Product Introduction

This is a connector used in building industry and they are made by investment casting process. Custom investment casting steel connectors bridge design complexity with mechanical reliability, enabling the production of high-precision components for critical applications. Their ability to handle intricate geometries, combined with material versatility and tight tolerances, makes them indispensable in industries.

Material and process

Material introduction

This is a small bracket used in construction, made of 1018 steel, a type of mild steel. With a carbon content of approximately 0.15%–0.20%, 1018 steel endows the bracket with excellent formability and weldability, making it suitable for processes like stamping, bending, and welding to achieve precise structural designs. As a low-carbon steel, it offers balanced mechanical properties: while its tensile strength is typically 450–550 MPa, its high ductility ensures the bracket can withstand certain deformation without cracking, ideal for building components requiring flexibility.

Drawings analysis

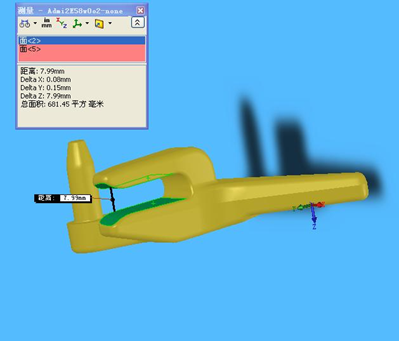

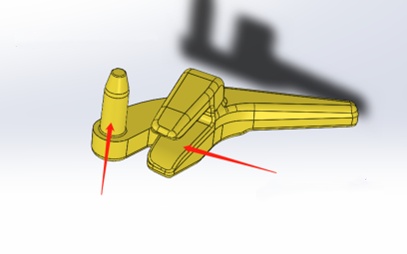

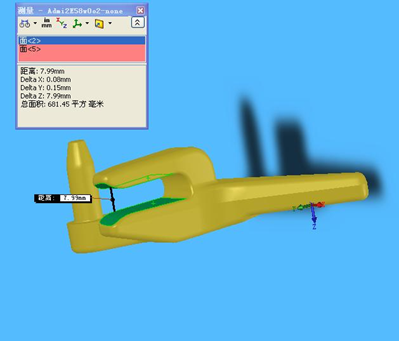

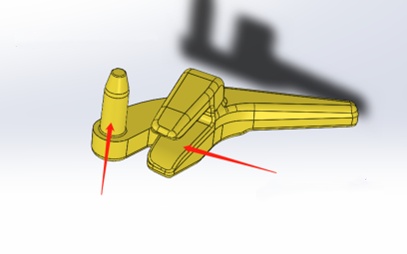

Here are the connector 3D drawings, the outer diameter of the pin and the size of this opening indicated by the arrow are of great significance. Otherwise, the assembly will be affected.:

Then we confirm to use the water glass slurry to cast the connector.

First step should be making the wax pattern and welding them to form the wax tree.

The wax pattern is dipped in a water glass slurry, then coated with refractory sand, and repeat this step 5-8 times to form a hard shell. The wax is melted out, leaving a hollow shell, sending for high-temperature baking and hardening.

Molten steel is poured into the baked shell, filling the void left by the wax pattern. When the steel is solidification and shell getting cold, the shell is broken away by vibrating, and the casting is cleaned and cut off from the tree. Here are the photos of rough castings:

Surface treatment

The product should undergo hot-dip galvanizing. There are two types of hot-dip galvanizing: one has a brighter surface, and the other is dull. The customer chose the dull one.

Packing

Before shipment, conduct destructive tests on the product. Hit it with a hammer and it just deform but not break.

That is qualified and successful

For this product, our customer request to pack them in bucket and put on the pallet. So we put the connector into bucket in bulk and palletized, using the strip to fix the buckets avoiding them scattering.

packed in bucket 1

packed in bucket 2

stack the buckets on the pallet

load into cabinet

loading is complete

Ningbo Joyo Metal Products Co., Ltd. accepts custom orders for as few as 10 pcs, while also capable of handling large-scale production runs of up to 100,000 pieces. This flexible capacity allows us to serve both prototype development for small batches and mass manufacturing for bulk orders.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски