Product Introduction

Stainless steel barb fittings find extensive application in the fluid industry, with our custom-manufactured variants primarily utilized in ice cream machines. Crafted from food-grade stainless steel. Whether for conveying liquid ingredients, coolant lines, or sanitary tubing, our custom barb fittings integrate industry-standard fluid handling functionality with the specialized hygiene requirements of ice cream manufacturing equipment.

Material and process

Drawings analysis

As used in food industry, material is pretty important, it must reach to food grade stainless steel.

There are many types of fitting, like elbow-1” spout.

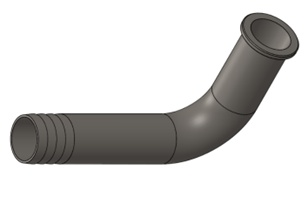

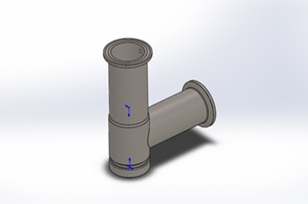

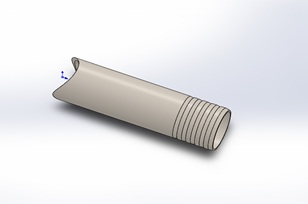

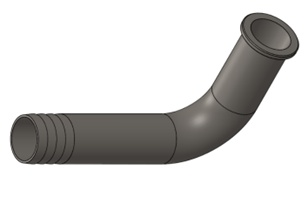

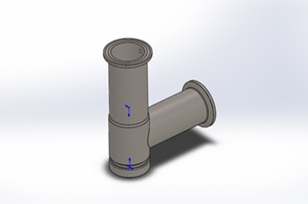

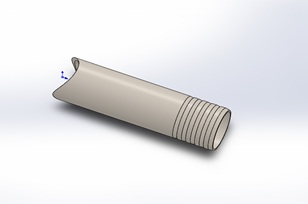

The following pictures are the barb fittings 3D drawings which are sent from out customer.

3D drawings-1

3D drawings-2

3D drawings-3

Manufacturing Process

The first one is consist of two components, which are welded to form an integrated structure: one end features a bent connector, while the other end is a nozzle. They all need to be CNC machined first. Then post-welding, both internal and external surfaces undergo precision polishing, with particular emphasis on the inner bore. This finishing ensures the internal flow path is smooth and free of burrs, minimizing fluid resistance and optimizing flow efficiency. The polished inner surface also reduces material deposition and facilitates easy cleaning, making it suitable for applications requiring high-flow performance or sanitary conditions. Below is the inner sideview of the barb fitting:

Below is the comparison of the surface before and after polishing.

The manufacturing processes for other shapes follow a similar workflow, primarily comprising CNC machining, bending, welding, polishing, and other operations. Some vertical nozzle with ferrule need to be welded the ferrule.

There are some of finished barb fittings mass production:

finished barb fittings -1

finished barb fittings -2

finished barb fittings -3

Packing

We use food-grade plastic bags for packaging. This packaging solution balances food safety requirements with practical protection, ensuring our parts remain sanitary and ready for integration into food-grade systems.

Ningbo Joyo Metal Products Co., Ltd has extensive experience of ice cream machine. Our products cater to a wide range of industries, demonstrating versatility and adaptability across diverse sectors, our solutions are engineered to meet the unique requirements of each field.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски