Product Introduction

It's a kind of exhaust manifold used in automotive industry, which is made from stainless steel material by casting process. The stainless steel construction and casting processes ensure it thrives in the most demanding operating environments, aligning with the strict quality standards of OEM automotive production.

Material and process

Stainless steel is the material of choice for OEM exhaust manifolds. It resists rust and degradation from moisture, exhaust byproducts, and environmental elements, extending service life. The stainless steel can maintain mechanical integrity under thermal stress and vibration, reducing the risk of cracks or leaks.

The sample sent from our customer is the assembly bracket of the manifold.

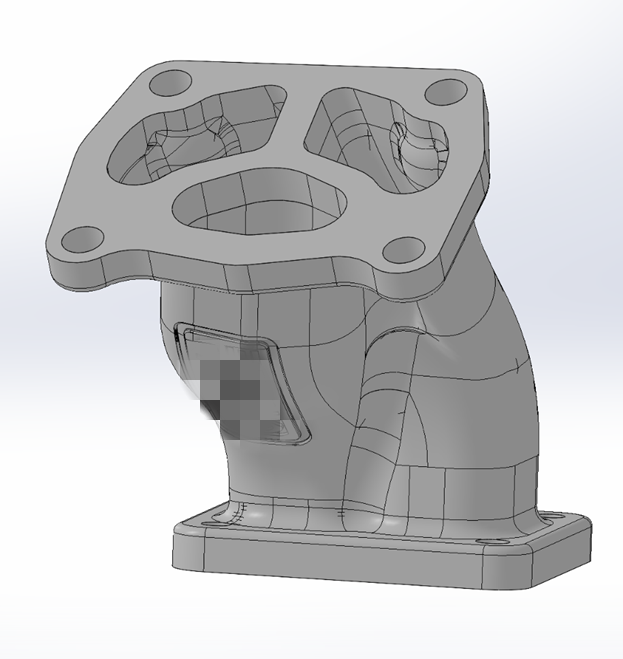

Here is their assembly picture:

The picture from our customer shows the exhaust manifold which is connected by welding process, but the whole exhaust manifold made by casting process is what we need to work.

There is 2 ports on one flange and the other flange has 3 ports, so that it can connected to the bracket. After analyzing and measuring, the 3D drawings is designed accroding to the requirement of our customer. It's really challenging to work.

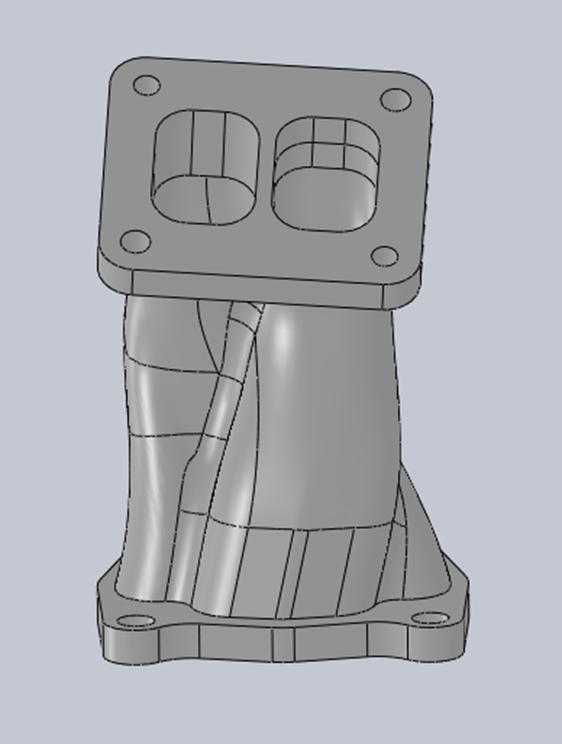

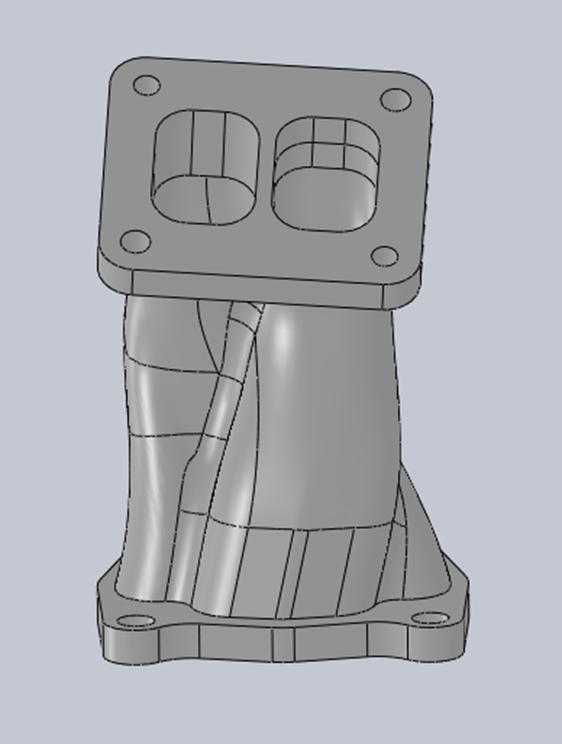

Here are the 3D drawings:

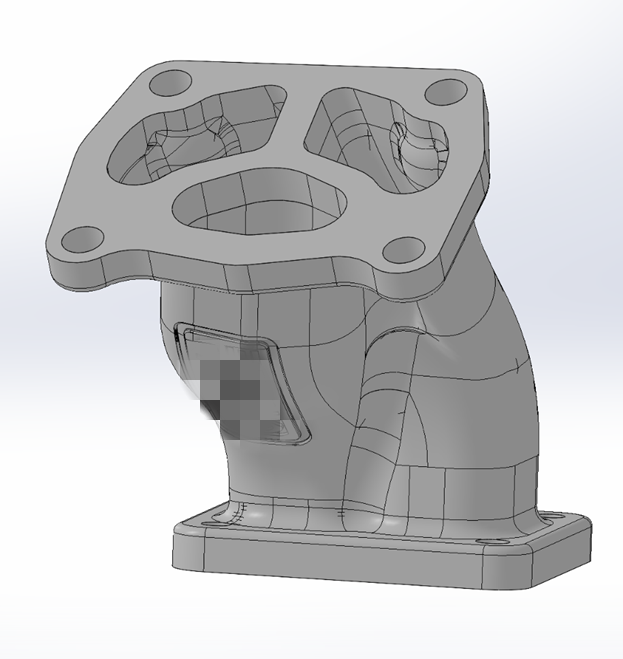

Then we move up to 3D print the manifold when the 3D drawings get approved.

Using 3D printing technology to create prototypes is a very good choice, as it can avoid the problems that arise from directly making mold and samples.

There are some details need to adjust when the 3D printed prototype comes out, then revised the drawings and continued with 3D printing. We repeat this several times in a row and finally succeeded.

Here is the finially version:

This process has gone through stages such as design prototyping, drawing creation, revisions, and final confirmation, ensuring that every detail aligns with functional requirements and manufacturing feasibility.

After multiple iterations, the finalized drawings and prototypes undergo rigorous approval. This includes verifying compliance with industry standards and customer requirements, ensuring the design is both manufacturable and fit for its intended application. Only then does the process move to mold fabrication and full-scale production.

Ningbo Joyo Metal Products Co., Ltd. strength lies in the seamless execution of the entire pre-production cycle, from design prototyping to final confirmation, ensuring that every stainless steel investment casting part meets the highest standards of precision and manufacturability.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Беларуская мова