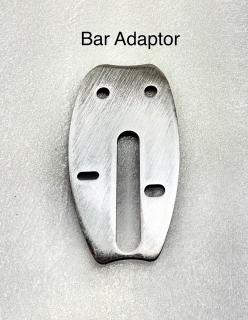

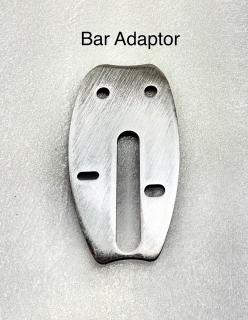

Product Introduction

This is a alloy steel bar adapter made by laser cutting first, then CNC machining. And this is a kind of guide plate using on the chainsaw.The guide plate, also known as the chain plate or saw plate, is a core component of the chainsaw transmission system. Its main function is to support and guide the saw chain to complete the cutting operation. The material is mostly 50 Mn steel or 65 Mn steel. According to the structure, it is divided into two types: combined type and integral type. The combined type is formed by welding or riveting multiple steel plates, and can be divided into laminated type and replaceable head type.

Material and Process

Material introduction

Our adapter used the material alloy steel 50CrV4. 50CrV4 is a high-performance alloy steel renowned for its exceptional combination of strength, toughness, and fatigue resistance. Vanadium carbides precipitate during heat treatment, reinforcing the matrix against abrasive wear. Chromium improves resistance to surface fatigue in cyclic loading.

It's moderate machinability and can be cold-formed into complex shapes before heat treatment, though high-strength applications often require hot working.

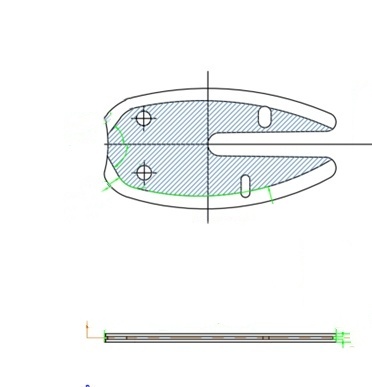

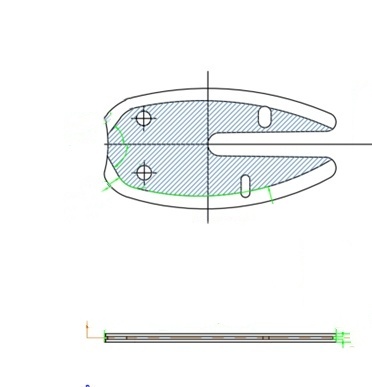

Drawing analysis

Here is the sketch of the adapter:

Manufactring process

The process begins with laser cutting a hot-rolled alloy steel plate, followed by grinding the cut surfaces for smoothness. Next, a CNC milling operation creates a groove with a width of 1.575 inches (±0.005 inches tolerance), ensuring it is centered precisely on the plate. This sequence ensures dimensional accuracy and surface quality critical for high-precision applications.

Then grind the top and bottom faces to a smooth, flat finish.

Afterwards, the bar adapter undergoes heat treatment to achieve a hardness of HRC 40-42.

Finally, each adapter is sprayed with hydraulic oil as a rust-prevention measure.

Packing

To protect the surface, each bar adapter is individually packed in a plastic bag, then placed in a carton. The cartons are stacked on a pallet and wrapped with stretch film to prevent shifting during transport.

Ningbo Joyo Metal Product Co., Ltd is careful in every aspect from material selection to packaging, maintaining strict quality control throughout the process. We source premium materials and verify their certifications, implement in-process inspections during manufacturing to ensure precision within tight tolerances, conduct rigorous functional and durability tests on components, and secure palletization to prevent damage. This comprehensive approach guarantees that each product meets our high-quality standards before delivery.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски