Product Introduction

This trapezoidal threaded shaft is used in the motor controller of our wheelchair, which requires high precision.

It's made from the 304 stainless steel material by CNC machinine process.

1. Material Selection

Primary Material: 304 stainless steel for trapezoidal threaded shaft, CuZn39Pb3 for bushing

Preparation: Cut the stainless steel rod into pieces.

2. Machining process

A. Analyze the drawings

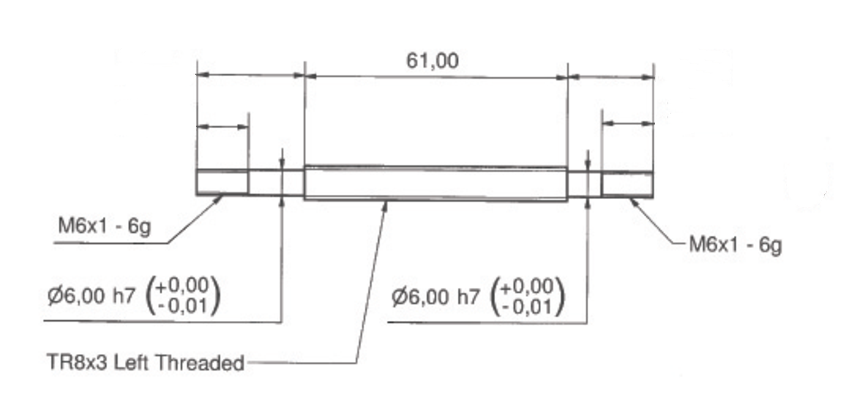

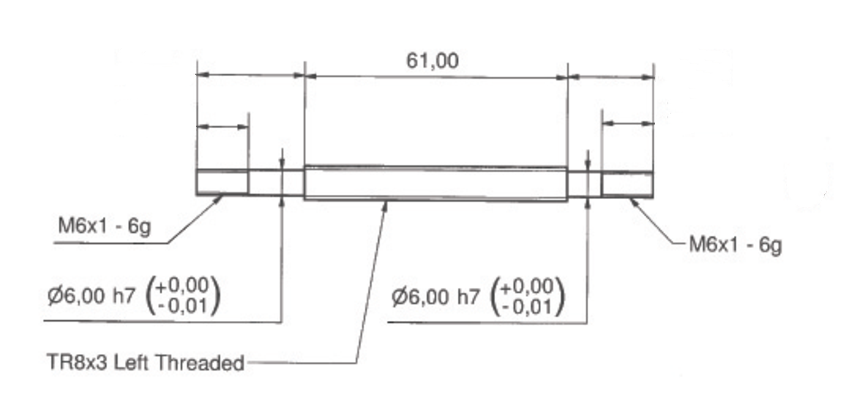

Here is the sketch of the shaft:

The product is very thin, with an outer diameter of only 8mm and a length of 106mm.

The material is standard 304 stainless steel, a material we are highly specialized in processing, although it is prone to sticking to the knife.

B. Machining

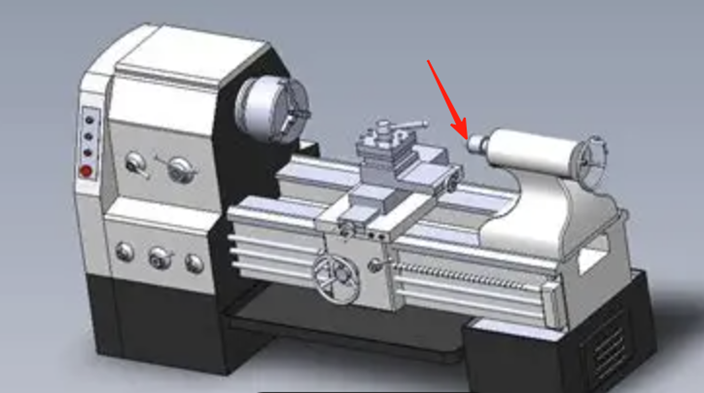

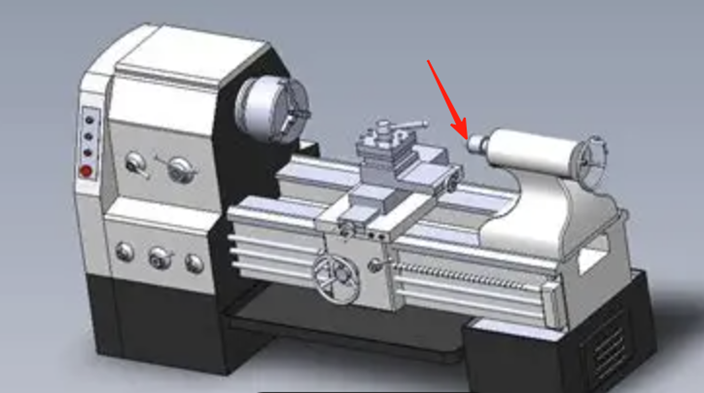

To process this slender product, a locating hole must be drilled in one section, as shown in the image. This allows for a live center to maintain concentricity and maintain stable dimensional tolerances.

The processing of the live center is as shown in the figure below:

The CNC lathes we currently use are very precise. They can turn the outer diameter to a tolerance of 6-0.01mm at once. Then we turn the left-handed trapezoidal thread TR8x3 in the middle, and then roll the threads at both ends after completion.

3. Design Feature

Shaft: Trapezoidal threaded

Bushing: Left-handed trapezoidal threaded hole

Overall design: The thread rotates very smoothly when assembled.

4. Material and Process Specifications

| Parts | Material

| Process |

| Shaft | 304 stainless steel | CNC machining |

| Bushing | CuZn39Pb3 | CNC turning |

5. Processing & Assembly Method

The video shows how to assemblye:

6.Conclusion

This case shows our extensive experience in processing trapezoidal threads, both left-hand and right-hand.

Ningbo Joyo Metal Products Co., Ltd. also maintain exceptional precision to 0.01mm.

Customers can definitly trust us with the level of precision.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски