Product Introduction

These are front and back bracket used in wheelchair, which are worked by extrude aluminum profile with two molds.

The back tube of two side facet are worked by CNC milling process, welding the plate in one side.

The front tube are bended by mold, then CNC milled by 3-axis machine. Welding the round boss in one end.

Material and process

These backets are made from aluminum profile by extruded profile.

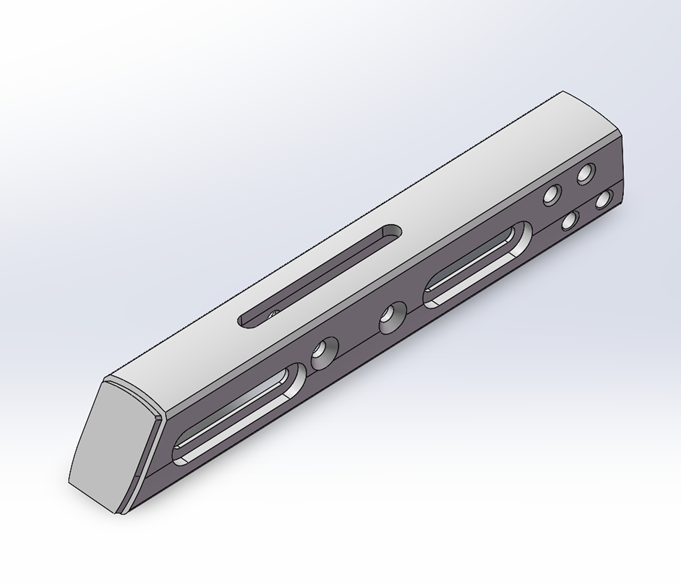

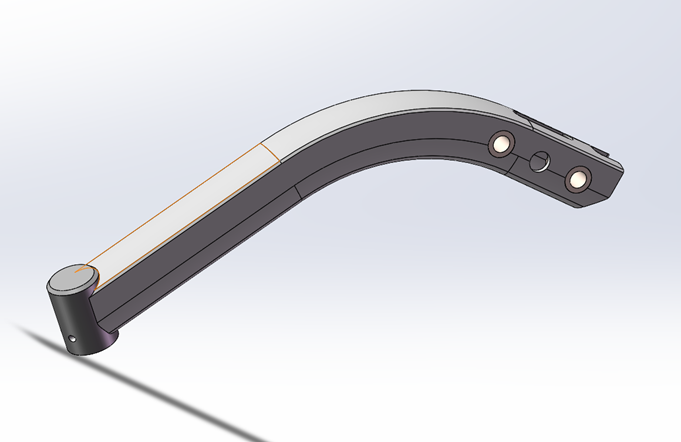

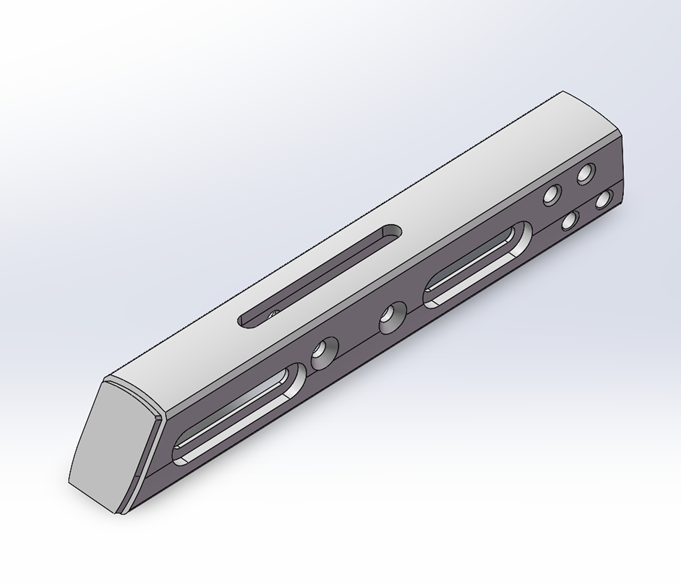

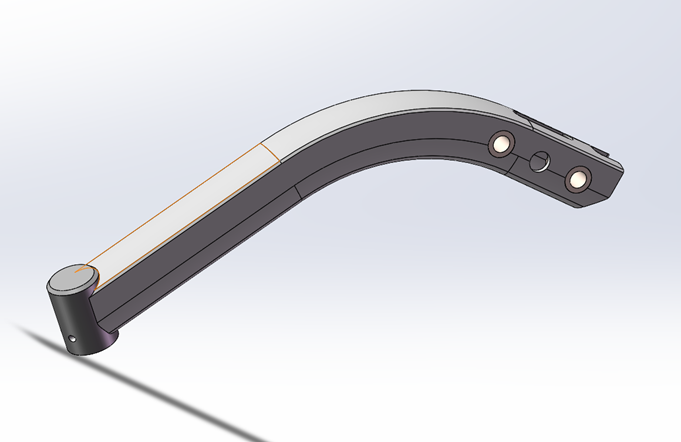

Below are the 3D drawings of the front and back bracket from our customer.

Then our team analized the drawings, these need to make 2 molds and made of aluminum alloy 6063-T5 material.

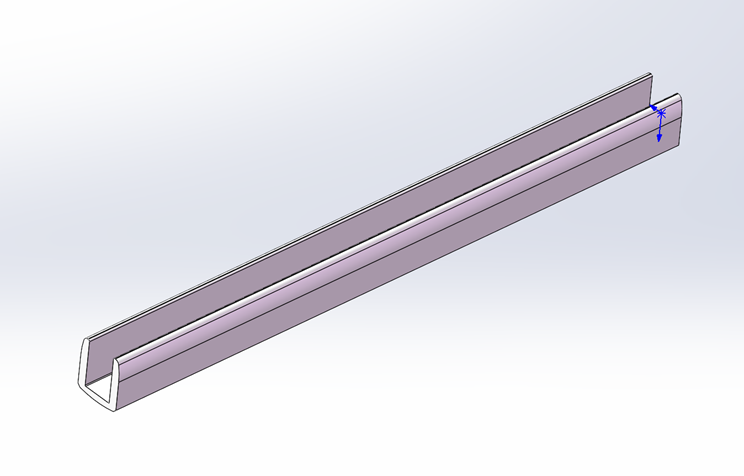

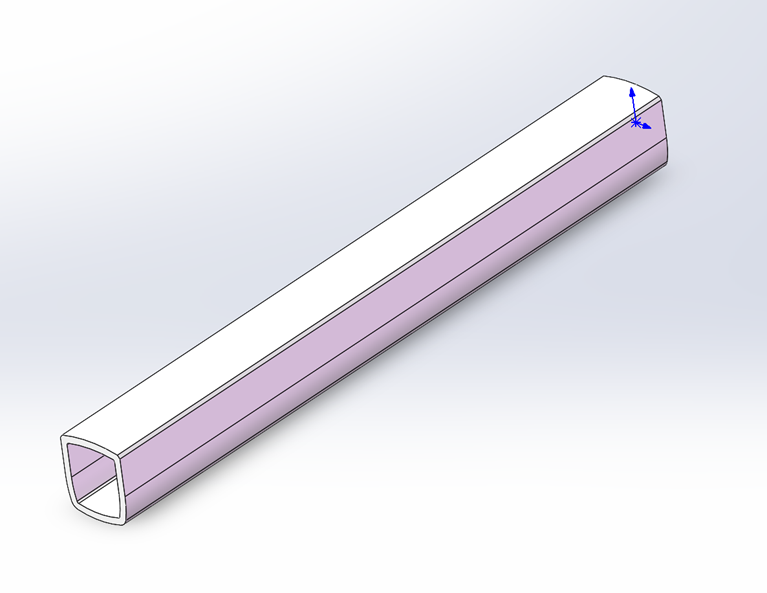

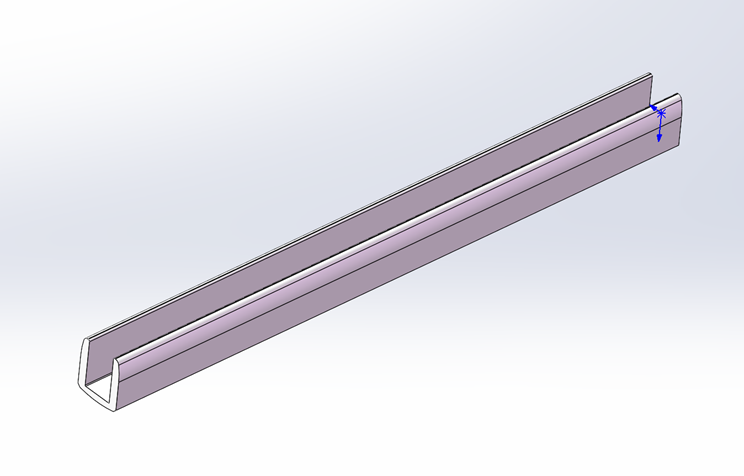

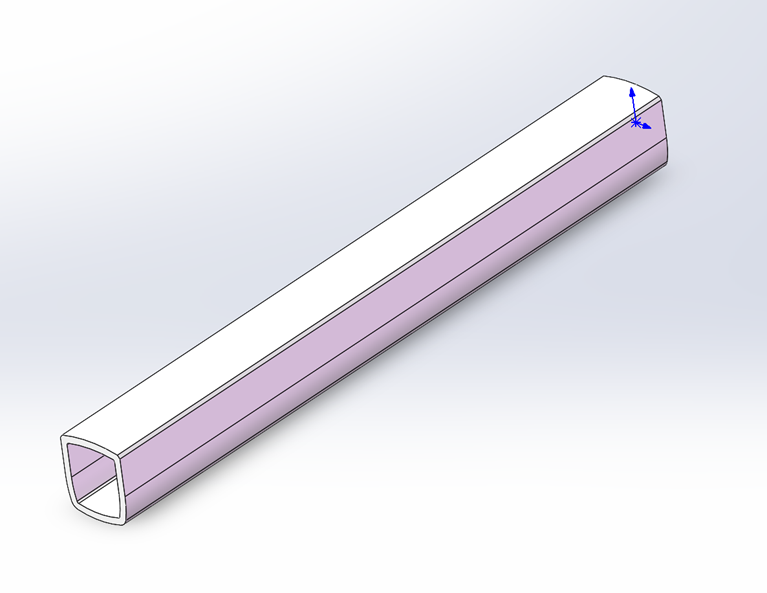

Below are the 3D drawings of extruded mold:

The Font bracket needs to be processed by cnc milling on the machining center, milling grooves, drilling counterholes, etc., and then welded to the cover.

For the Back bracket, another set of bending mold needs to be made, then the grooves are milled on the machining center, the holes are drilled, and the protrudes are welded together, etc.

Here is the picture of rough welded bracket:

Then grind off the welded marks until it is no longer visible, and then polish the entire bracket.

After that they are sent for polishing and black anodized:

Packing

As the products are outer appearance parts, EPE foam is used to separate each one for packaging to avoid problems such as scratches during transportation. Then they are packed in solid carton and laid on the pallet, fixed with strip and protected film to avoid scattering.

For this part, the aluminum process, combines the bending process, and machining process, also the surface treatment are used, whick make the parts very perfect. Ningbo Joyo Metal Products Co., Ltd. is highly skilled at using multiple processes to serve our customers.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски