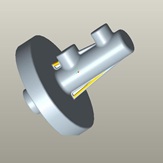

Product instruction

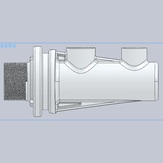

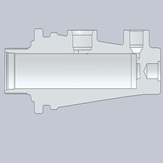

The high quality aluminum cylinder is used in automotive brake system, which is needed cylinder slide 100,000 times.

It needs pretty high requirement of size tolerance and inner finish roughness.

Material and Process

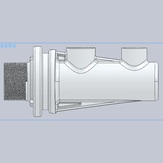

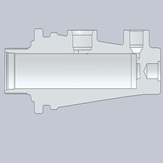

1. Our engineer analyzed the 3D drawing sent from our customer, which is used in CNC machining, and then creat the correct casting drawing, as the following pictures showing:

master cylinder body drawing analisis -1

master cylinder body drawing analisis -2

master cylinder body drawing analisis -3

master cylinder body drawing analisis -4

drawing for casting of cylinder body confirm

2. The suitable material is aluminum alloy A356, with heat treatment T6, which is easy to casted for permanent tooling.

3. The aluminum casting part comes out by a steel alloy mold, used in gravity casting process. Regarding the high quality requirement, any holes or porosities are not allowed inside. Then the casting are cut into pieces to check.

aluminum casting cylidner body after tooling

aluminum gravity casted cylinder body

aluminum casting part cut to check sand holes

no sand holes found in aluminu m castings

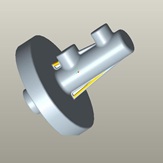

4. The castings are fixed on CNC turning machine, machining the thread and outer surface exactly as drawing.

CNC multiple turning

CNC working in one step

CNC turning the product

CNC turned thread in one end

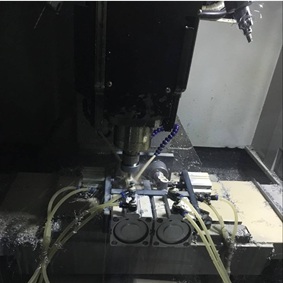

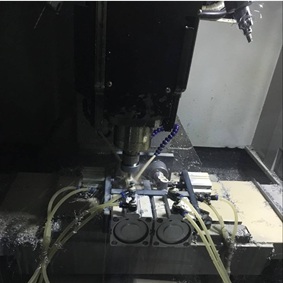

5. After that, deep center holes to be worked in special deep hole tooling machines and vertical holes location needs to be worked in 4 -axis milling machine, special the small holes. The specialized equipment allows for precise drilling of holes with a depth-to-diameter ratio ≥5:1, minimizing deflection and maintaining straightness.

CNC deep drill machine inside

deep hole drill machine

deep hole drill tooling showing

CNC milling the small holes in 3 axis CNC machine

CNC milling and taping holes

small hole taping tool

Inner hole surface roughness is another key important issue, honing the hole with special tool is necessary.

Then all the machining processes are finished.

QC inspection

The key lies in the smooth surface and strict length tolerance. As traditional calipers are failed to meet the measure requirement, we adopt a specialized inspection method. The workpiece is cut into two halves by using a saw, place each half on an Image Measuring Instrument (IMI) , cross-check measurements from both halves to eliminate sectioning errors. This method solves the measurement challenge for precision parts, ensuring both dimensional accuracy and surface finish.

cutting into two pieces to check inner surface after honing

12pcs cut to size inspection

inner holes surface Section 1

one section after cuting

The pictures depict a workpiece being inspected for dimensional size and tolerance on an Image Measuring Instrument.

inspection size and tolerance in image measuring instructment

inspection size in image measuring instructment

size inspected by image measuring instrument

Mass-production

Once all dimensions, tolerances, and surface finishes are confirmed by the client, mass production will be produced.

Raw material like certified stainless steel ingots are purchased, and tooling is calibrated. Core processes, such as silica sol casting, involve injecting wax patterns, building shells through multiple slurry-dipping layers, melting metal, and pouring into preheated molds. Then they are sent to machining the thread and outer surface and drill the center hole.

mass-production after size approved

mass production with qualified process

Packing

Reverify critical dimensions, ensuring no bump or surface defects. Clean parts with alcohol wipes to remove oil, dust, or metal debris. Each one is wrapped with bubble bag to protect and put into wooden box with shipping mark.

Moreover, there are some different size master cylinder bodies worked by our workshop for different applications.

Ningbo Joyo Metal Parts Co,.Ltd. is specialized in manufacturing high-precision products, demonstrating expertise in silica sol casting for complex geometries, tight CT6 tolerance control. Our capabilities are backed by comprehensive quality assurance, ensuring precision across casting, machining, and surface treatment for demanding applications in high-precision industry.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски