Product Introduction

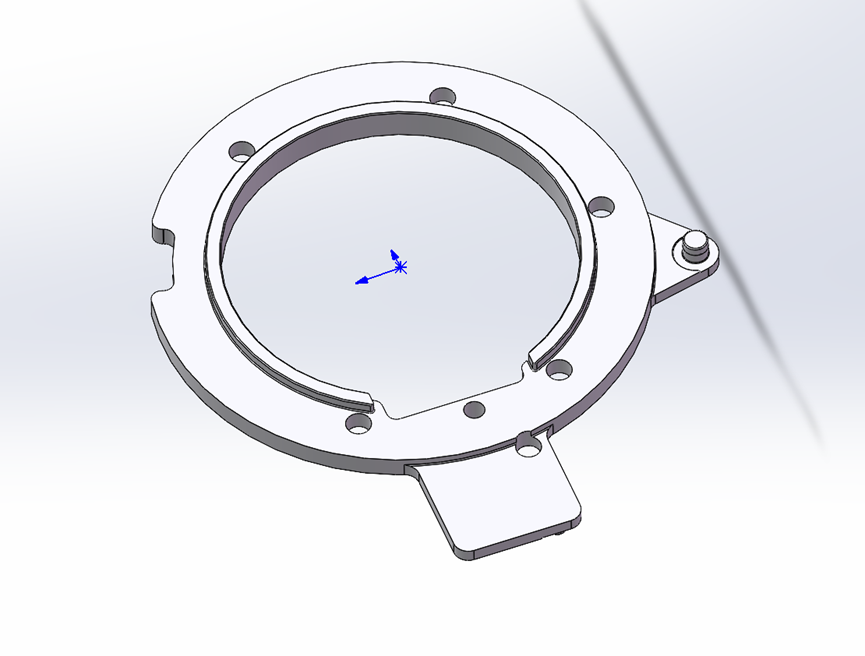

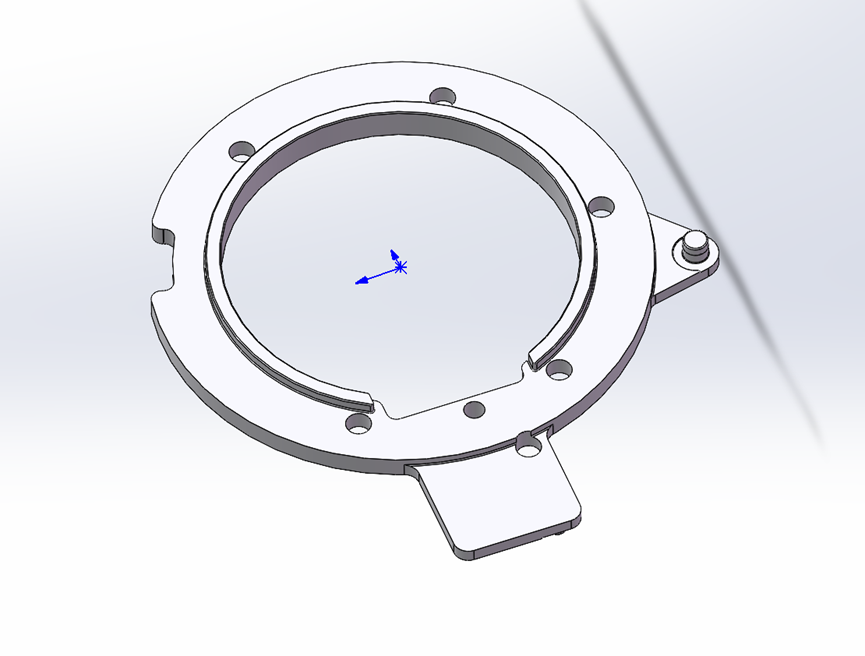

A Custom Aluminum Milled PCB Plate from Billet is a precision machined aluminum plate, which is designed to hold or support printed circuit boards (PCBs), made by CNC milling from a solid aluminum billet. These plates are used in electronics, aerospace, robotics, and other high-performance applications where durability, heat dissipation, and precise mounting are critical.

Material and process

There is a project from our customer, they need the entire plate is processed by a machining center.

The material is 6082-T6 aluminum alloy. It does not require anodizing or sandblasting, just machining surface. The only requirement is producing it according to the drawing strictly.

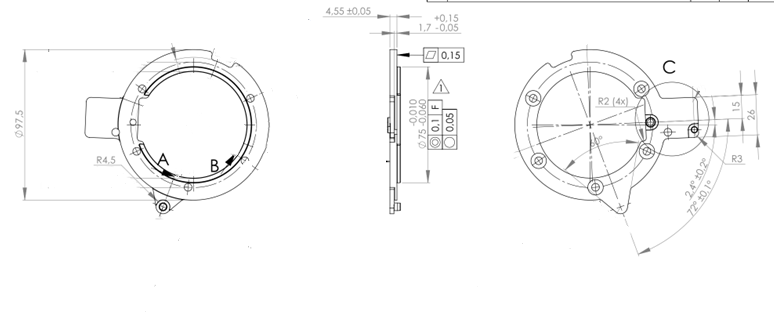

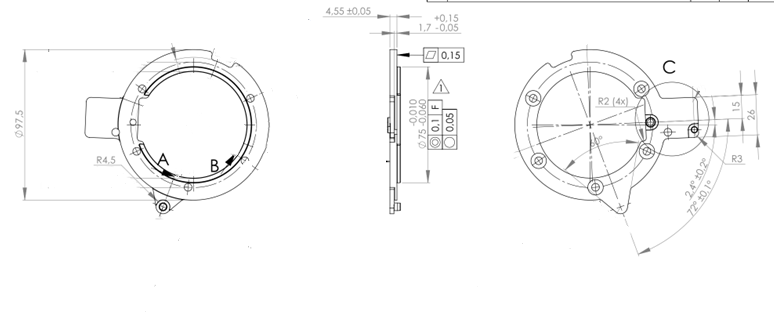

Below is the plate drawings:

The drawing was analyzed carefully. The product is very thin, only 4.55mm, with a tolerance of ±0.05mm.

This requires a very accurate fixture to prevent deformation. This is especially for the outer diameter of 75-0.01/-0.06, which has a tolerance of only 0.05mm. This tolerance level is no problem for our factory. In addition to the tolerance, The concentricity of 0.1mm, roundness of 0.05mm, and flatness of 0.15mm during CNC milling were needed to pay more attention as well. This level is within our control.

Concentricity is the degree of deviation of the center of a circle. It is a special form of coaxiality.

Flatness refers to the degree of flatness of a surface relative to an ideal plane and is usually used to control and measure the shape error of a part surface.

Roundness refers to the degree to which the cross section of a workpiece approaches a theoretical circle. When the difference between the maximum radius and the minimum radius is 0, the roundness is 0.

The lower left corner has a boss with an outer diameter of 4.96 ± 0.02, which is also worth noting. It also has a 4° angle. This tolerance is acceptable for us.

Overall, this product has some machining requirements, but they are within a manageable range.

The key is to ensure a good fixture and prevent product deformation, otherwise the tolerance will be exceeded.

We have already produced five batches of this product, and customers have been very satisfied.

Conclusion

This product has very high requirements and is quite difficult to produce, but Ningbo Joyo Metal Products Co.,Ltd. is still able to overcome difficulties and try our best to meet the requirements. Our process skill is advanced and the quality is guaranteed. Send an inquiry now!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски