Product Instruction

This product is clamp used in wheelchair industry. Clamps play a crucial role in component assembling, they fix the location and adjust the distance. There are many kinds of clamps worked by our company, most are in aluminum material and their surfaces are pretty nice.

Material and process

Most of our clamps are made by extruding 6063-T5 aluminum profiles, while some are machined directly from 6061-T6 billets.

Take our best-selling clamp for example, we make them in huge quantities, using aluminum extrusion cuts down on the amount of material we have to mill away. That saves us a lot on costs! The extrusion process allows to form the basic shape right from the start, so we only need to do minor machining instead of starting from a solid block. It's a way to keep prices low without skimping on quality.

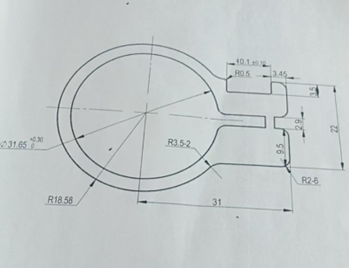

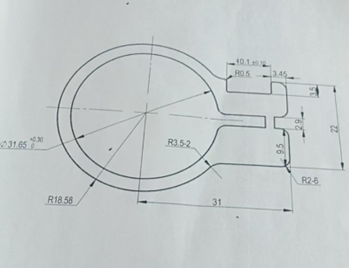

Check out the apprance of the clamp from the drawing.

When extruding aluminum profiles by a die, the hollow structure can causes twisting if not reinforced. To keep dimensions precise, we recommend adding ribs in the groove to help stabilize the profile and prevent warping during processing.

The center hole tolerance 31.65+0.3 is the most important size, we usually to work it in lower tolerance. The real risk is that the hole will become bigger after milled the rib.

However the groove 2.9mm make the client easy to adjust the tightness.

See the picture of assembly, it is fastened with two bolts around tube, so that you can understand how the clamp works.

The bigger clamp is produced by the same processes, but in different mold and different size.

Besides we have other types of aluminum clamps, using CNC milling from aluminum billet, these are used for small quantity, no need to extrude process. 3 axis CNC machine is the best choice to work them, the bolts will help the clamp fasten tight on the tubes.

The clamps are worked from aluminum billet and have sent for sand blasting and black anodizing, which make the finish charming.

Packing

Each product gets a bubble wrap protective layer to prevent scratches during packing and place them into cartons. Cartons are wrapped with film fixed on wooden pallets for stability. We use corner protectors on the pallet edges to prevent damage during forklift operations.

Ningbo Joyo Metal Parts Co,.Ltd is very good at manufacturing all kinds of clamps. Whether it is profile process, machining process, etc., we can handle and custom the metal parts that satisfy the customers.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски