correct. A plug gauge, also known as a hole gauge or internal diameter (ID) gauge, is a precision measuring tool designed to verify the accuracy of internal dimensions, such as holes, bores, or cylindrical openings.

Processing

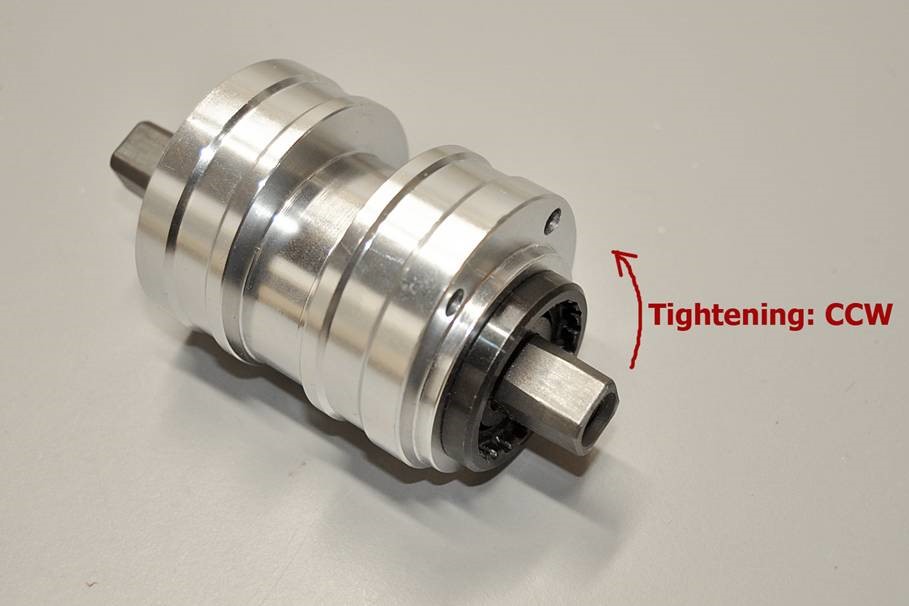

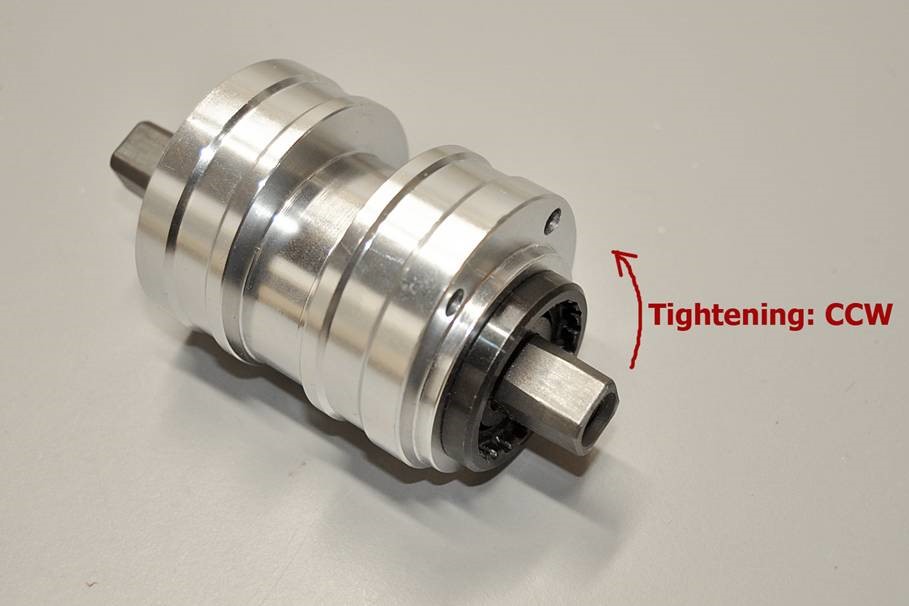

To ensure qualified assembly, we have also procured matching shafts. These shafts are specifically designed to complement the components in the assembly, with critical dimensions and tolerances carefully coordinated to achieve optimal fit and functionality.

For this product, the material used is 6061-T6 round bars with an outer diameter of 60. They are directly machined and finished on the CNC machine. A specially designed eccentric fixture was used. The holes produced by this process are eccentric and in accordance with the drawings. The threads were also machined in one go on the CNC machine.

Surface finish

After machining, the surface is treated with natural or black anodizing.

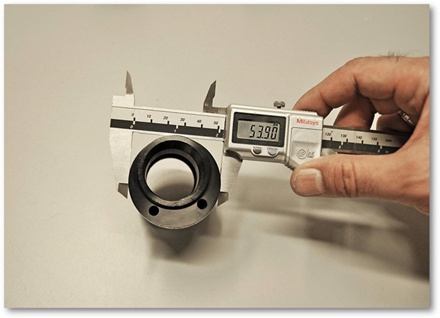

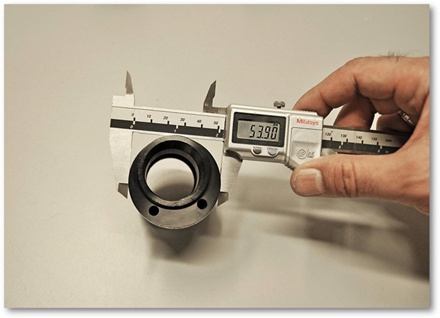

Inspection

And the final products undergo strict inspection to ensure dimensions are within tolerance and surfaces are defect-free. This involves verifying dimensions with tools like calipers, inspecting surfaces for flaws, and testing anodizing quality for thickness, adhesion, and corrosion resistance.

Packing

The products should be individually wrapped in bubble wrap, each item is enclosed in bubble film to prevent scratches, impacts, or vibration damage during transit, then placed in cartons and cartons are stacked on wooden pallets, secured with stretch film and corner protectors to maintain stability.

Ningbo Joyo Metal Products Co., Ltd. offers one-stop services from production to delivery, integrating every stage of the supply chain to ensure efficiency and reliability. This end-to-end approach eliminates supply chain gaps, reduces lead times, and provides clients with a single point of contact for seamless project management from concept to doorstep.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски