Product Introduction

It is a kind of fork pipe made from aluminum material by welding, used in wheelchair industry. Custom aluminum welding fork pipe is a highly adaptable solution, bridging material science, precision engineering, and advanced welding techniques to meet the exact needs of wheelchair industries.

Material and process:

It is made from alumium rod and aluminum block material. Aluminum's density 2.7g/cm³ is roughly 1/3 of steel, making it ideal for weight, aluminum alloys offer excellent weldability, allowing seamless fusion. TIG welding is preferred for precision and clean aesthetics, used to weld thin where minimal heat distortion and smooth weld seams are critical.

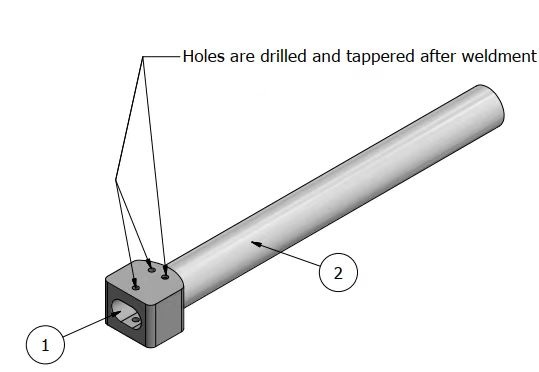

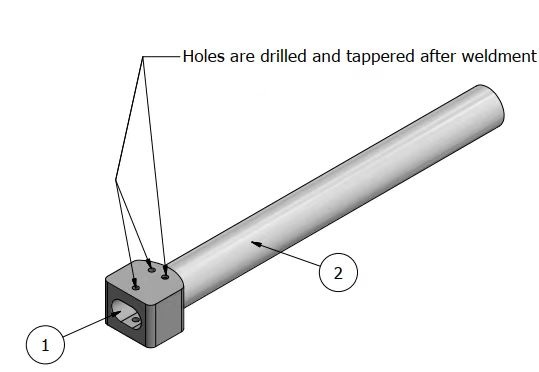

Here is the drawings of the fork pipe:

It is consist of two parts: one is the head, which needs to be precisely carved by CNC machining center.

Another one is an aluminium tube. The two part were welded together by argon arc welding.

It is composed of two different parts, each playing a crucial role in the overall structure. One part is the head, a component that demands an extremely high level of precision. To achieve this, it needs to be carved by a CNC machining center. The CNC machining center, with its advanced computer, controlled system and high-precision cutting tools, can execute complex machining operations with an accuracy. This ensures that the head has the exact dimensions, shapes.

The other part is an aluminium tube. Aluminium, chosen for its favorable properties such as low density, good corrosion resistance, forms the tubular structure. This aluminium tube serves as a base.

They are joined together through argon arc welding. Argon arc welding is a welding process that uses argon gas as a shielding medium to protect the weld area from atmospheric contamination. This welding method is particularly suitable for aluminium and its alloys because it can produce high - quality, strong, and durable welds with minimal distortion.

Surface finishes required according to our customer's demand, the fork pipe has undergone the sand blasted and blacke anodized.

Packing

For these parts, we implement a strict individual packaging method to ensure comprehensive protection throughout every stage of handling, storage, and transportation. Each fork pipe is carefully placed into its own dedicated packaging.

This individual wrapping serves multiple protective purposes: it creates a physical barrier that prevents direct contact between parts, eliminating the risk of scratches, dents, caused by friction during movement.

For delicate surfaces, the packaging material is chosen to be non-abrasive and chemically inert, avoiding any potential damage to these critical features.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски