Product Introduction

This dowel pin are made from mild steel, 1045 steel. Different models vary significantly in diameter, length, and dimensional tolerances (ISO h7, g6, etc.). A dowel pin is a cylindrical mechanical component, typically made of steel, stainless steel, or brass, used primarily for positioning and aligning parts in assemblies. It restricts linear movement (X, Y, Z axes) and rotational alignment between mating components, ensuring assembly accuracy.

Material and process

This pin is made from 1045 mild steel rod and CNC machining process is used to work the pin. Mild steel, also known as low-carbon steel with carbon content typically below 0.25%, can be machined, drilled, or cut with standard tools without excessive wear on equipment. Low carbon content prevents tool blunting, allowing efficient production of parts like bolts, nuts, and brackets. So its material is suitable for CNC machining.

Here is the pin drawings sent from our customer,

We conduct a comprehensive analysis, it needs to be machined first and then chamfered and drilled the holes.

At its head position, a larger amount of material has been removed. Therefore, we will first turning the material at the head position.

Next CNC turning the pins precisely:

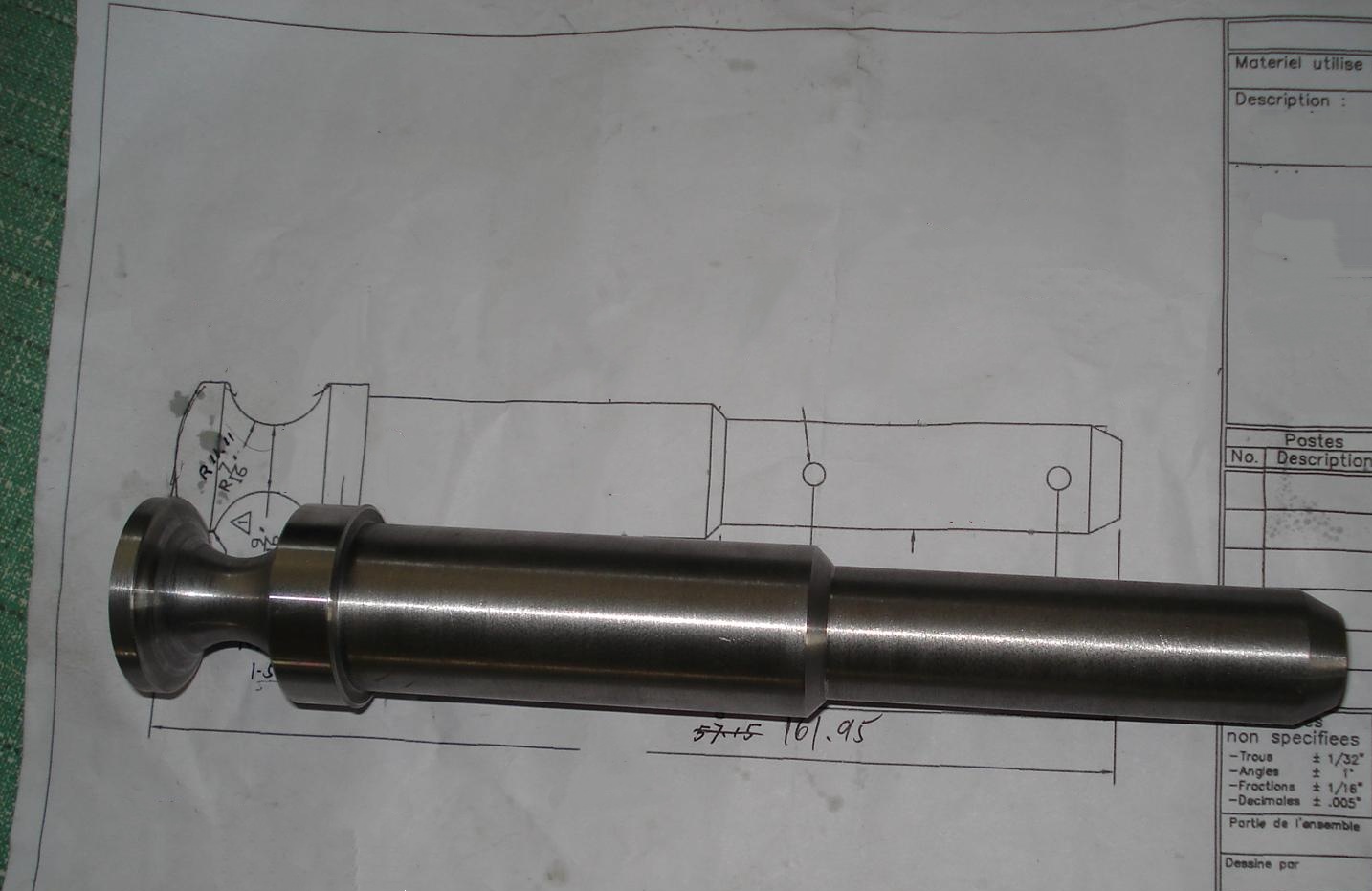

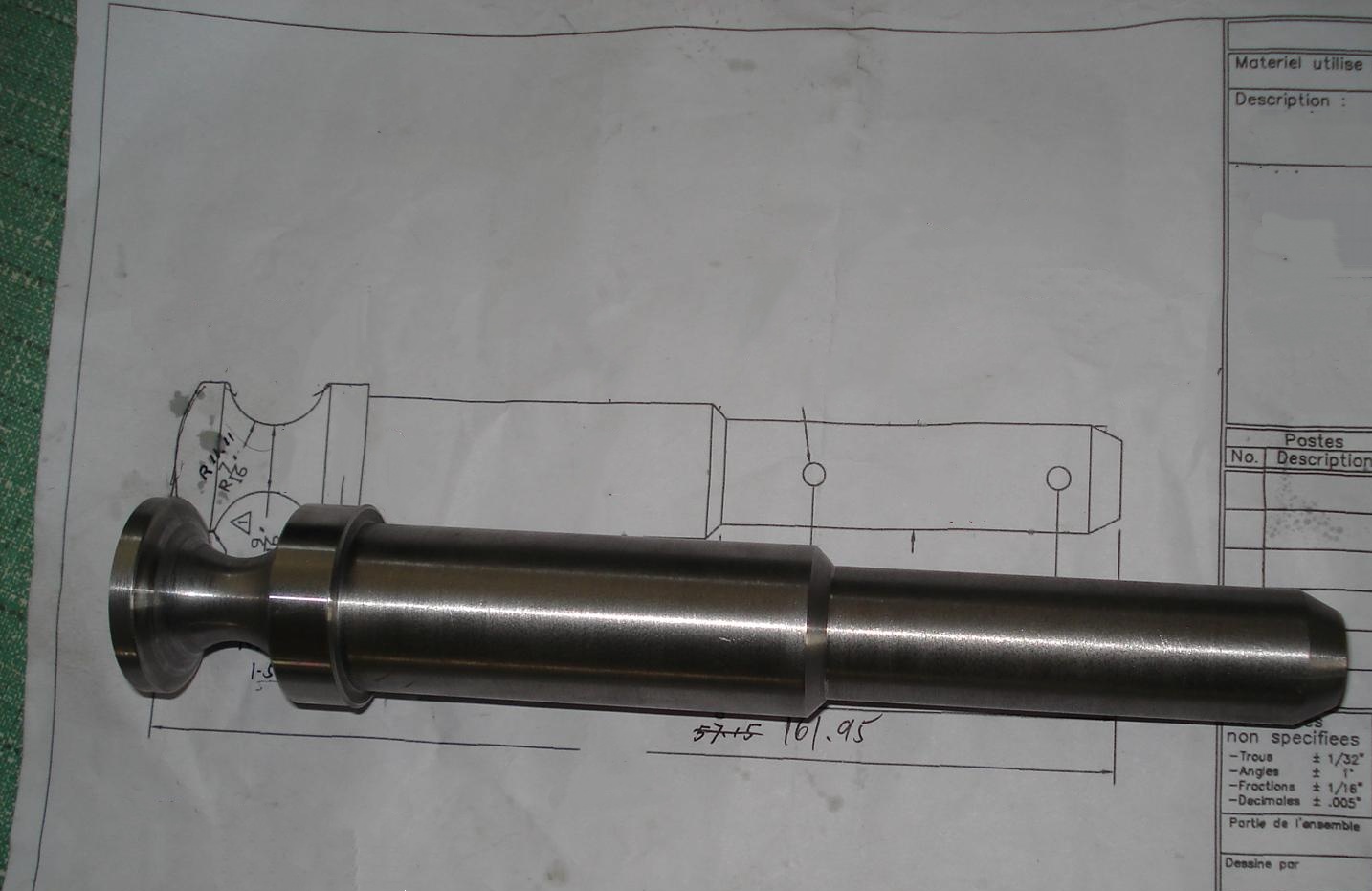

Then the pins are worked out.

the pins before galvanization-1

the pins before galvanization-2

the pins before galvanization-3

They still need to undergo galvanization. This process is essential for enhancing their corrosion resistance and durability, especially for applications in humid or corrosive environments. After galvanization, the pins should be inspected for uniform coating coverage and freedom from defects like bare spots or excessive zinc buildup, ensuring they meet quality standards for assemblyThe belows are finished pins:

Packing

Before shippment, we inspect the dimensions carefully with caliper to ensure they are qualified.

For this batch of goods, they are packed in bulk into cartons first and then put into wooden case. This approach ensures that the products are placed in the cartons without fixed arrangements, and then the cartons are put into wooden case to avoid the bump during the transportation.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски