Product Introduction

This is an aluminum gearmotor part. Crafted to withstand external impacts and secure gears, shafts, and the motor, it often features materials like cast iron, aluminum alloy which is lightweight with superior heat dissipation, stainless steel , or engineering plastics. Key features include cooling fins to dissipate heat generated by the motor and gears, sealed interfaces, and mounting flanges for secure installation. Modern trends focus on lightweight alloys, integrated sensors for real-time condition monitoring, and eco-friendly materials, ensuring the housing remains a critical factor in gearmotor reliability and longevity.

Material and process

This gearmotor is made from aluminum material, and undergone investment casting process first, then CNC machining the surface.

Aluminum alloy has a low density, this makes gearmotors lighter, ideal for applications where weight reduction is critical. Lighter housings reduce the inertia of rotating components, allowing the gearmotor to accelerate faster and consume less energy during operation.

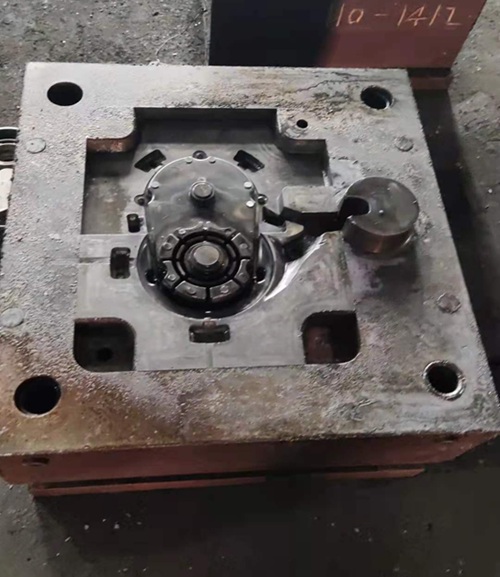

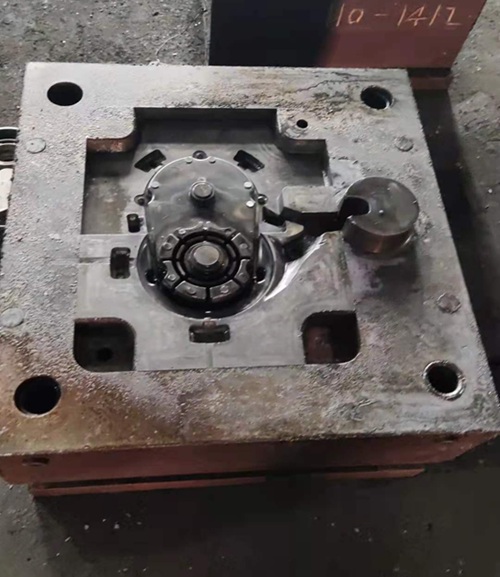

After the material confirming, then the first step is making mold of the gearmotor.

the gearmotor mold-1

the gearmotor mold-2

the gearmotor mold-3

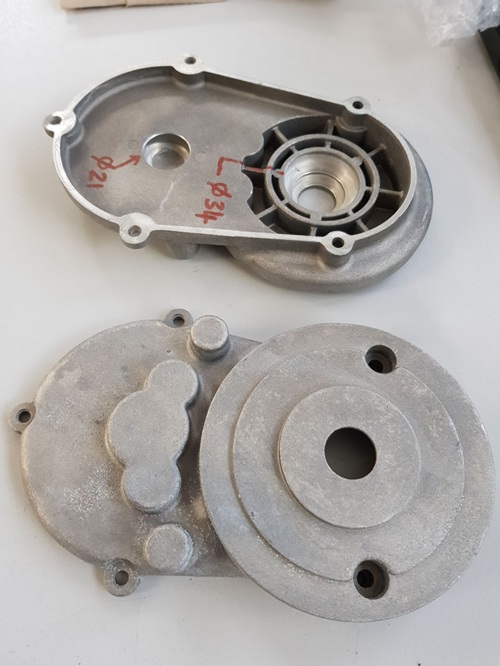

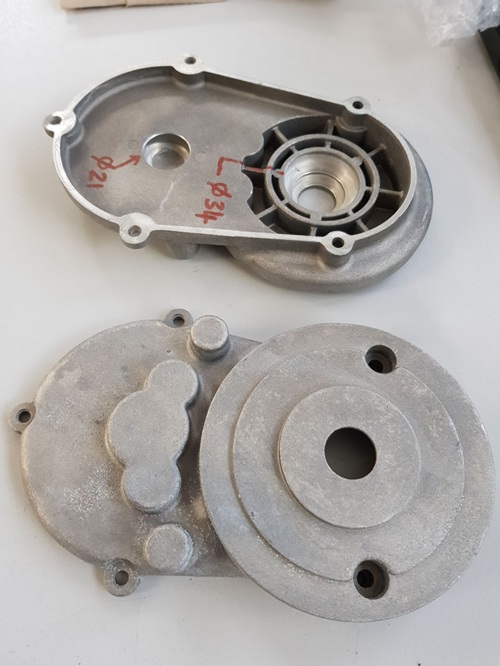

Then the mold is installed, the prototype is tested, and the cast product is produced.

After the samples getting approval, we begin to produce the mass production.

Gearmotor shell mass production

The flange mass production

The rough parts need to be deburred, ground and sand blasted to get the nice surface. And CNC machine the inner suface.

Packing

We have inspected the surface and dimensions to ensure product qualification, visually examining for defects like scratches, burrs. This thorough inspection ensures that each product meets both aesthetic and functional requirements, minimizing the risk of non-conformity before shipment.

Measuring the height:

The gearmotor was packed individually in boxes to protect the surface. Outer is wooden cases to gather the box for cushion the bump during the shipment.

Ningbo Joyo Metal Products Co., Ltd excels in integrating diverse manufacturing processes to offer one-stop services, streamlining supply chains and enhancing efficiency for clients. Our comprehensive capabilities span the entire production cycle, from design to delivery, with a focus on process integration and technical expertise.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Беларуская мова