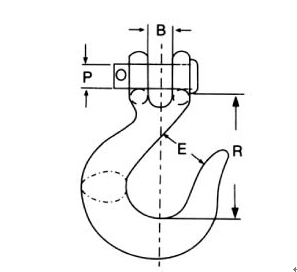

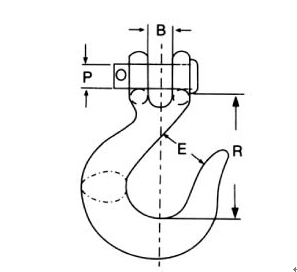

Product Introduction

This is a custom-made winch hook, which is designed by our customer. The hook's base material is alloy steel undergoes a rigorous manufacturing process: first forged or machined to shape, then treated with a zinc plating layer, followed by a chromate conversion coating that produces the characteristic iridescent "rainbow" finish.

Material and Process

Material introduction

Alloy steel is used to make the hook, and the hook is made by hot forged process.

Manufacturing Process

First, we begin to work the hook with the drawings and the dimensions which is provided by the customer:

Hot forging is carried out at high temperatures typically 1,050–1,200°C, where the steel billet is heated to a plastic state, then shaped by dies under hydraulic or mechanical presses. The hot forged process minimizes material waste compared to machining, as the forging process flows metal into the desired form.

After hot forging, the rough parts is come out.

The resulting blank undergoes post-forging steps cleaning scale, typically via shot blasting with steel grit or acid pickling in hydrochloric acid to remove mill scale, rust, and oxides, ensuring a clean substrate for plating. After descaling, the hooks enter the color zinc plating line. Zinc ions deposit from an electrolyte bath to form an 8–15μm thick layer.

Packing

Before packing we conduct the inspection of the hook surface and dimensions to ensure they are qualified.

Then pack then with bubble bag individually and put into cartons. And laid the cartons on the pallet, wrapped with protective film to avoid the cartons scattering.

With decades of industry expertise, Ningbo Joyo Metal Product Co., Ltd. approach to manufacturing is rooted in meticulous precision, where every production process is executed with uncompromising attention to detail. Our seasoned team oversees each stage from material selection to final inspection.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски